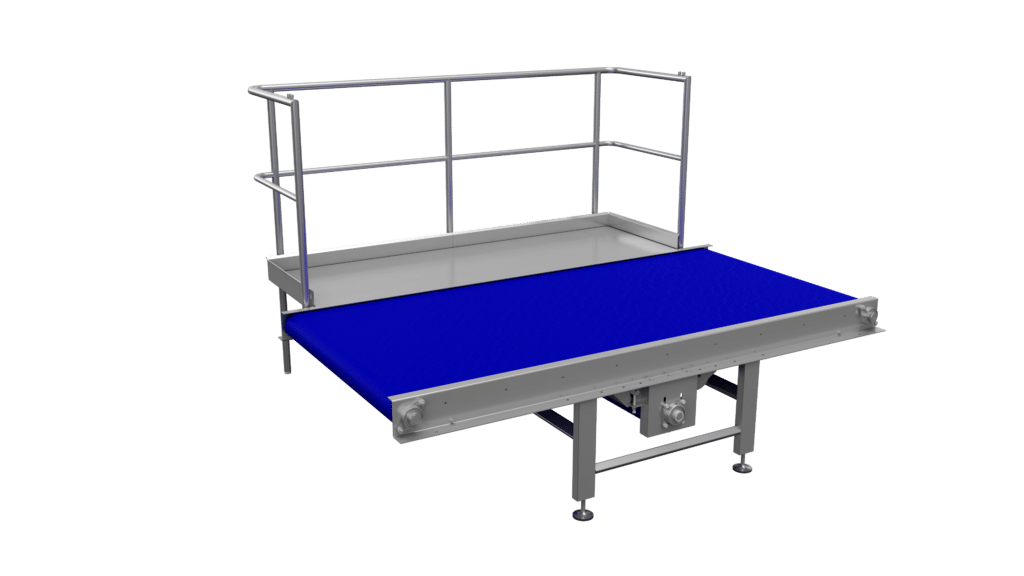

CONVEYOR SYSTEM

Discover our conveyor systems

Transport safely & efficiently

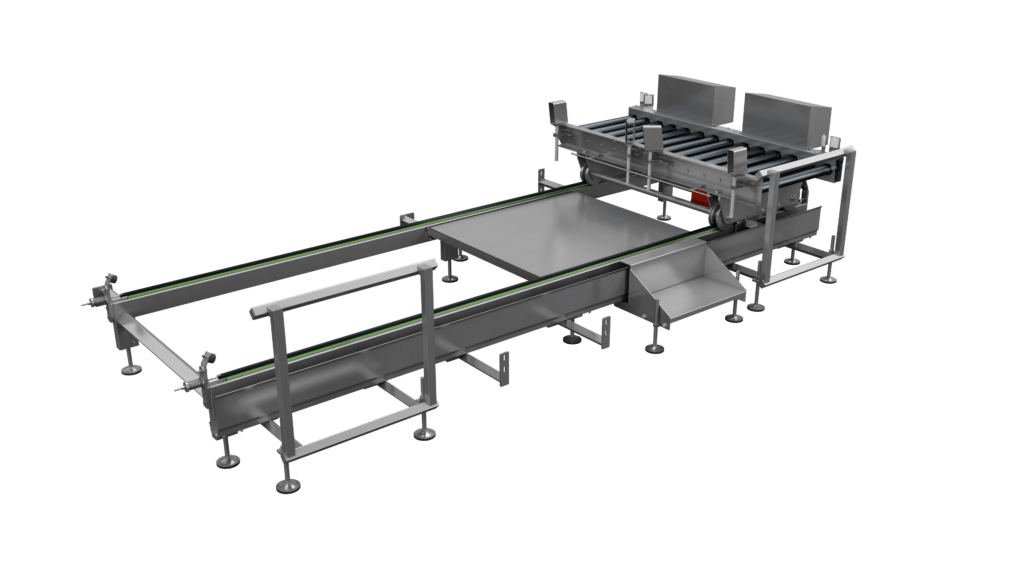

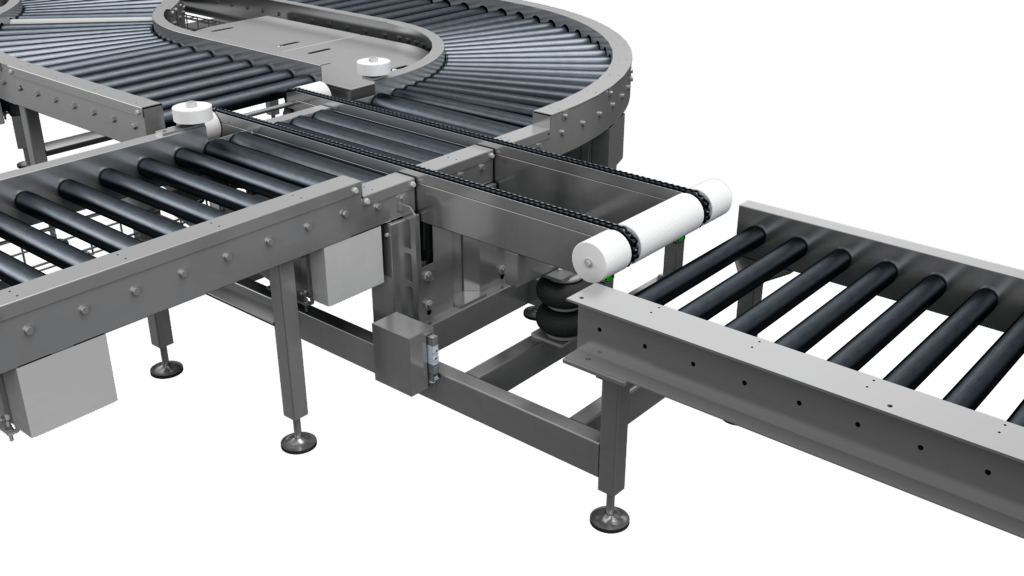

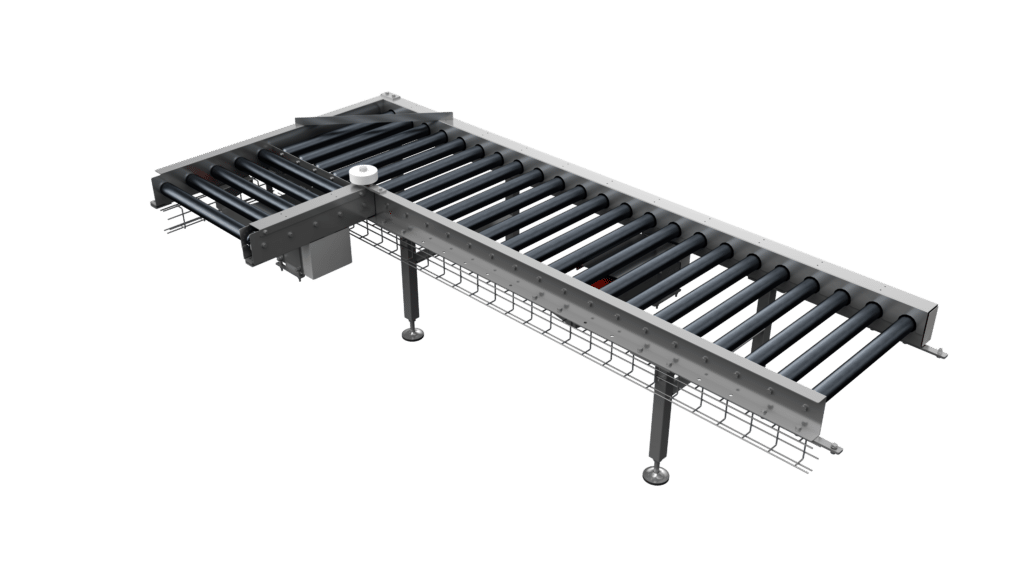

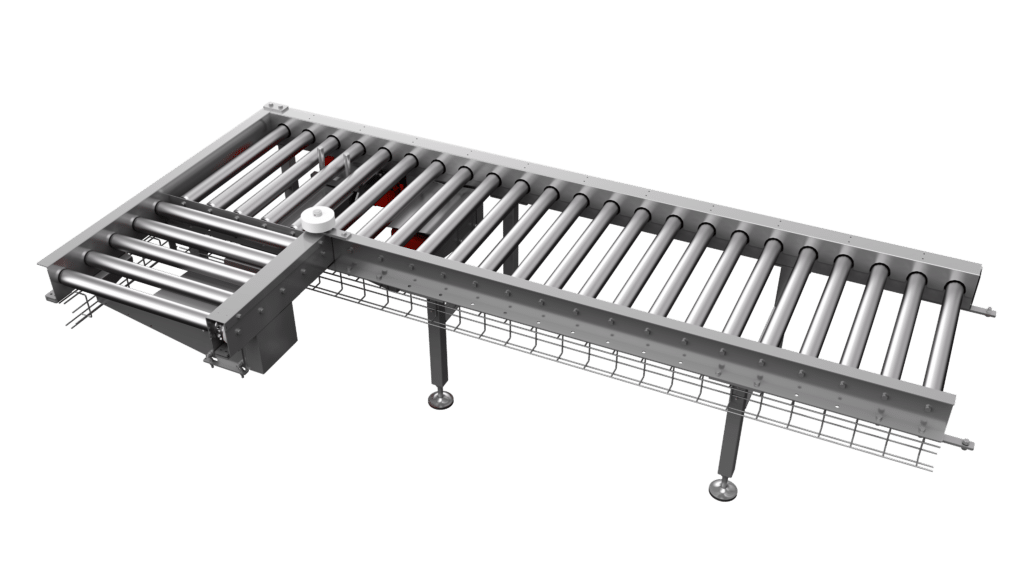

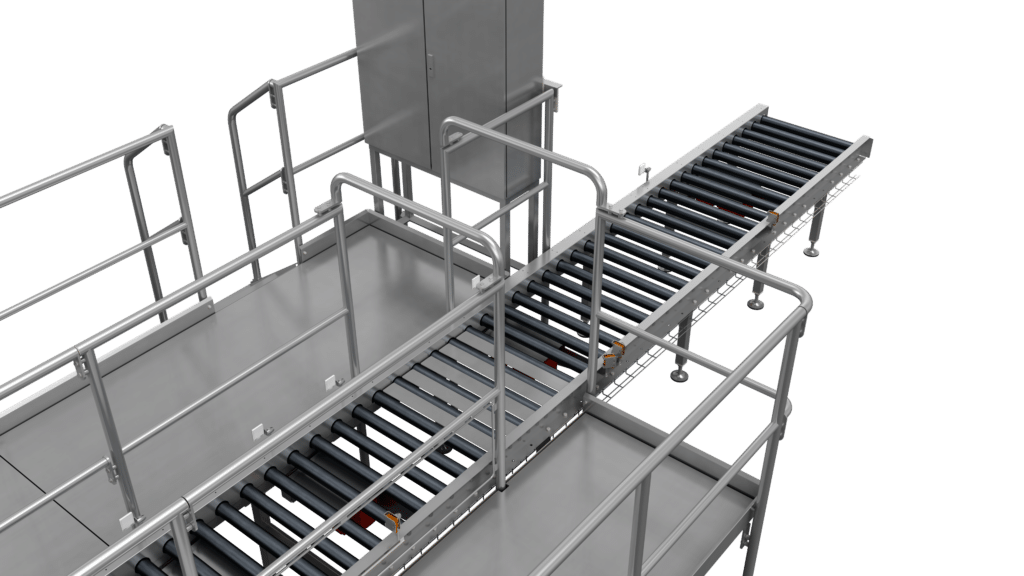

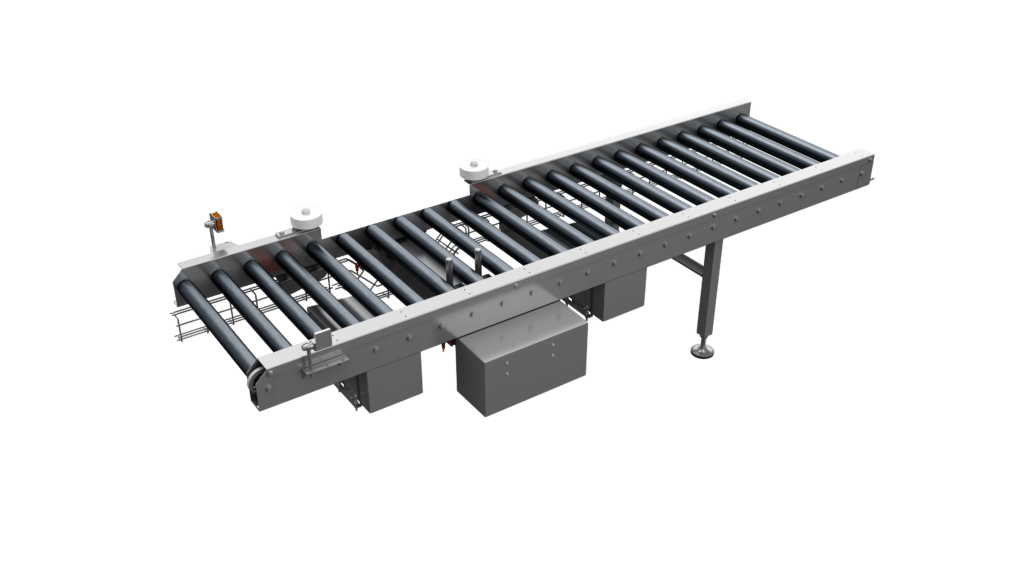

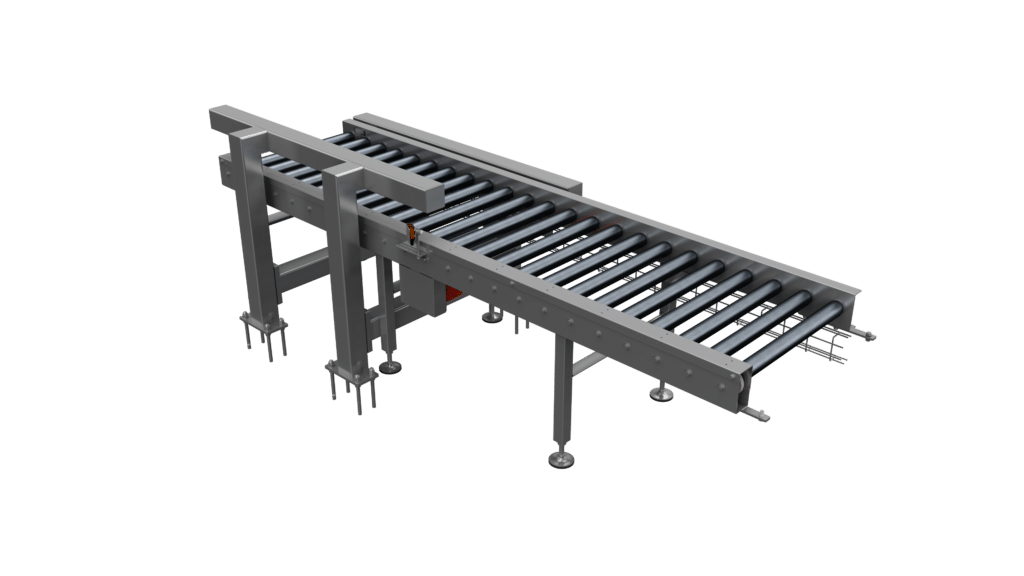

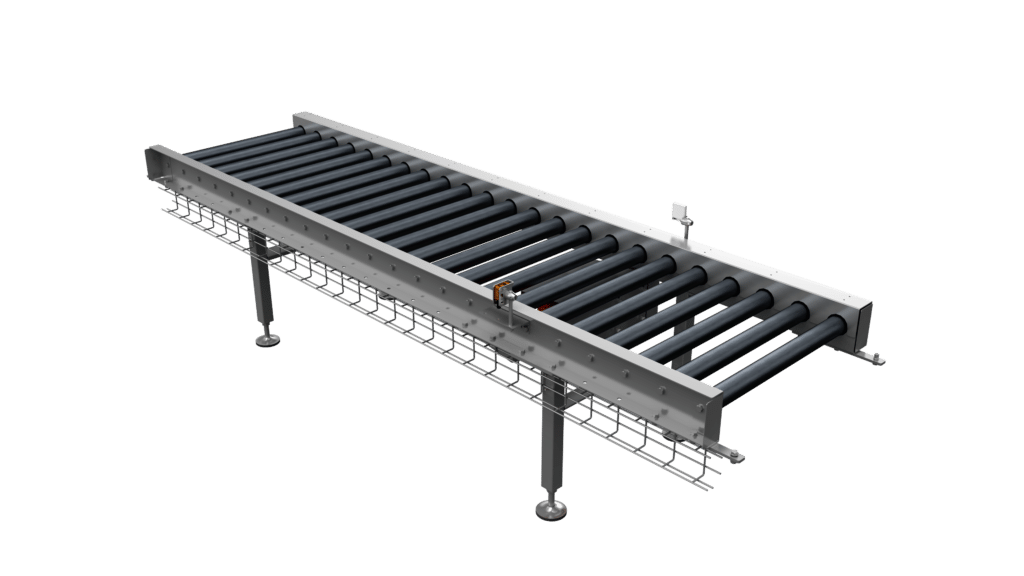

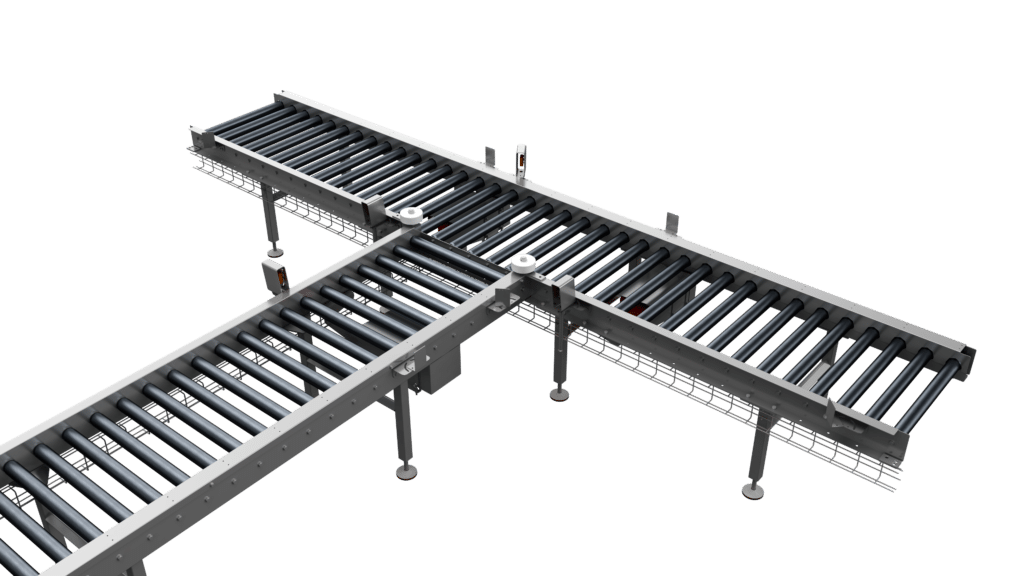

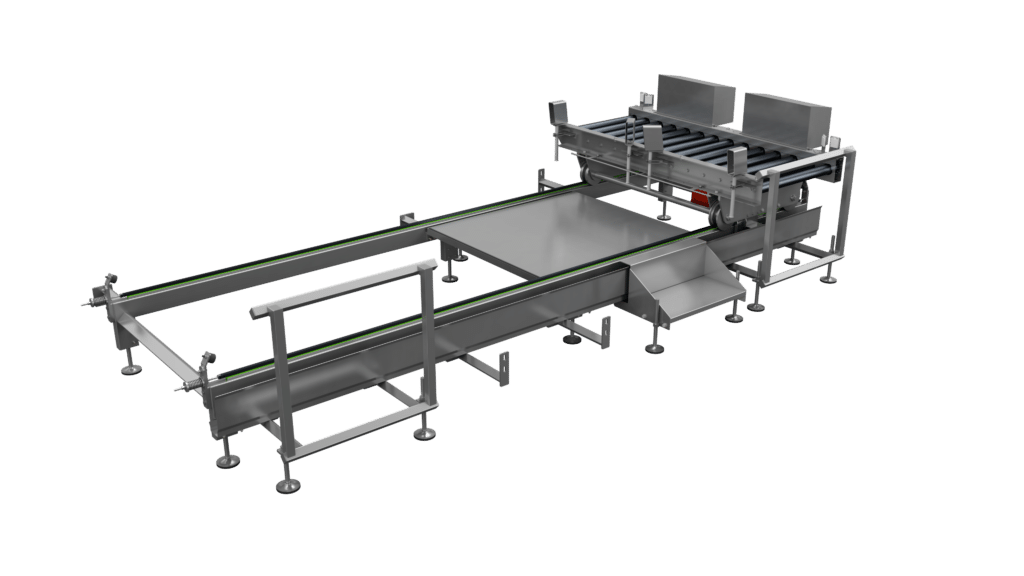

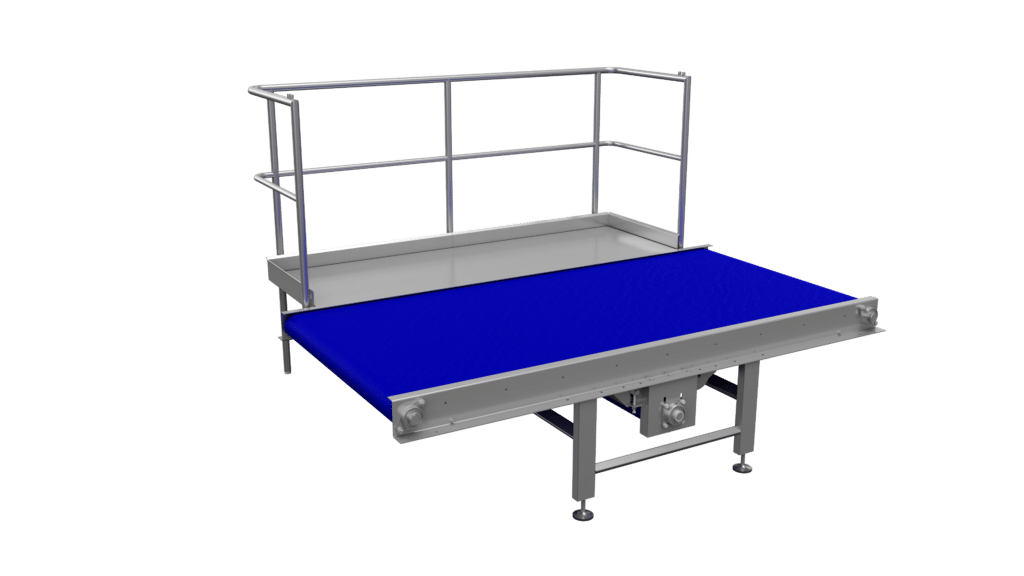

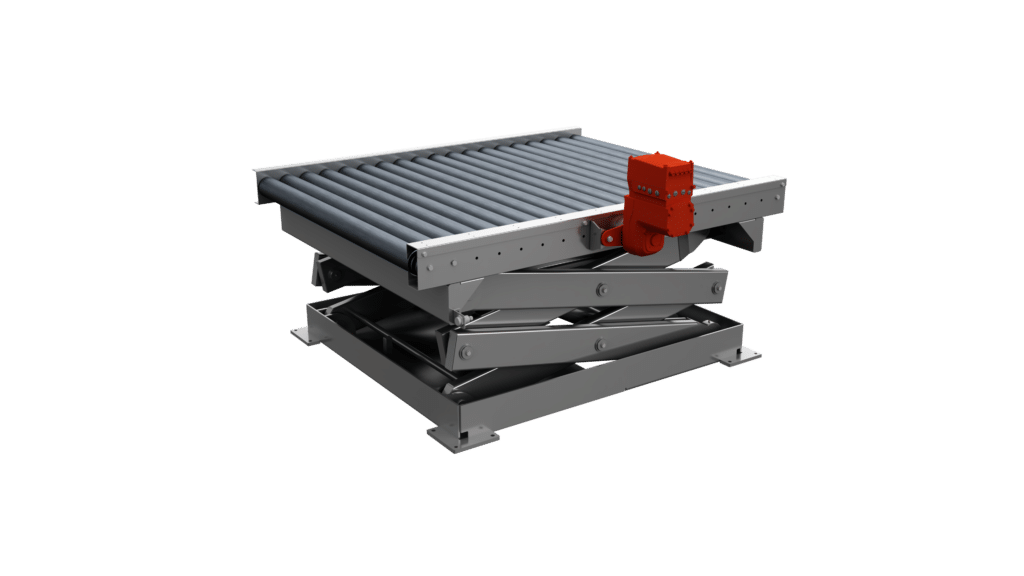

With Fluidor’s Roller Conveyor Systems you can transport raw materials safely and efficiently from one location to another. Our roller conveyors increase the efficiency, flexibility, cost-effectiveness and safety of your internal transport.

Conveyor systems >

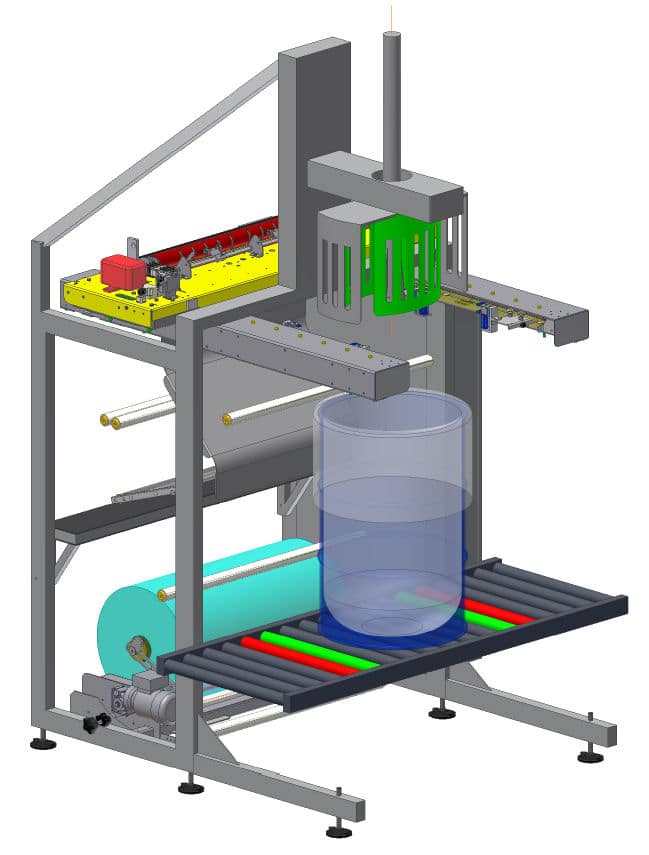

Connect to all types of Dumping Systems manufactured by Fluidor Equipment, available for 200 litre drums and 1.000 litre boxes or tote bins.

The power of Fluidor Equipment

Companies from more than 80 countries around the world rely on the experience and expertise of Fluidor Equipment. Our machines are designed and made in the Netherlands to streamline your process and maximise your productivity for years to come. Discover the power of Fluidor Equipment:

- Efficient: Process faster, more effectively and more economically.

- Reliable: Perform consistently, with minimal downtime.

- Sustainable: Save valuable product, energy, water, time and waste.

- Easy: Simple from integration to cleaning and maintenance.

- Safe: High quality machines, certified food safe.

- Flexible: Applicable for all types of products and processes.

Applications for conveyor systems

- Packaging and containers

- Bottles and cans

- Bags

- Boxes and packages

- Pallets

- Parts and components

TELL ME MORE

CONTACT ME

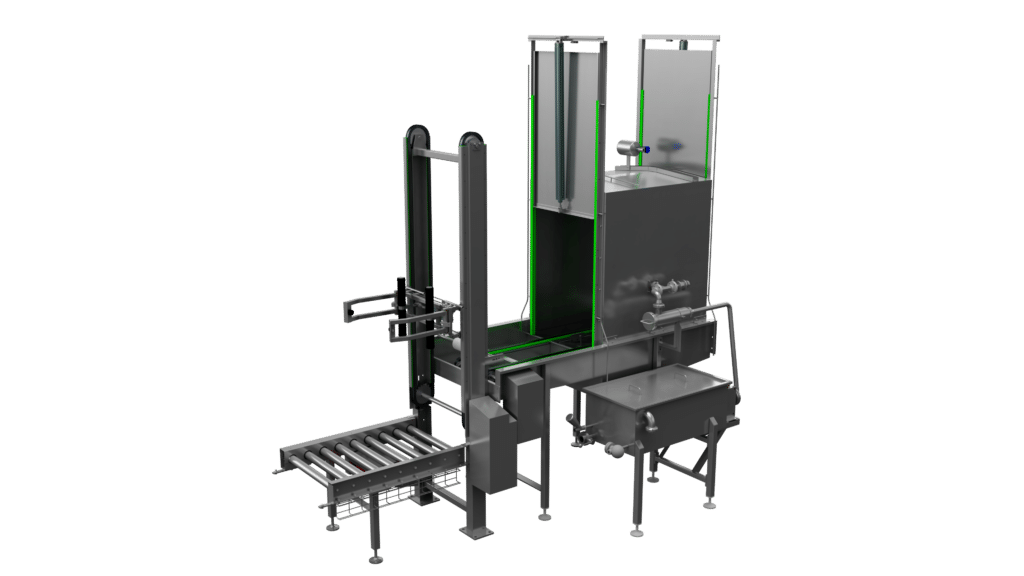

Drum automatic bag inserter

Drum conveyor bag opening station

Drum conveyor bag removal station

Drum chain transfer

Drum conveyor bend

Drum conveyor corner section

Drum conveyor corner section with pusher

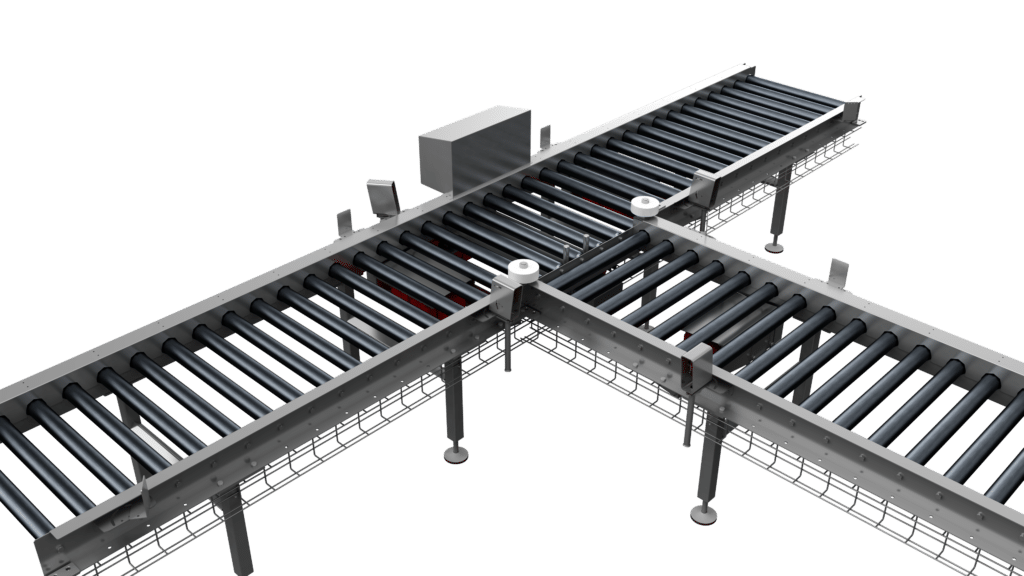

Drum conveyor cross-over

Drum conveyor cross-over platform

Drum conveyor in-out

Drum conveyor loading full drums

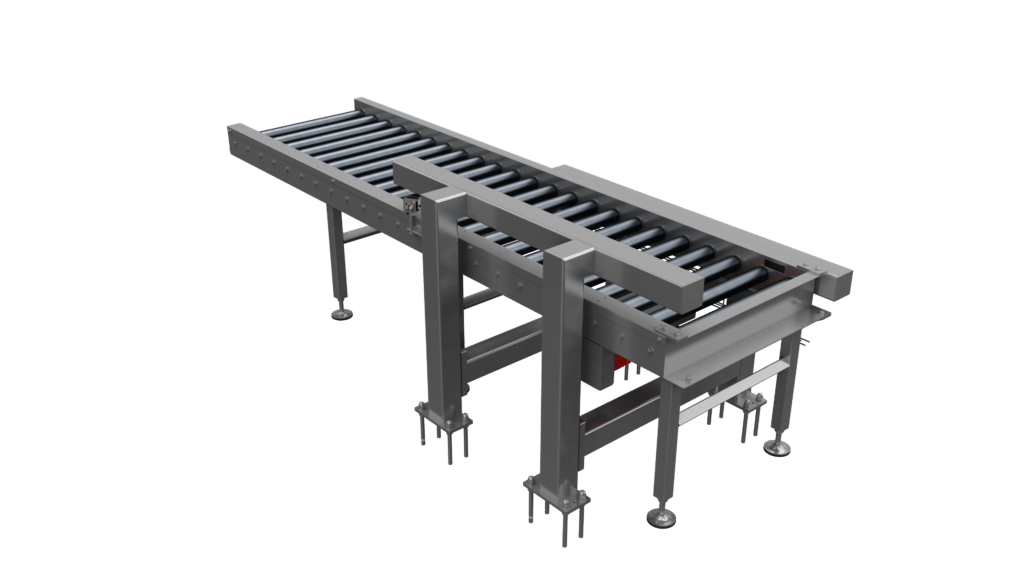

Drum conveyor straight

Drum conveyor T-section

Drum conveyor T-section with pusher

Drum conveyor unloading empty drums

Drum conveyor unloading full drums

Drum crusher

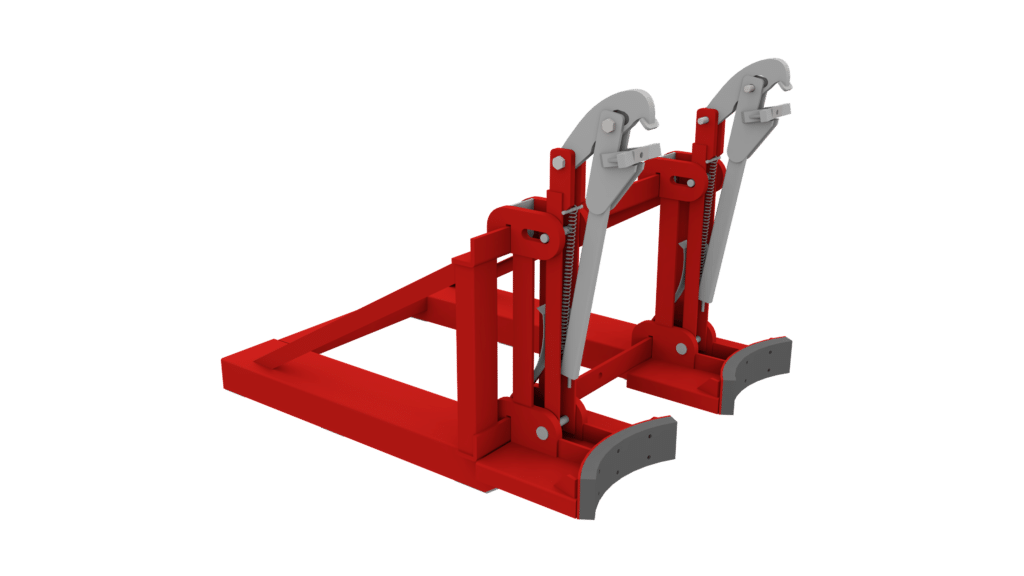

Drum gripper

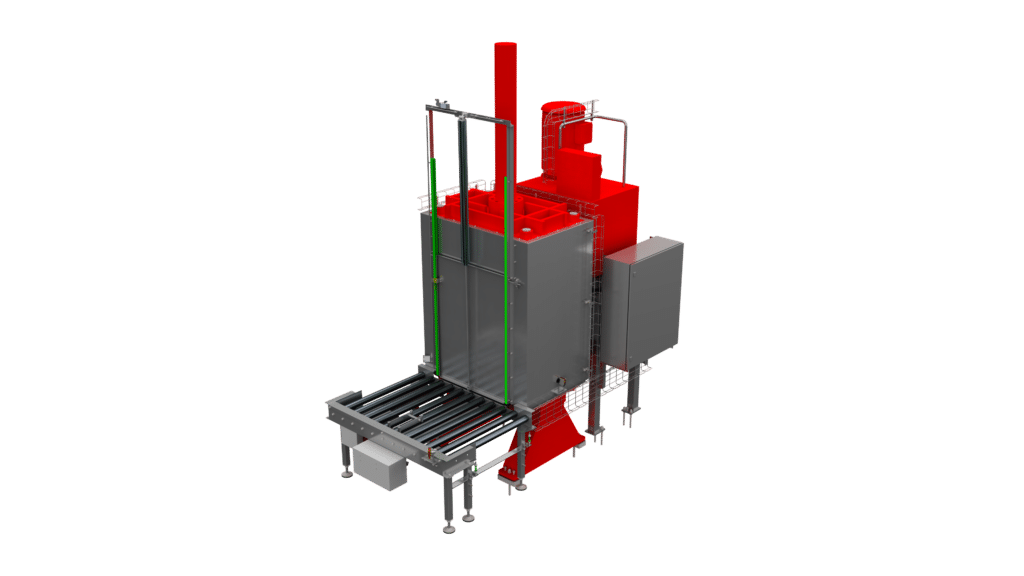

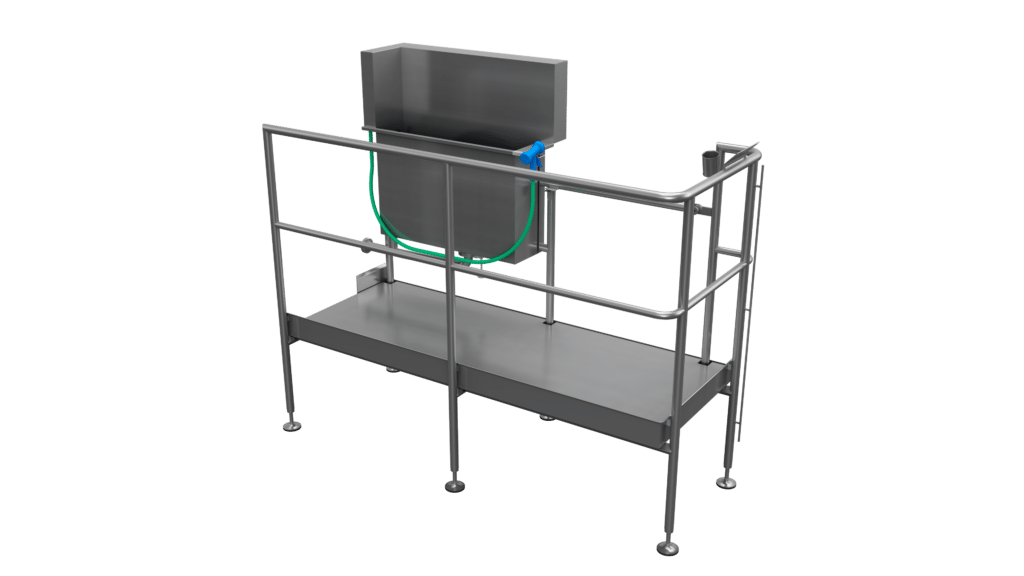

Drum lid wasstation

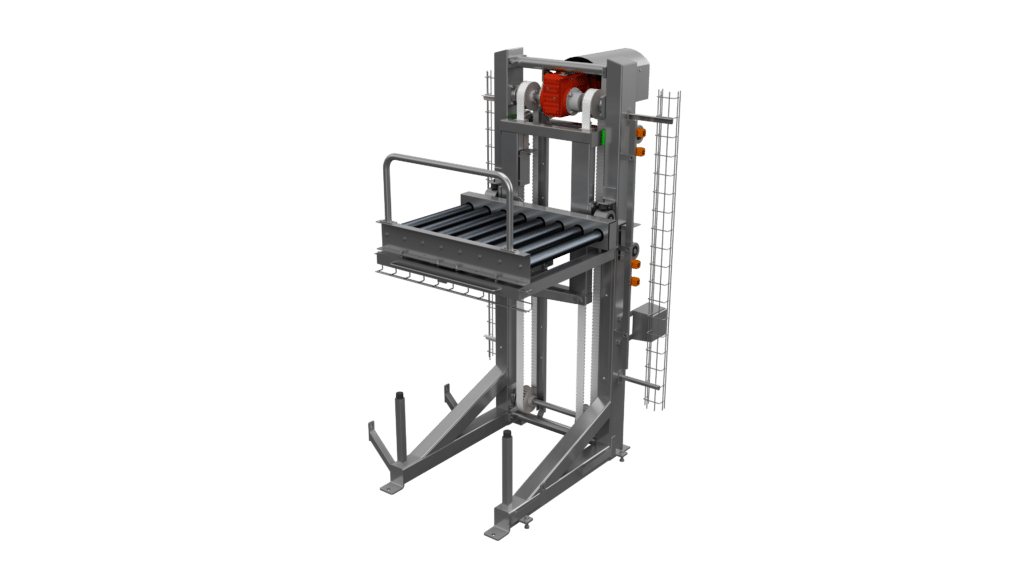

Drum lift

Drum opening station

Drum shuttle

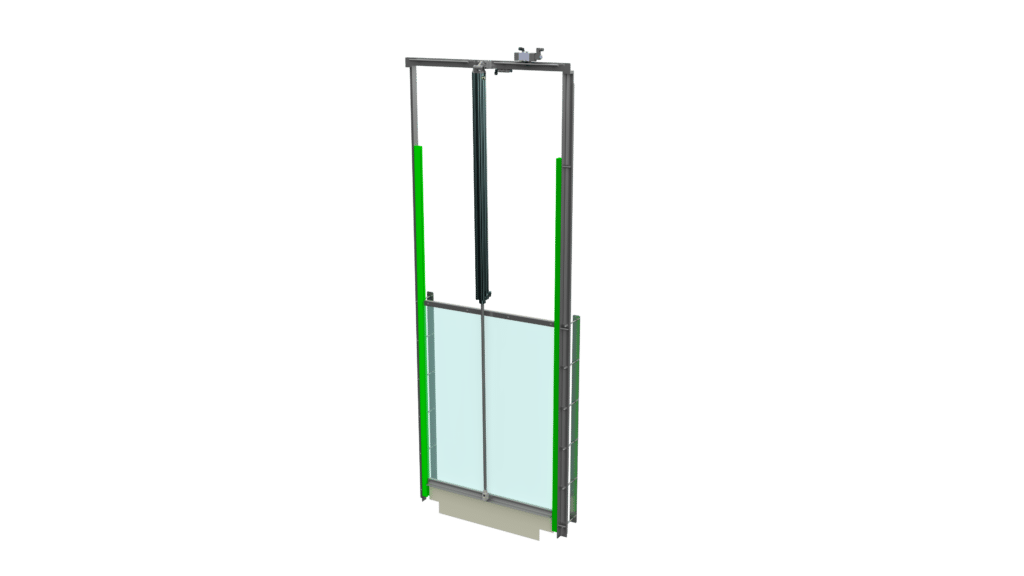

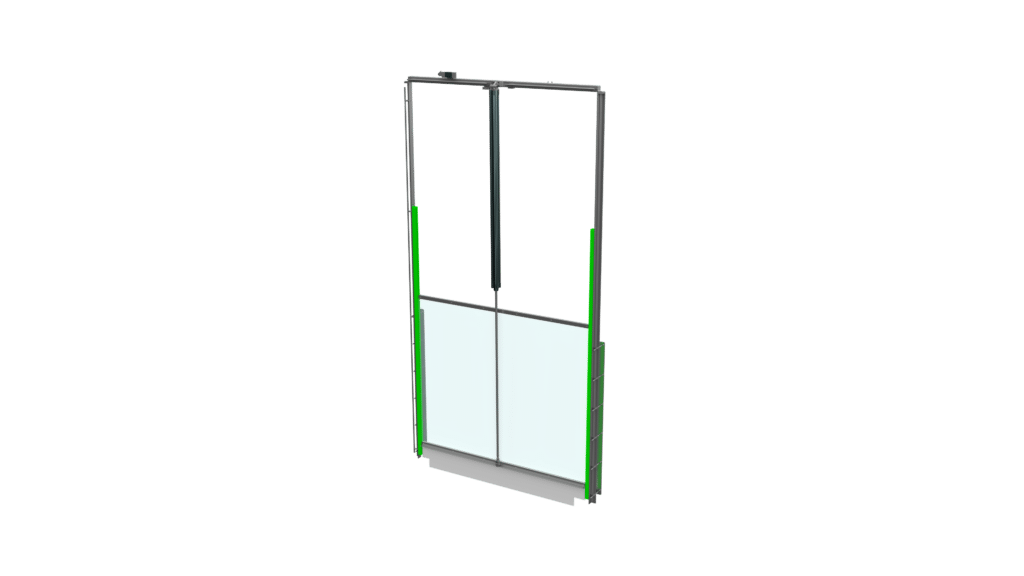

Drum sliding door

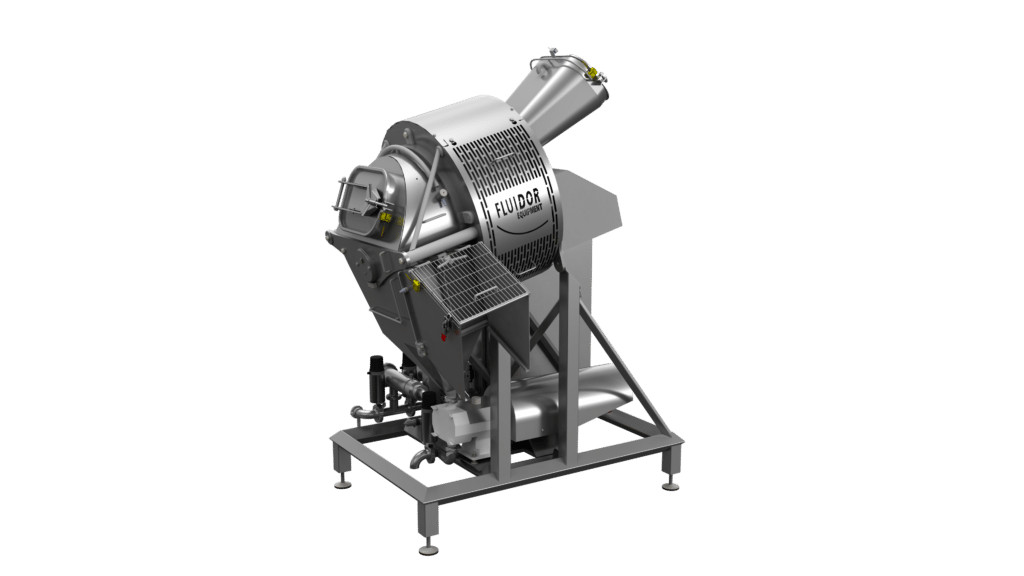

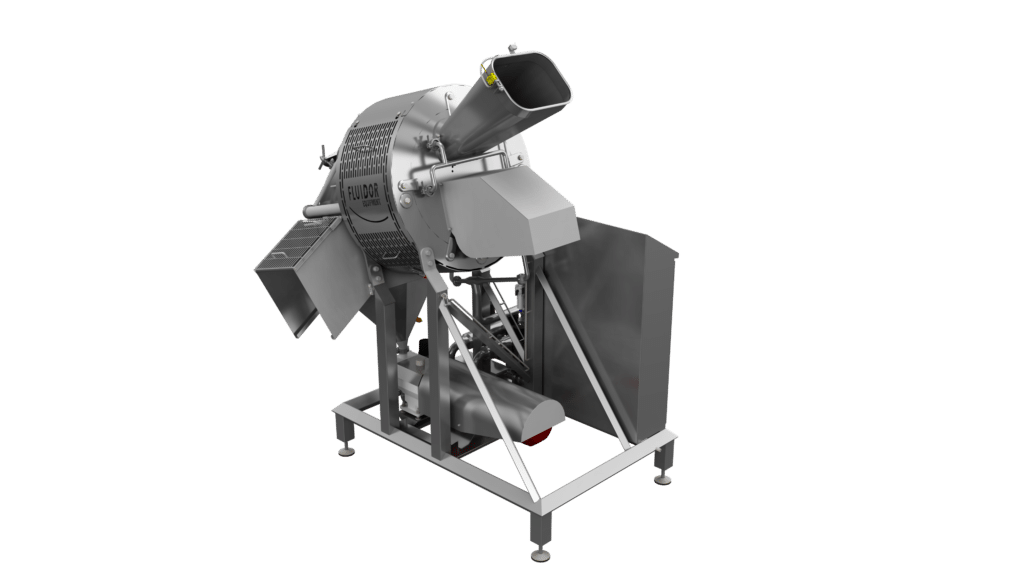

Drum tipper

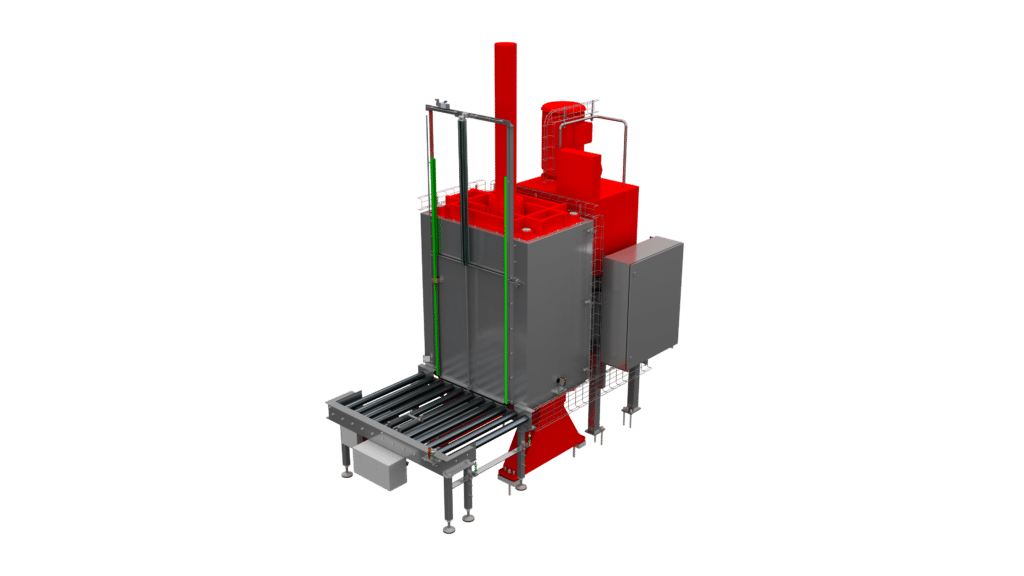

Drum washer empty drums

Drum washer full drums

Drum weighing system

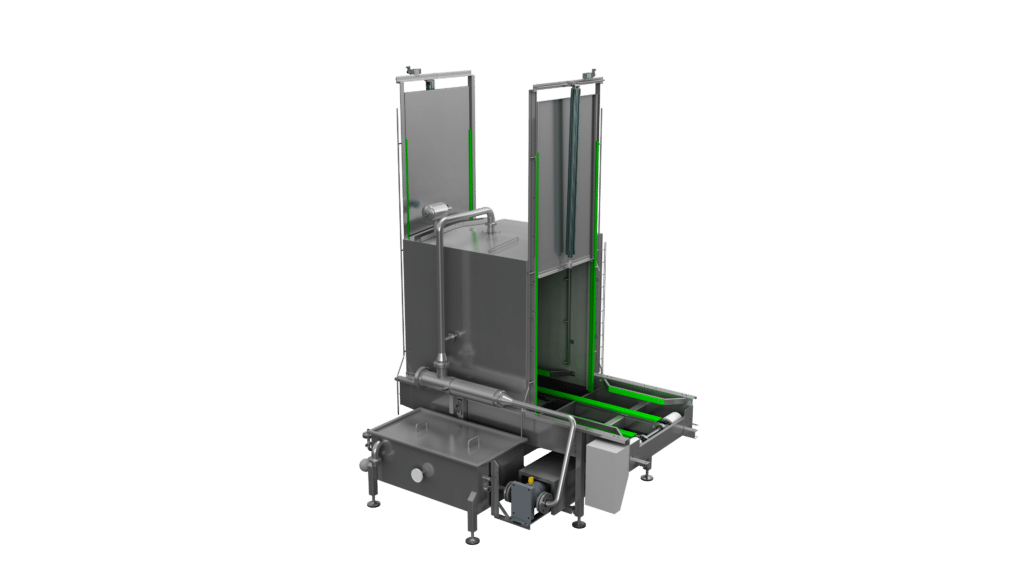

BIN bag opening station

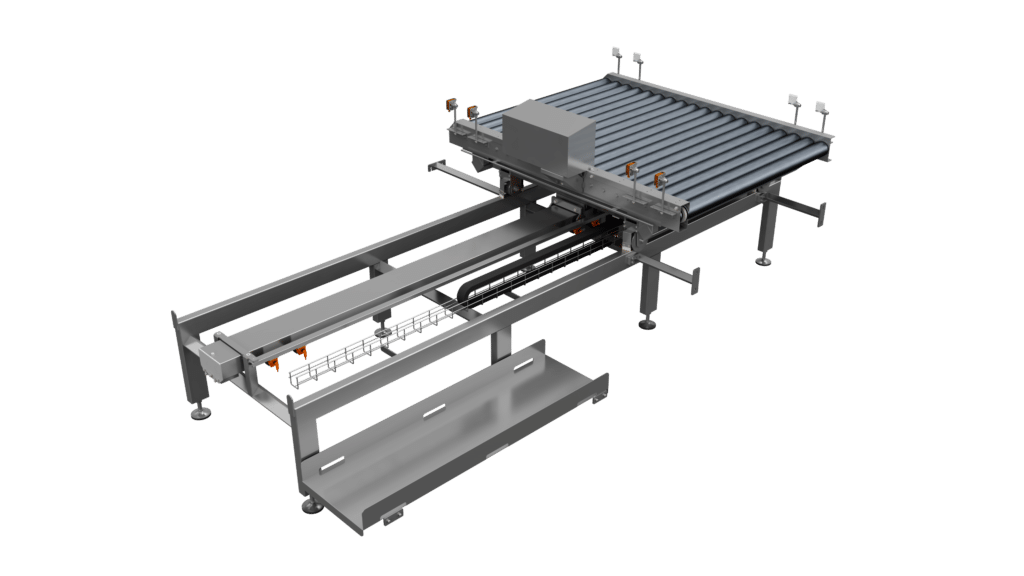

BIN conveyor load unload

BIN conveyor loading

BIN conveyor straight

BIN conveyor unloading

BIN lift

BIN opening station

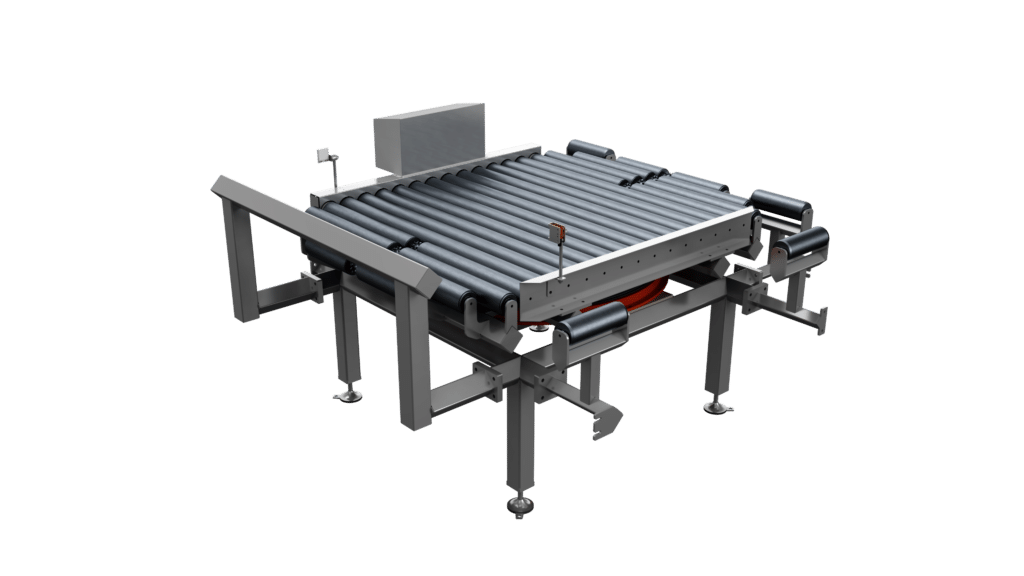

BIN rotation table

BIN shuttle

BIN sliding door

BIN weighing section

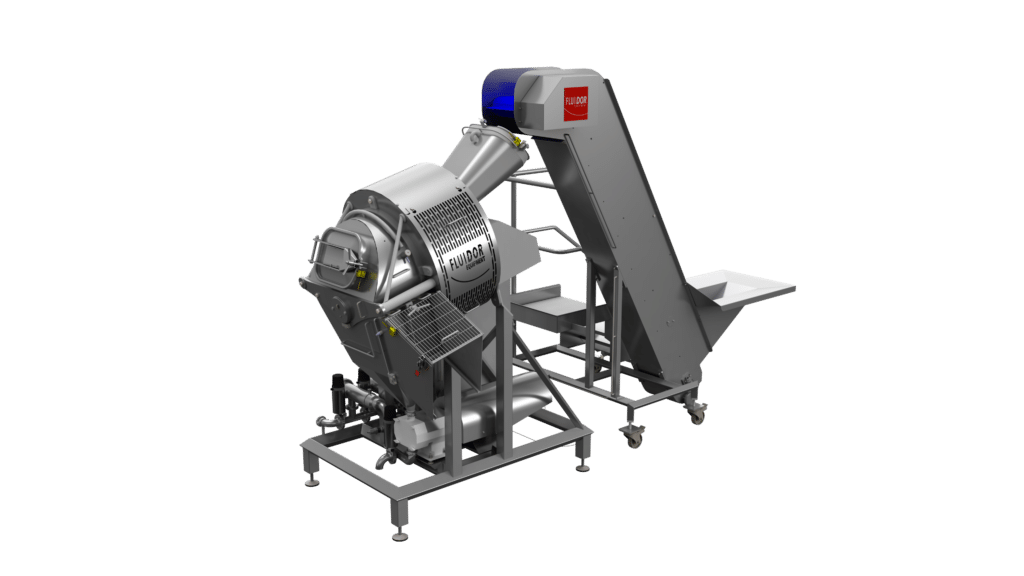

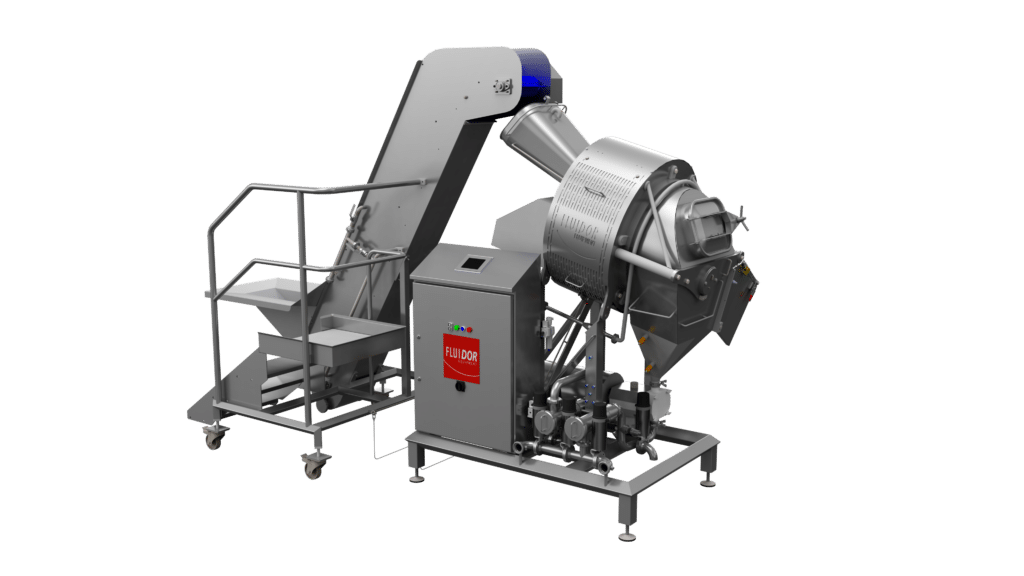

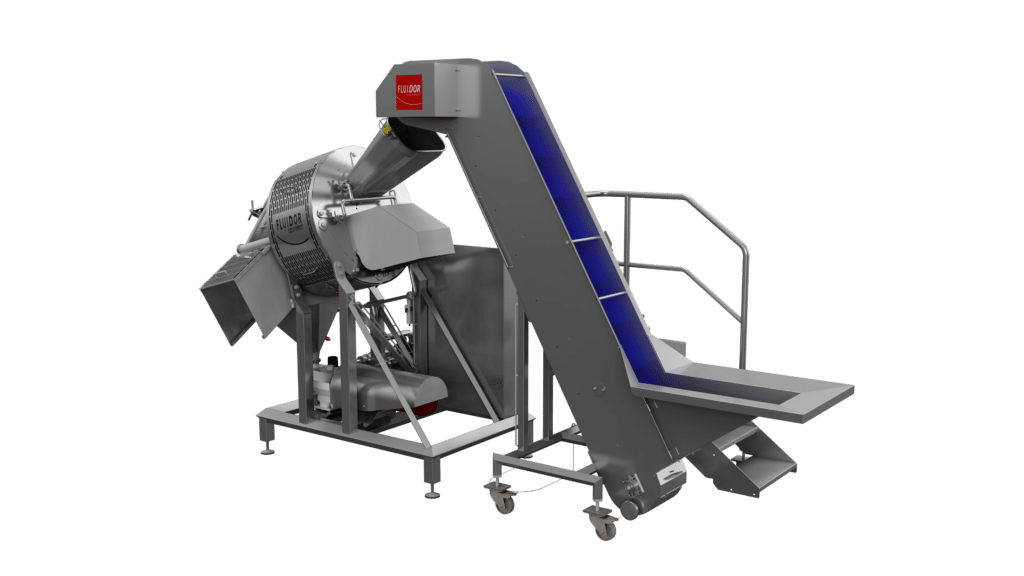

BMPS loading conveyor

BMPS-Paste loading conveyor