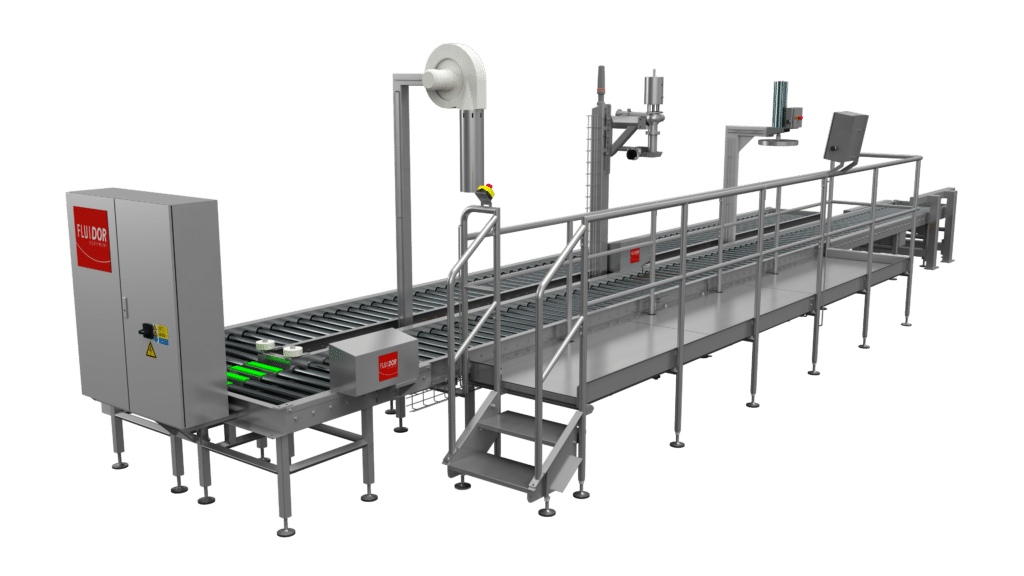

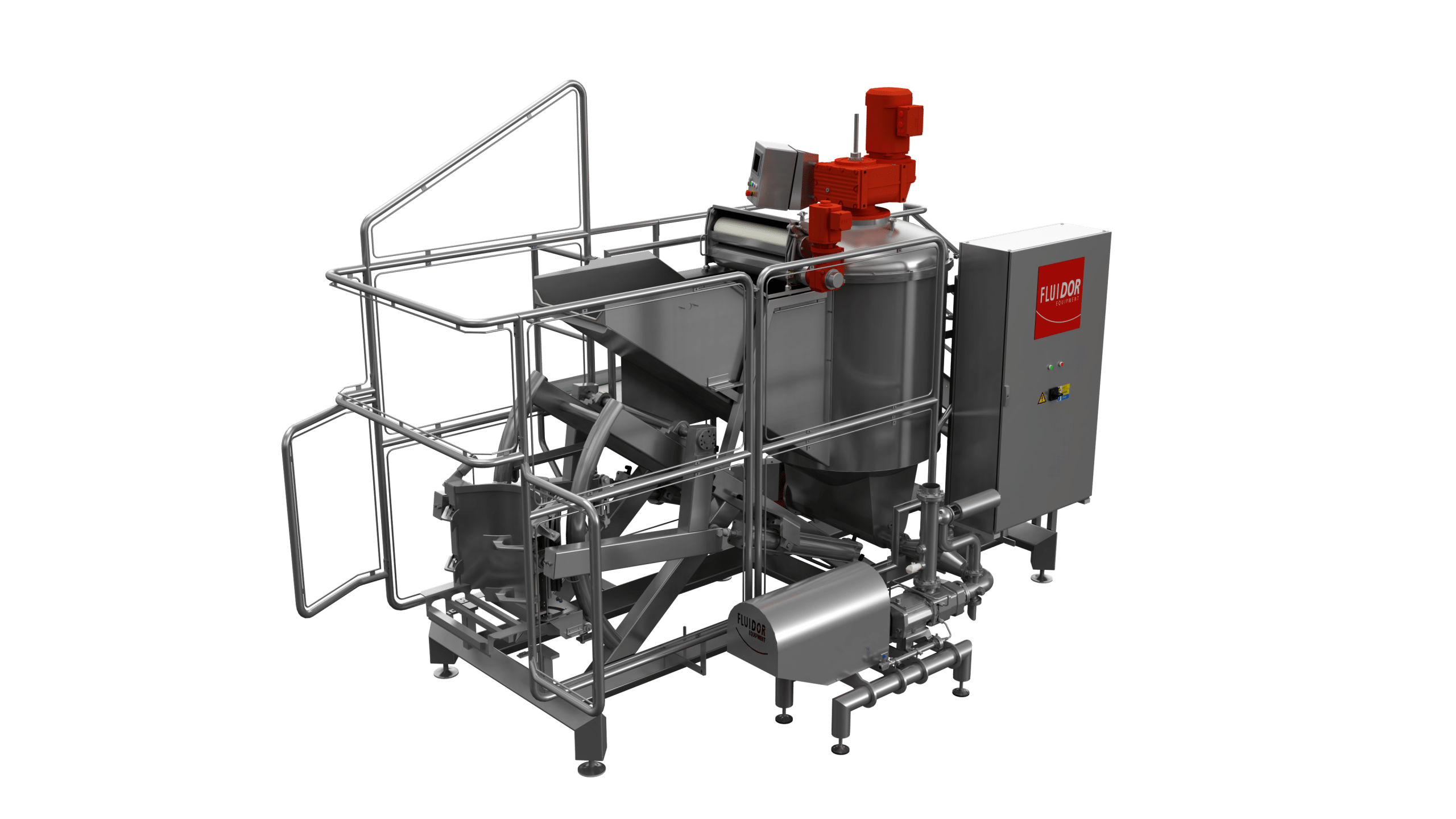

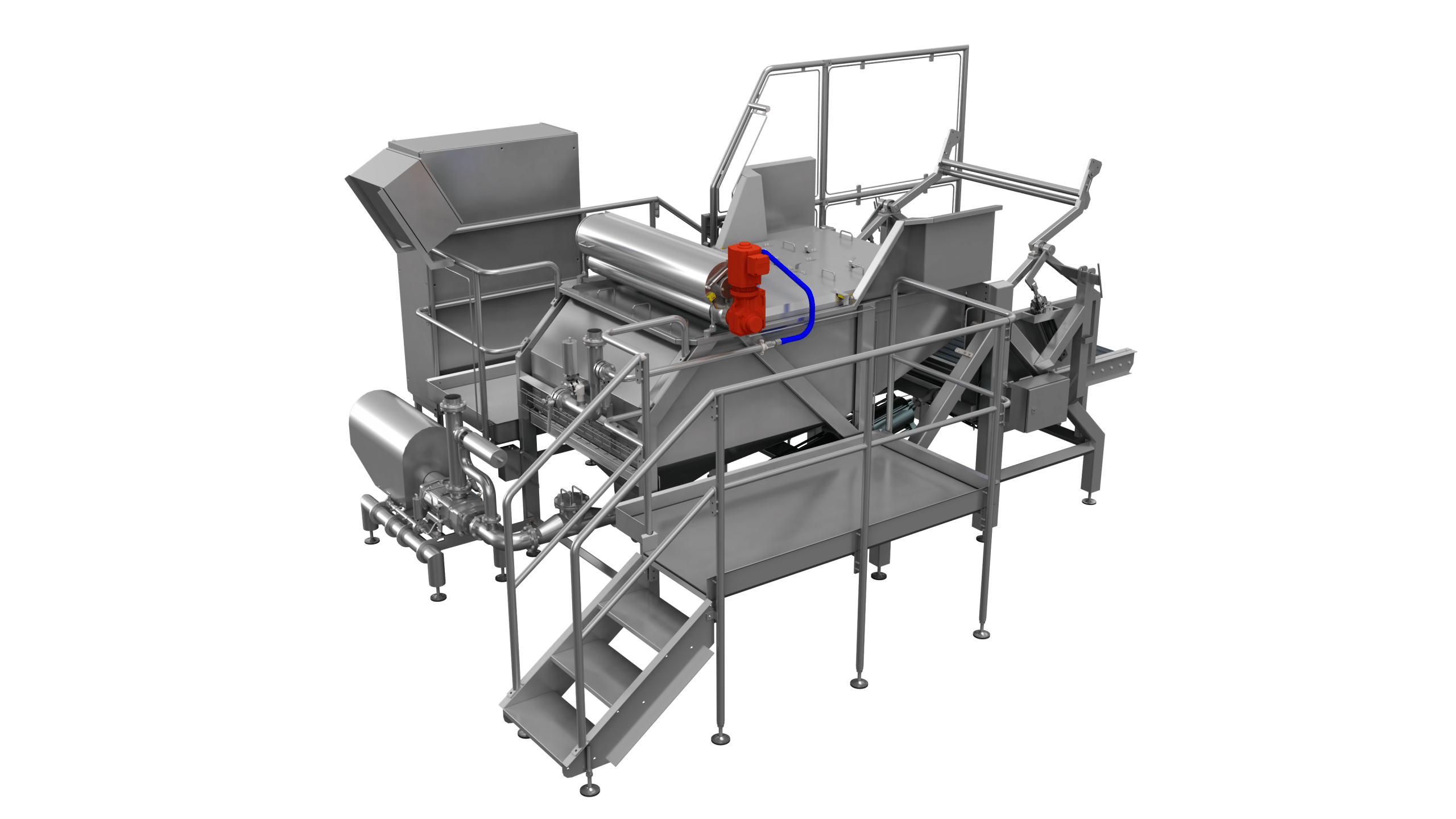

Filling line for drums

With the Filling line for drums, you can fill drums with liquids precisely and efficiently. Minimise waste and ensure product consistency.

Fill drums precisely and efficiently

Does your industry require precise filling of drums with liquids like fruit juice, for production or storage purposes? The Filling line for drums from Fluidor Equipment is designed to fill your drums safely, efficiently and precisely.

The Filling line for drums is designed for efficient dynamic filling of 200 litre drums with fruit juices, fruit juice concentrates or blends with a viscosity up to 15.000 cP. Depending on the infeed and your product, it can handle up to 60 drums per hour.

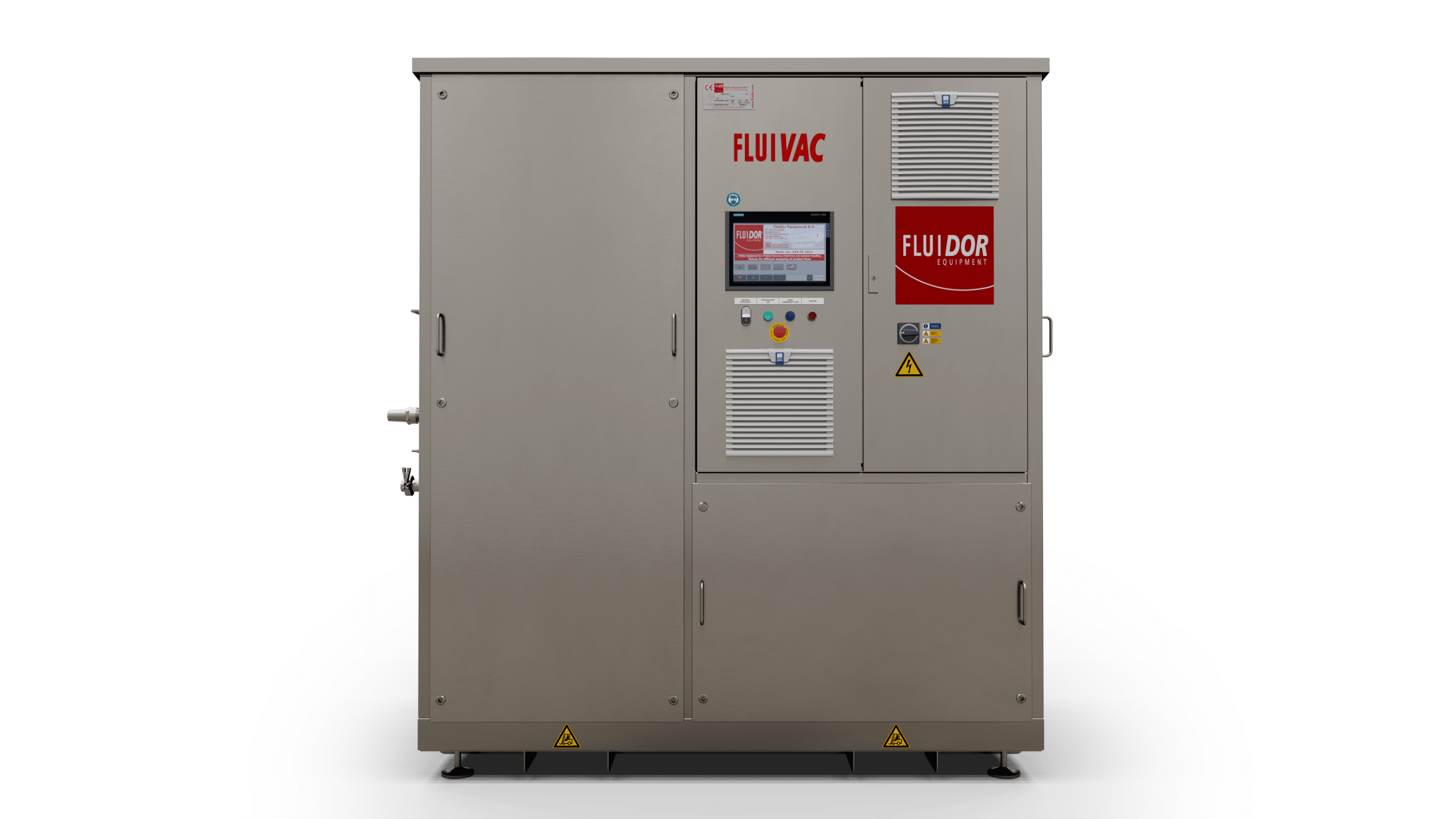

You can obtain several data out of the control system. Please discuss in detail what data you expect, prior to installation of the equipment.

How the Filling line works:

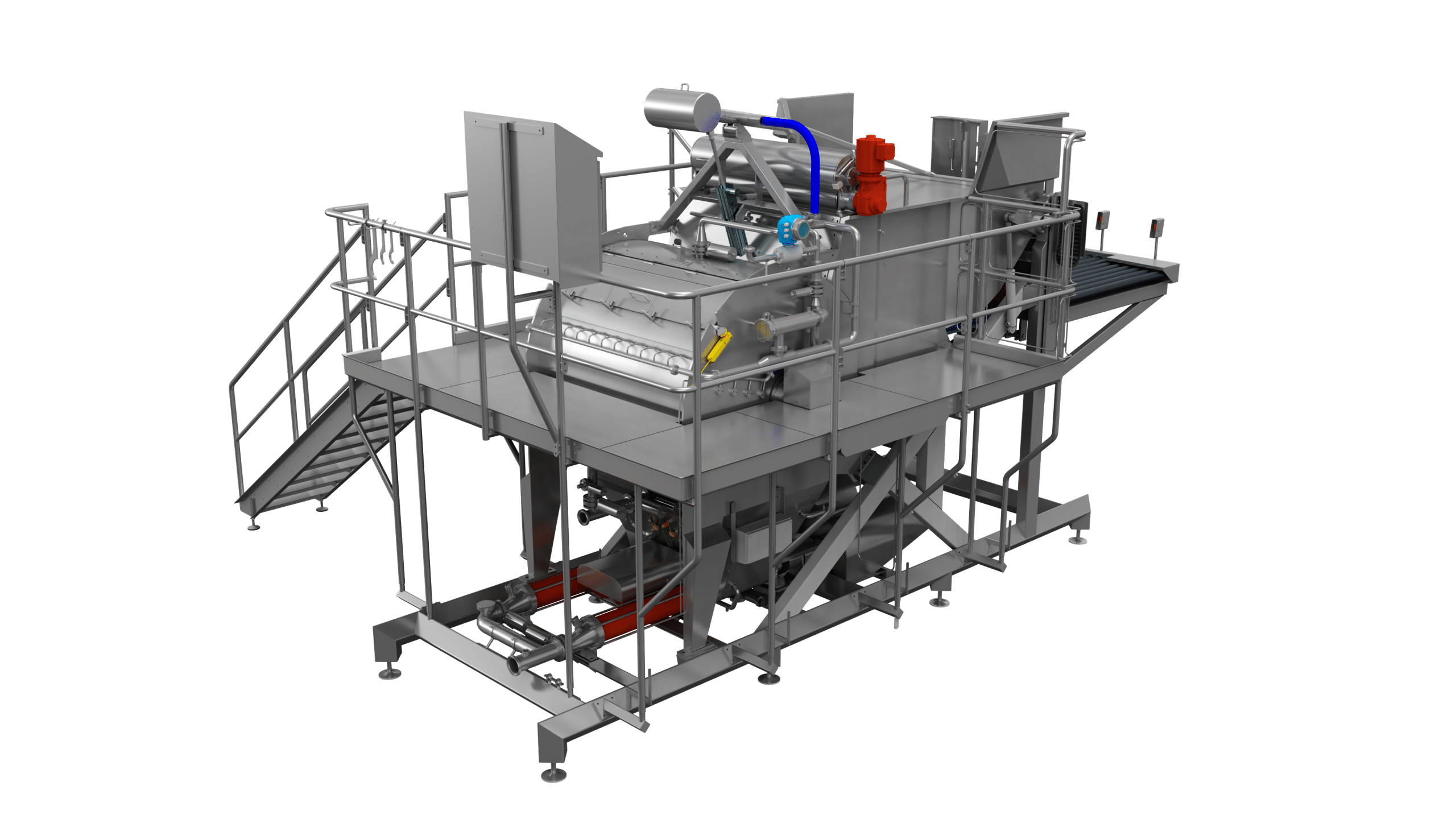

A complete Drum Filling Line consists out of following process steps:

- Station for insertion of plastic bags or liners by means of a Bagblower.

- Drum Filling Station on load cells with Filling Lance.

- Stop position for closing of bags/liners.

- Drum lid press for closing of drum.

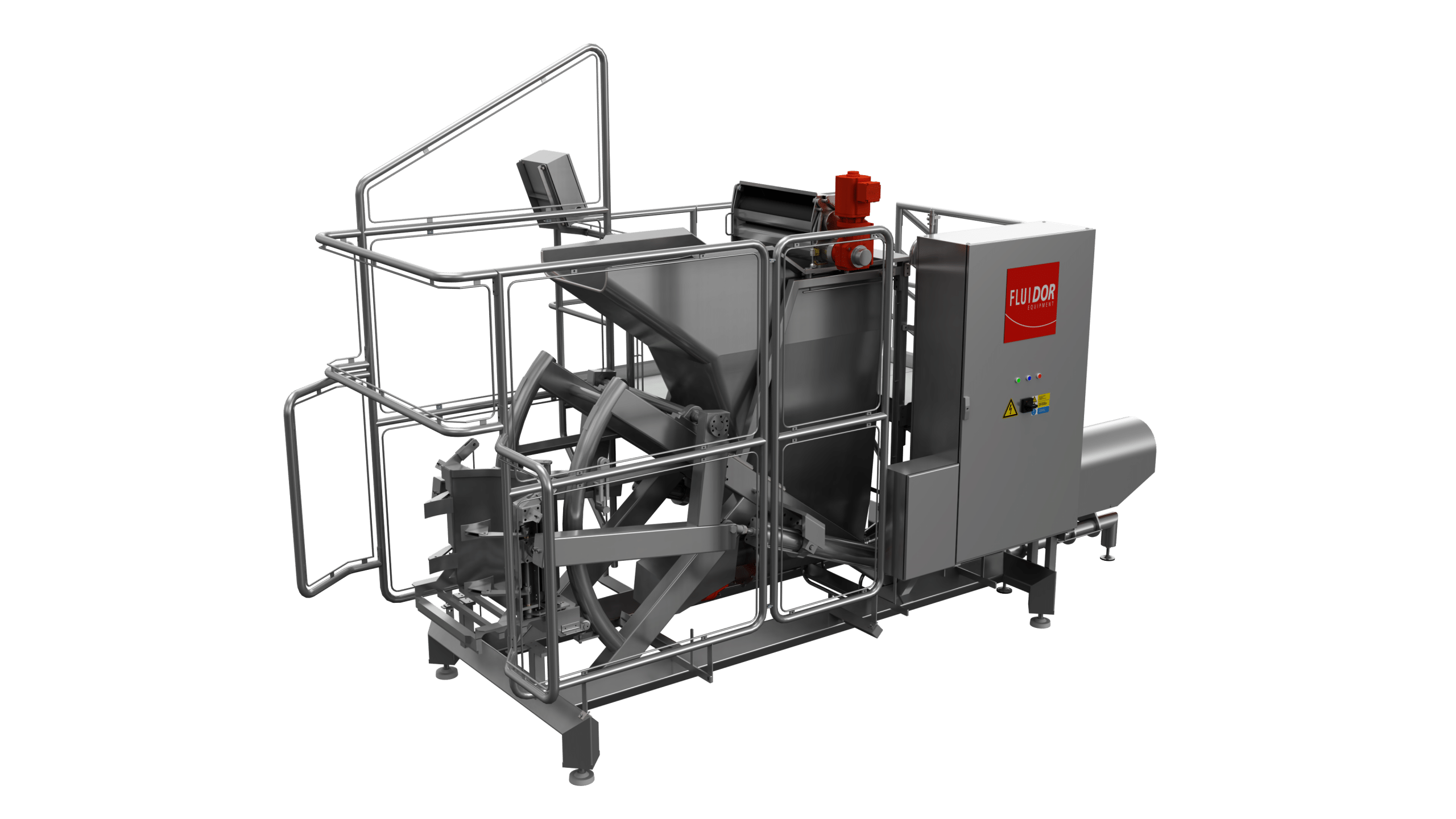

- Pneumatic driven sliding doors to enter/exit a Clean Room.

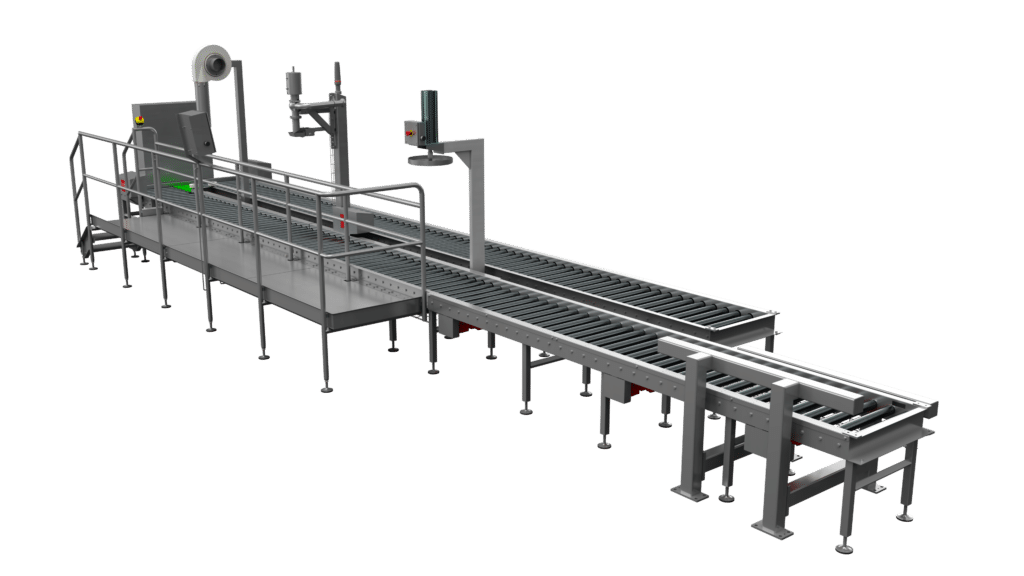

This is how the Filling line works:

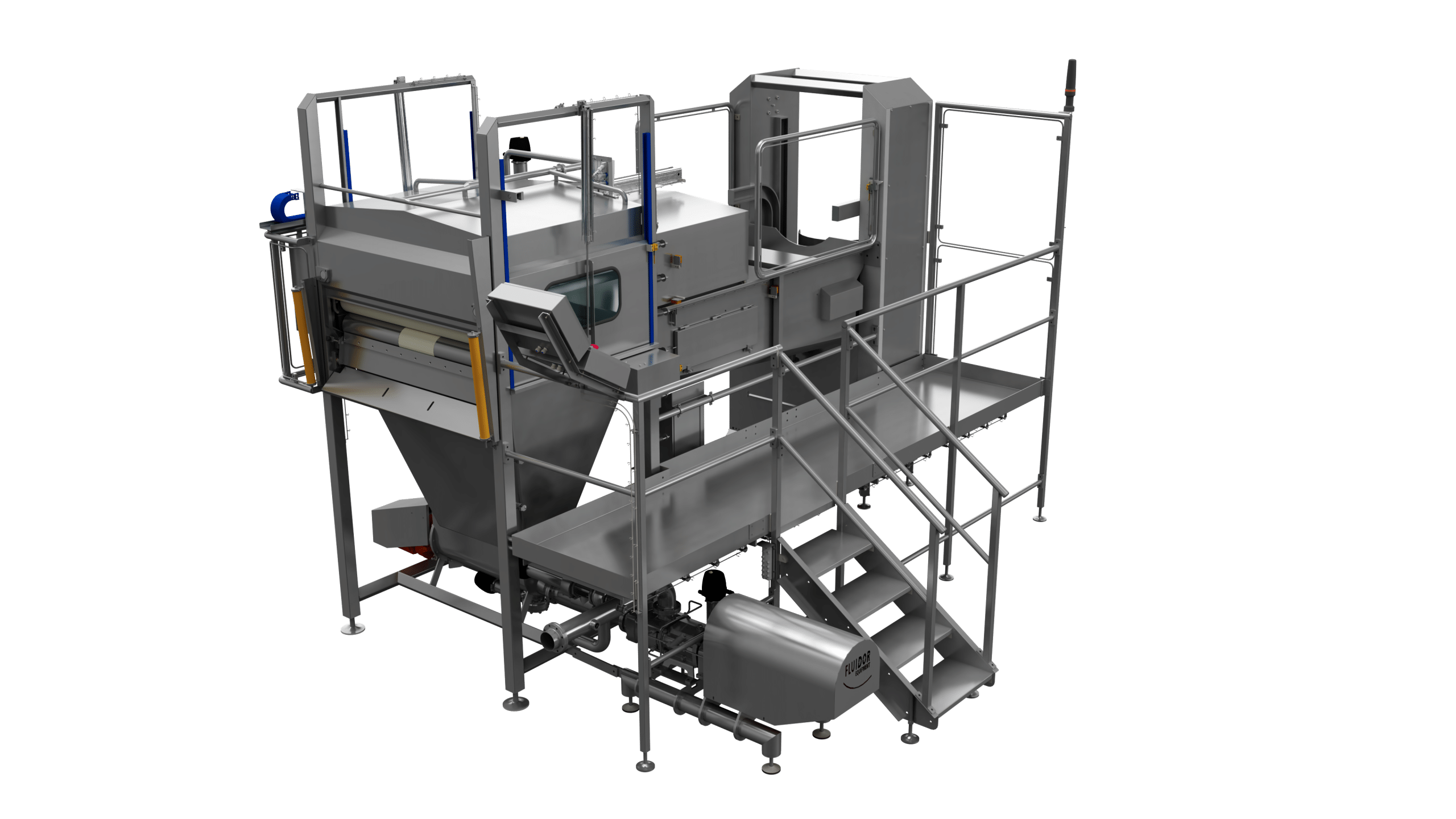

- Full drums leave the Clean Room through a pneumatic driven sliding door.

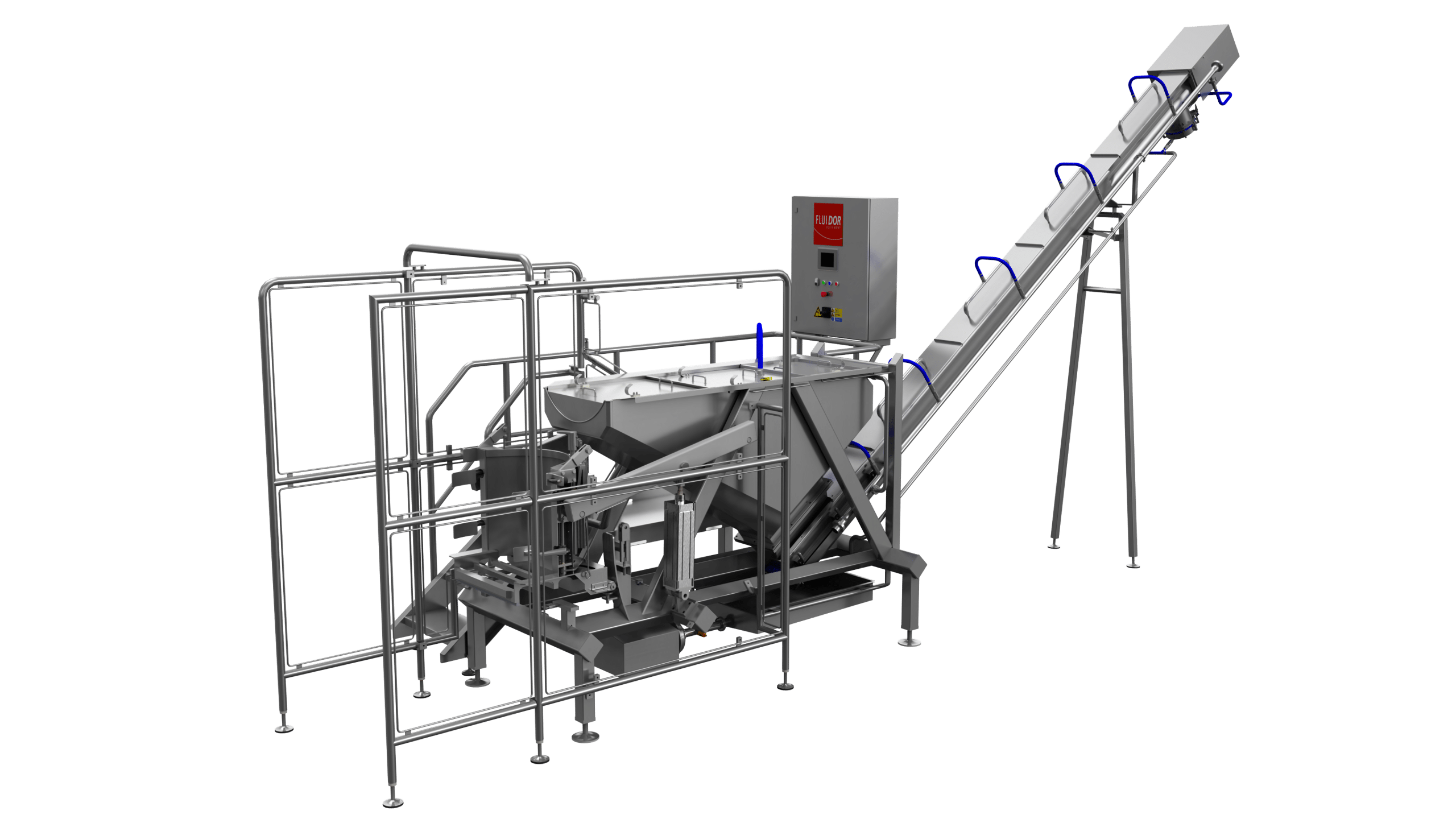

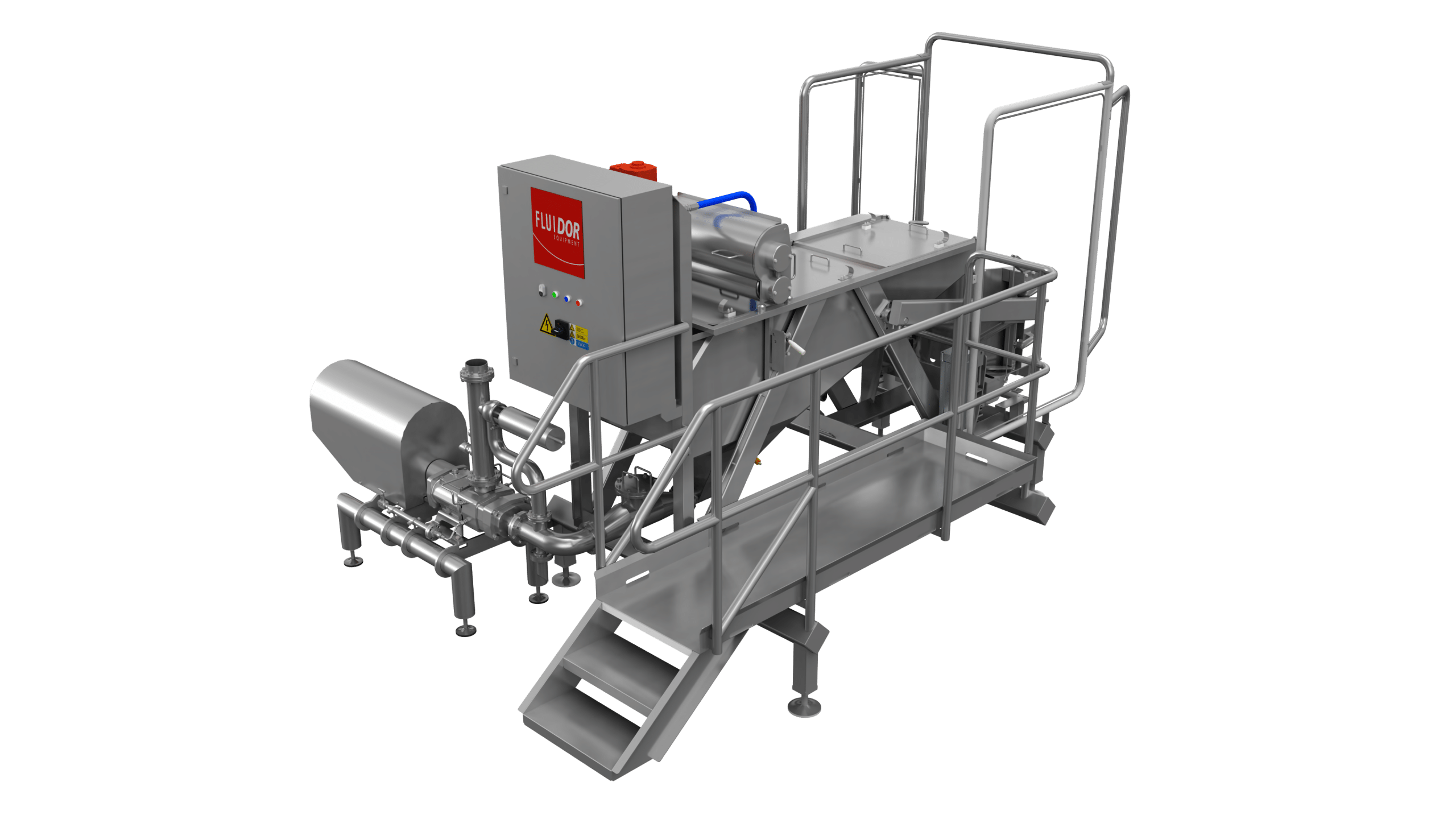

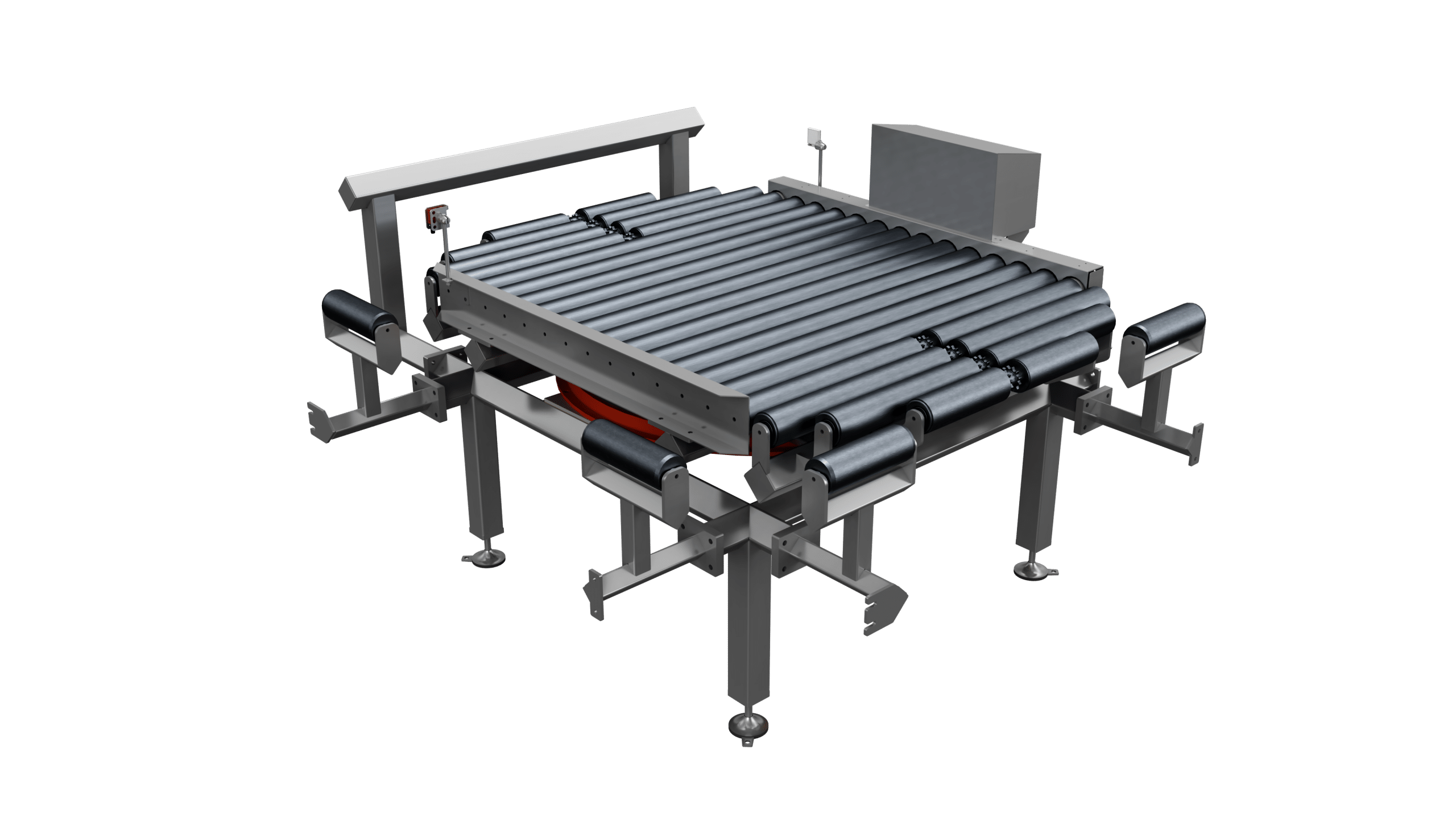

- Empty drums are loaded onto a driven roller conveyor, enter the Clean Room and stop at position for manual insertion of plastic liner(s) by means of a Bagblower. The Bagblower is an electric driven air blower, executed with an air filter for clean air inside bags/liners.

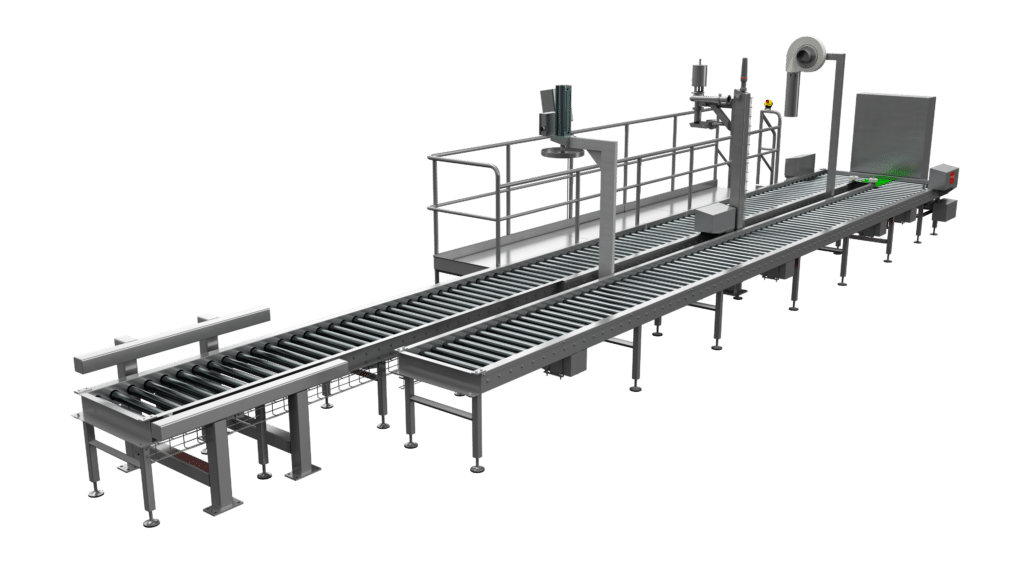

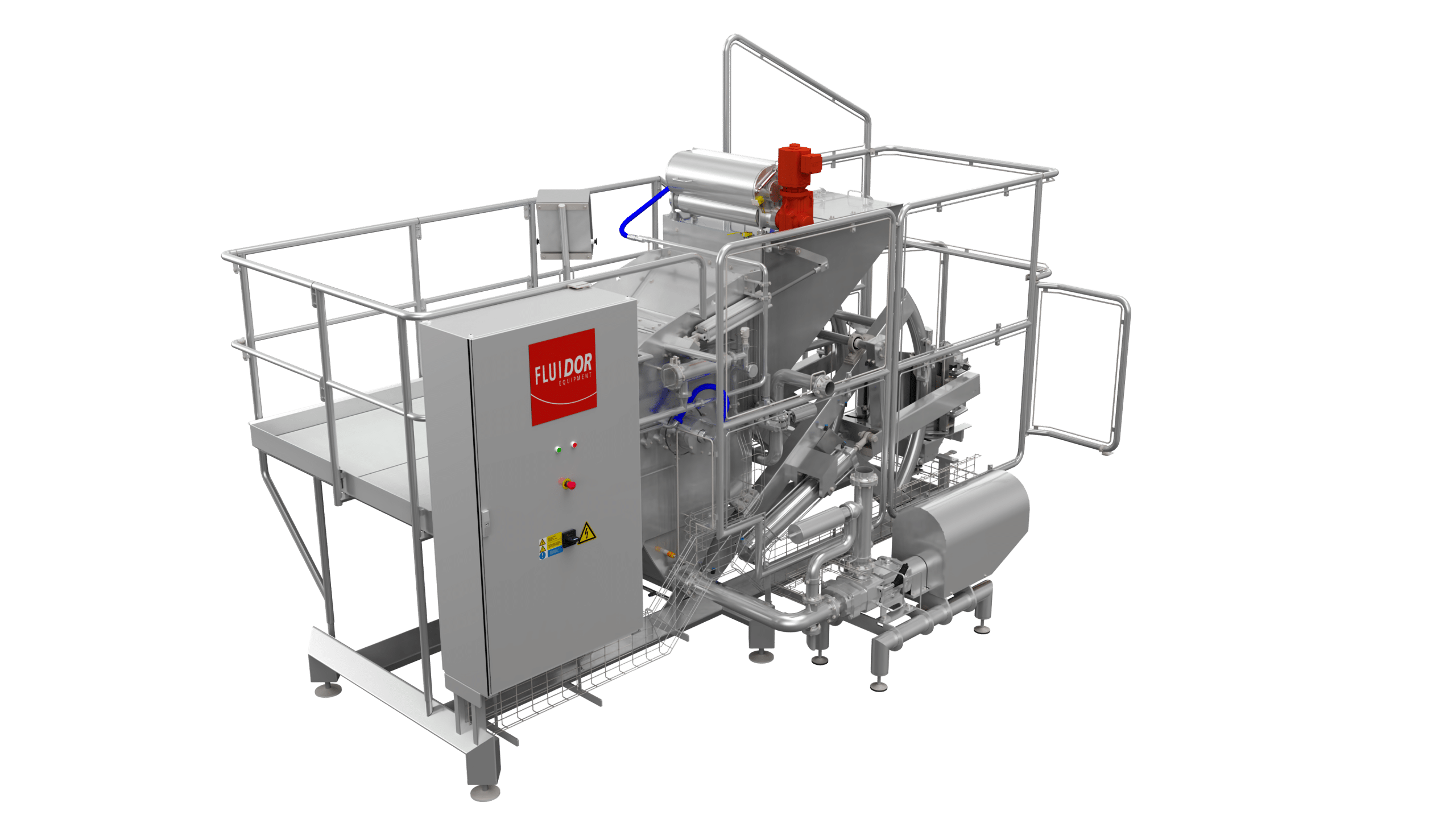

- Drum with liner will be conveyed to the filling position, where the drum is positioned on a roller conveyor section equipped with 4 load cells to control the weight of the product to be loaded.

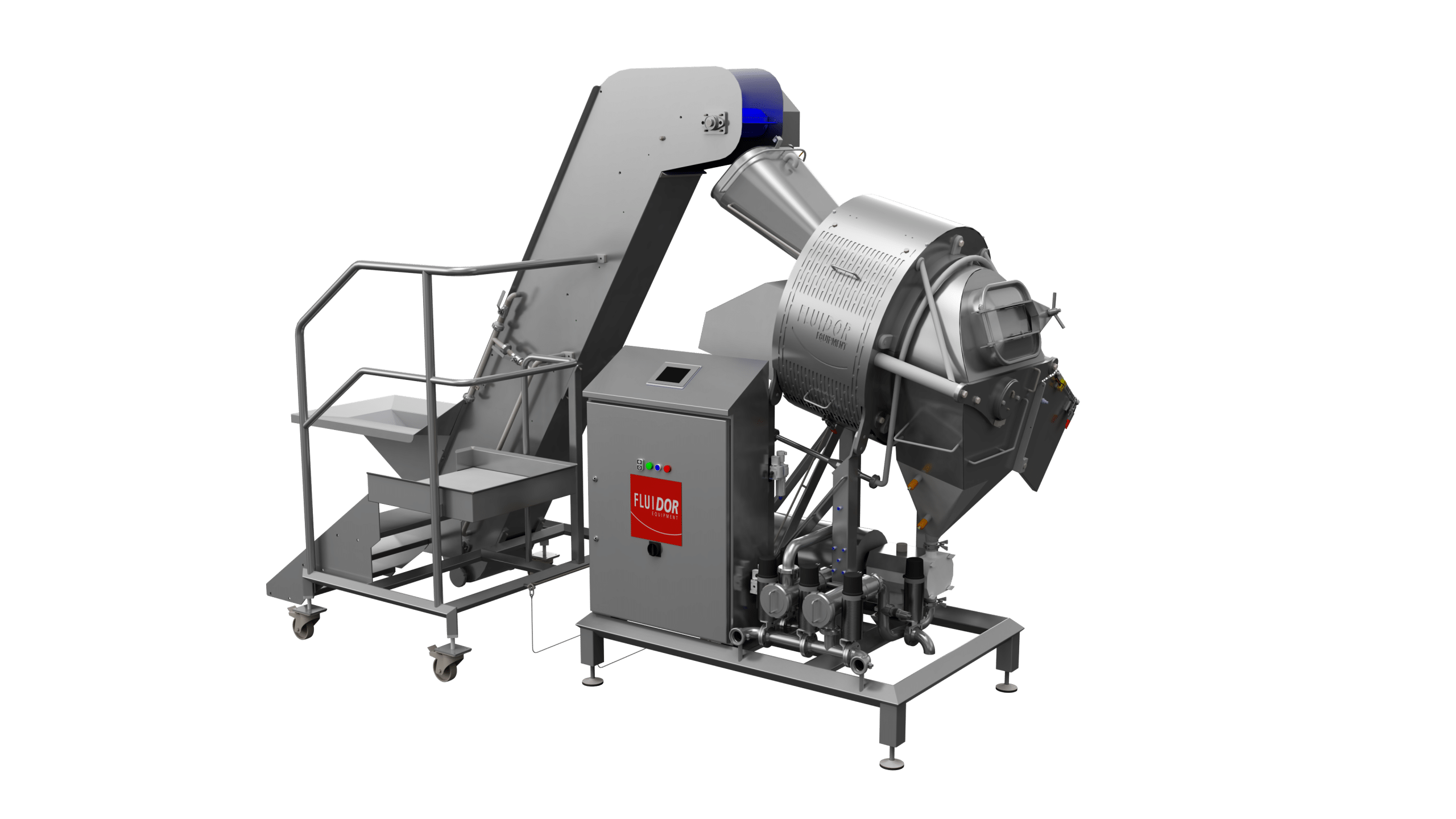

- The Filling Lance lowers by means of a frequency controlled electric motor into the drum and starts loading at full flow. The position of the Filling Lance is automatically controlled by the load cells and frequency drive to prevent foaming of the product. The last part of loading is at low flow to achieve an accuracy of 0,5 kg.

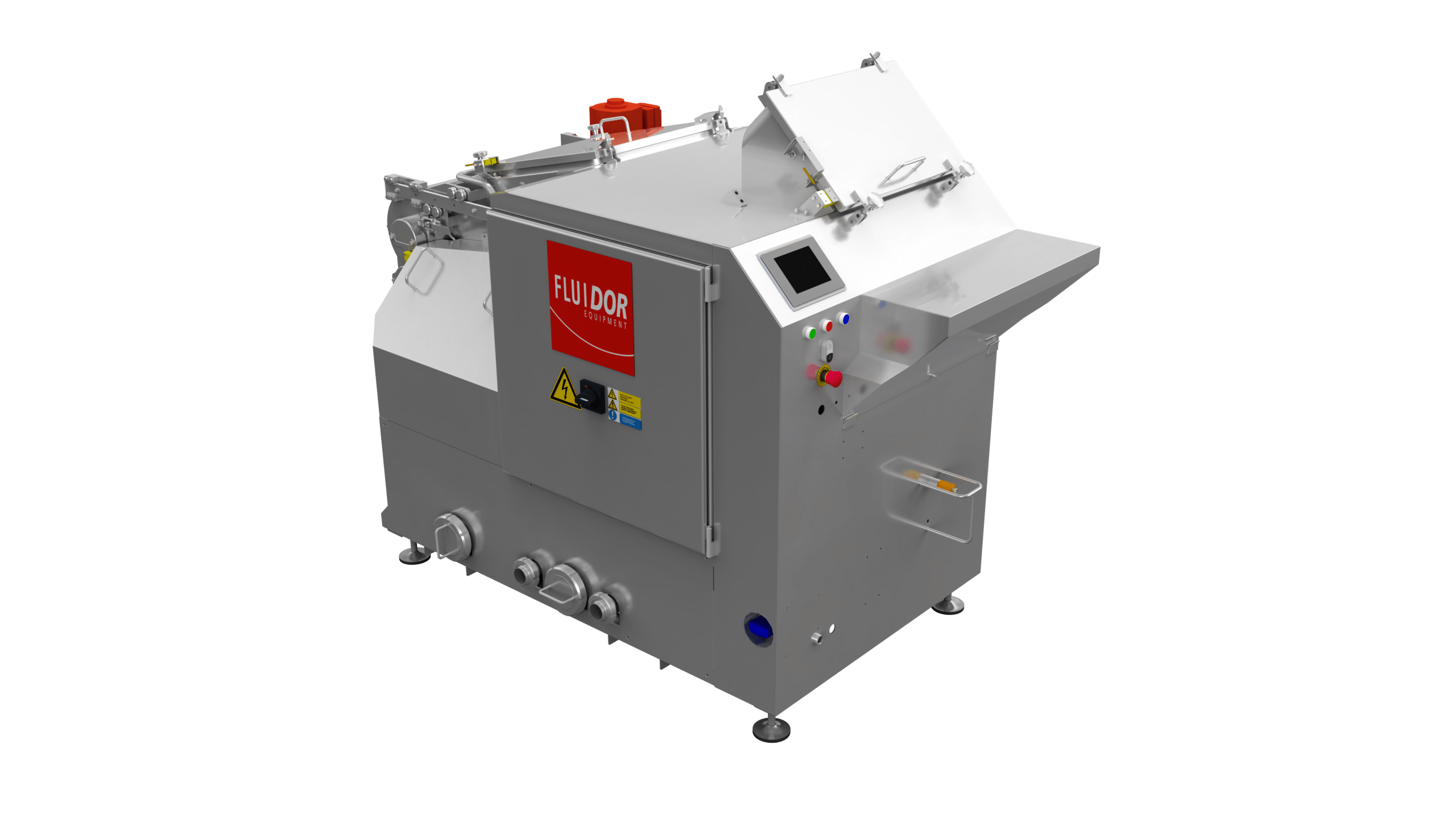

- Drum with product will be conveyed to next stop position for manual closing of liners, finally the drum will stop at the Drum Closing Station, where an operator positions the drum lid properly by means of a pneumatic press and secures the clamping ring by a pneumatic nut spanner.

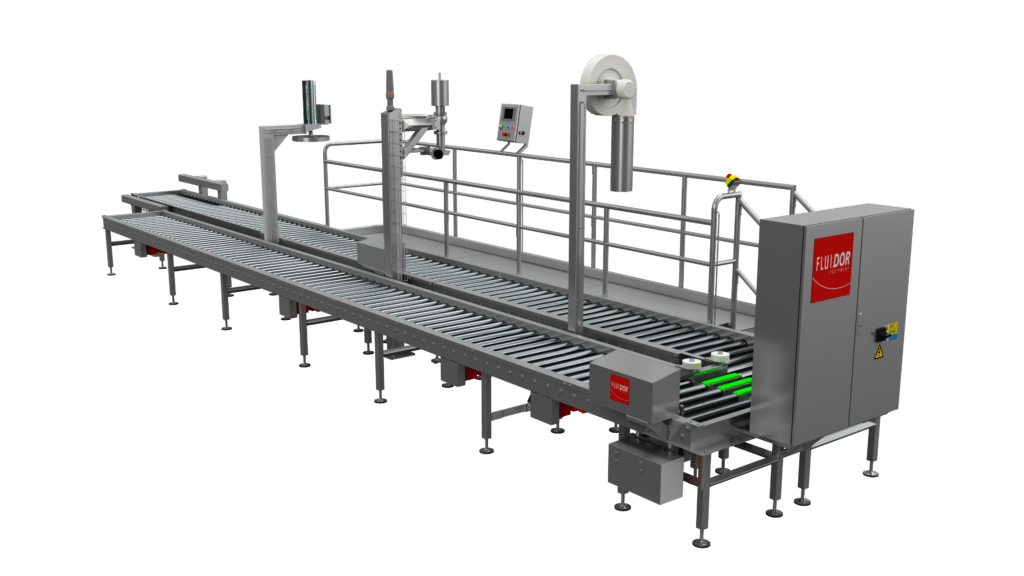

The filling line for drums guarantees accurate filling to exact specifications. So you can maintain your product quality and consistency and reduce errors in production.

The filling line automates the filling process, improves throughput and reduces labour costs. Enhance your operational efficiency and productivity.

The filling line for drums handles various drum sizes and types. Adapt it to your different production needs.