Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on SCT1300

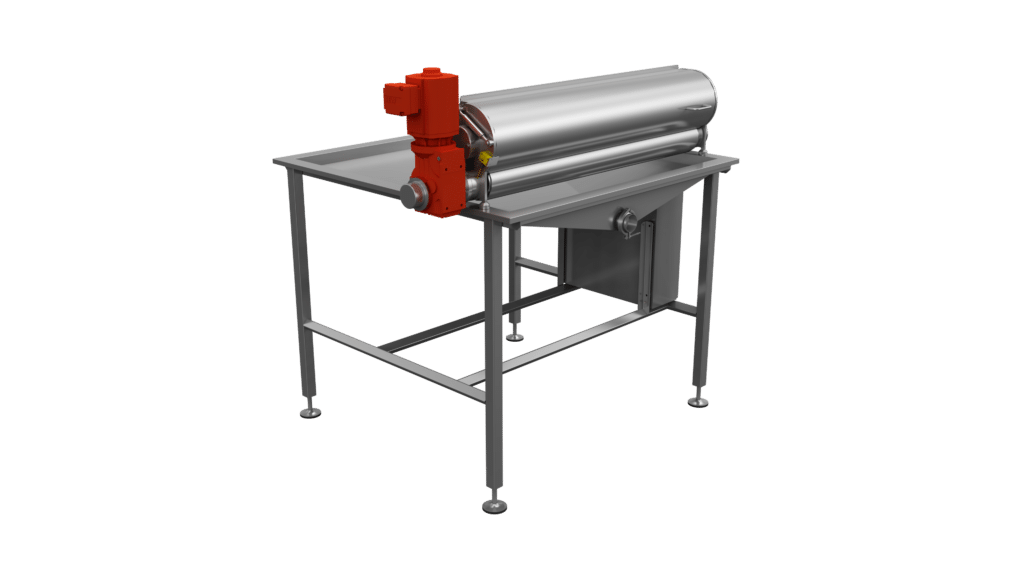

Maximise product recovery from Polyliner bags

Does your industry wish to recover valuable product from Polyliner bags for more sustainability and profit?

The Fluidor Bag Squeezer SCT1300 is a stand-alone machine, designed to squeeze emptied Polyliners with product, to reduce product loss to a bare minimum (< 0,1 %). The STC1300 handles Polyliners from 10 to 1.000 litres (EU) or 2,7 to 265 gallons (USA).

Depending on the Polyliner, product and operator, the machine can handle up to 30 liners per hour.

How the Bag Squeezer SCT1300 works:

- Squeezer covers are protected by safety switches and can be opened after production for easy cleaning.

- Operator takes care of the infeed and outfeed of Polyliners.

- The machine is equipped with a collecting tray with an outlet at one side. Directly underneath this outlet, an open drum can be placed to collect the product.

Cost-effective

The SCT1300 squeezes product from larger emptied Polyliners, reducing product loss to less than 0.1%. For optimal product recovery and significant cost savings.

Easy to use & clean

The SCT1300 has a manual infeed and outfeed, with easily openable covers for cleaning. Ensure minimal downtime and efficient use of labour.

Hygienic & safe

The SCT1300 has safety switches on the squeezer covers and an easy-to-clean design. For a safe working environment and high hygiene standards.

Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on SCT650

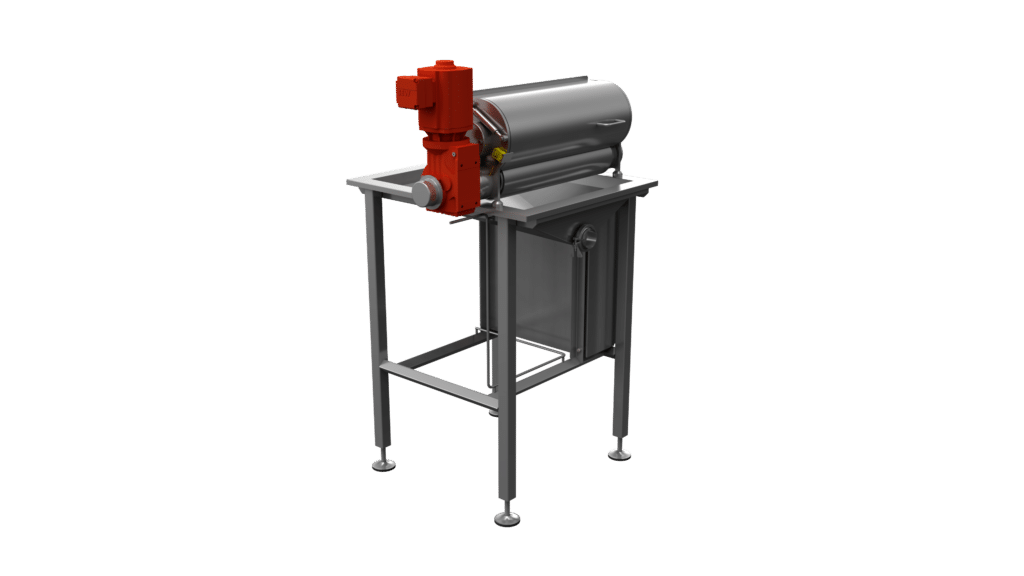

Maximise product recovery from Polyliner bags

Does your industry wish to recover valuable product from Polyliner bags for more sustainability and profit?

The Fluidor Bag Squeezer SCT650 is a stand-alone machine, designed to squeeze emptied Polyliners with product, to reduce product loss to a bare minimum (< 0,1 %). The SCT650 is suitable for Polyliners from 10 to 200 litres (EU) or 2,7 to 52 gallons (USA).

Depending on the Polyliner, product and operator, the machine can handle up to 60 liners per hour.

How the Bag Squeezer SCT650 works:

- Squeezer covers are protected by safety switches and can be opened after production for easy cleaning.

- Operator takes care of the infeed and outfeed of Polyliners.

- The machine is equipped with a collecting tray with an outlet at one side. Directly underneath this outlet, an open drum can be placed to collect the product.

Cost-effective

The SCT650 squeezes product from emptied Polyliners, reducing product loss to less than 0.1%. For maximum product recovery, leading to significant cost savings by reducing waste.

Easy to use & clean

The SCT650 has a manual infeed and outfeed, with easily openable covers for cleaning. Ensure minimal downtime and efficient use of labour.

Hygienic & safe

The SCT650 has safety switches on the squeezer covers and an easy-to-clean design. For a safe working environment and high hygiene standards.