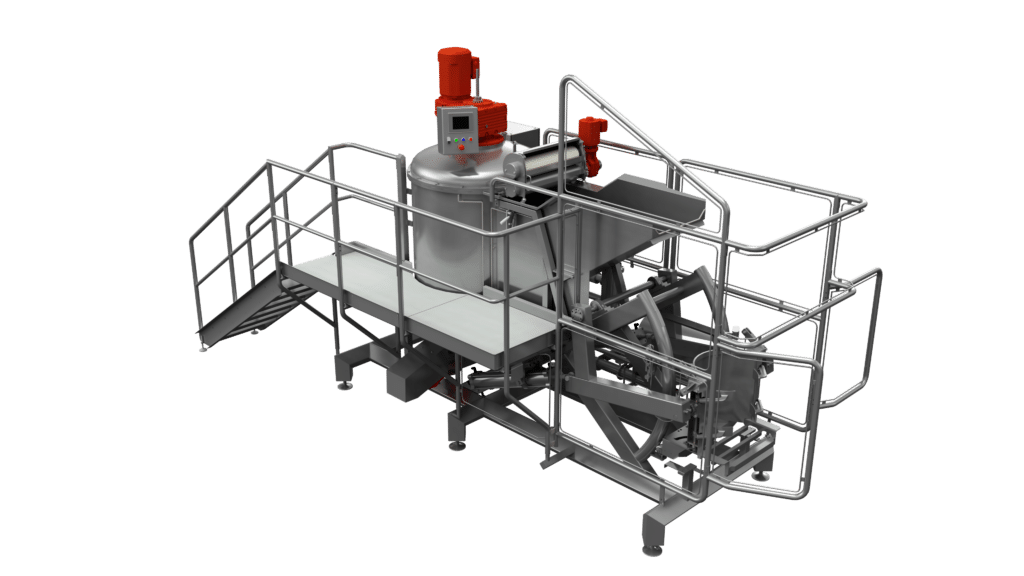

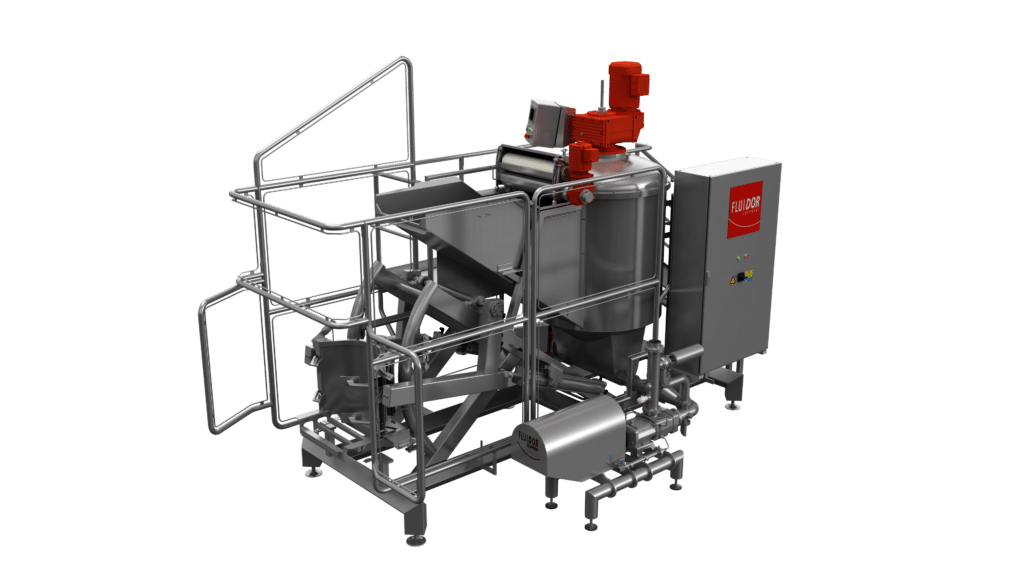

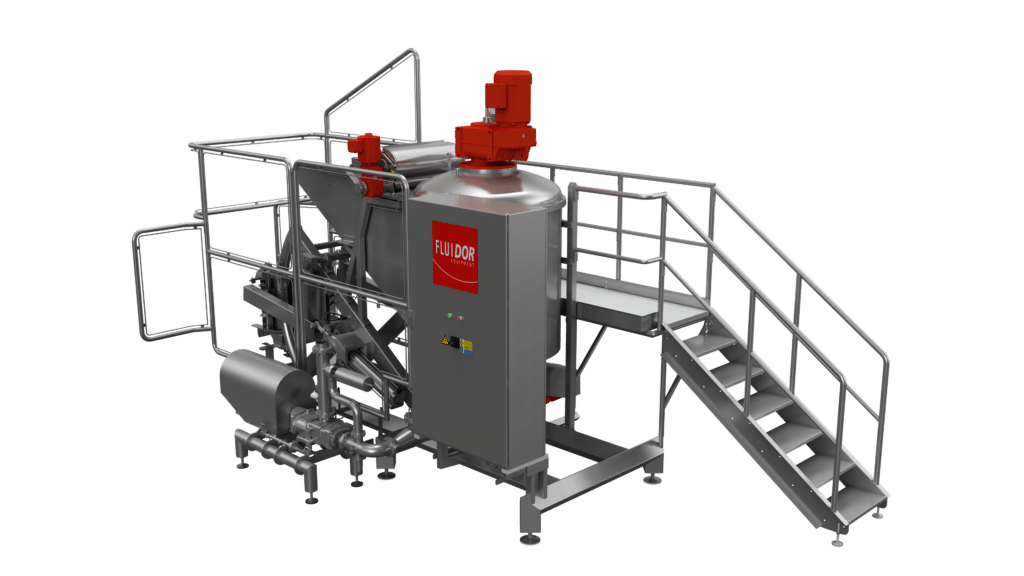

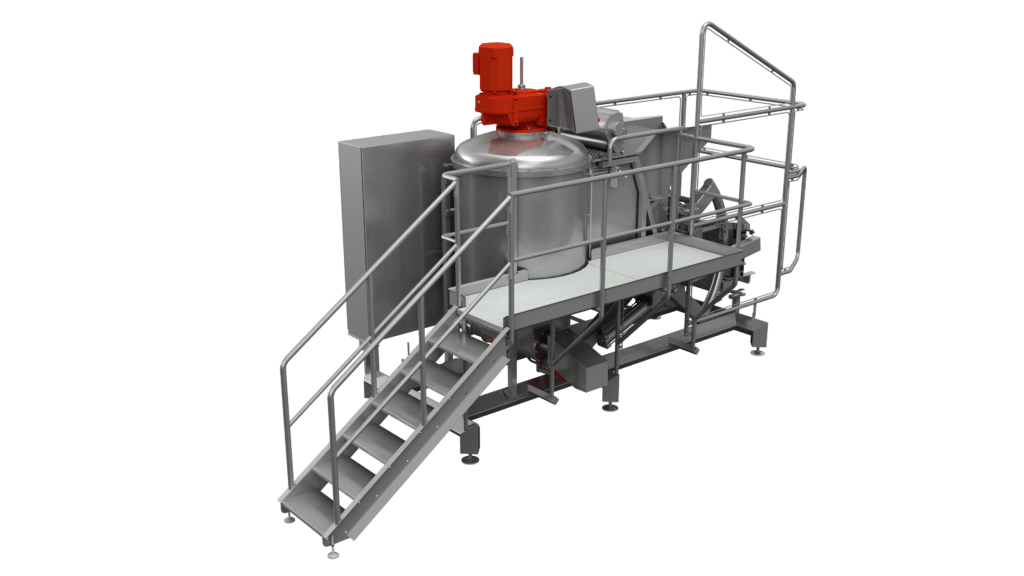

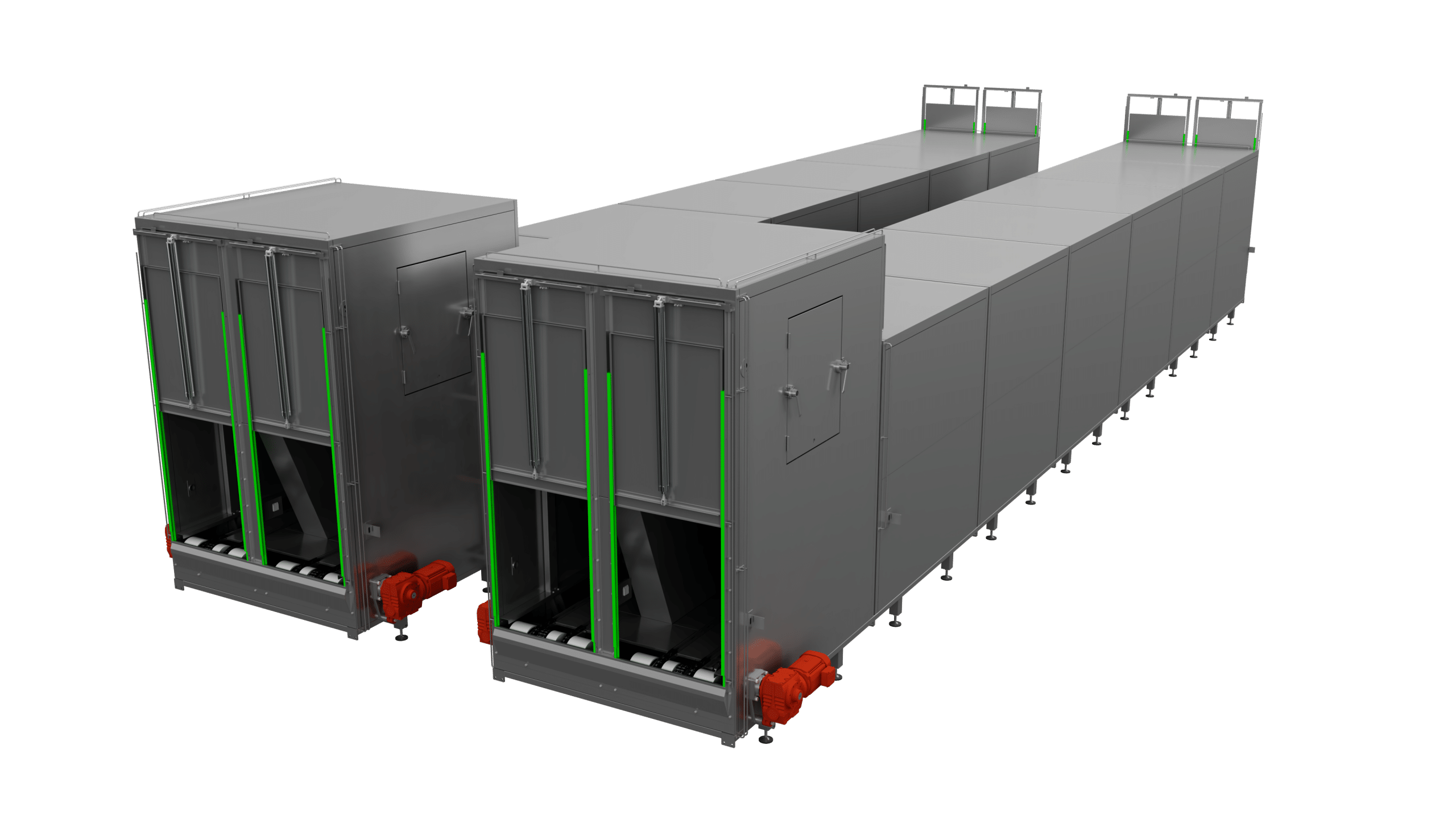

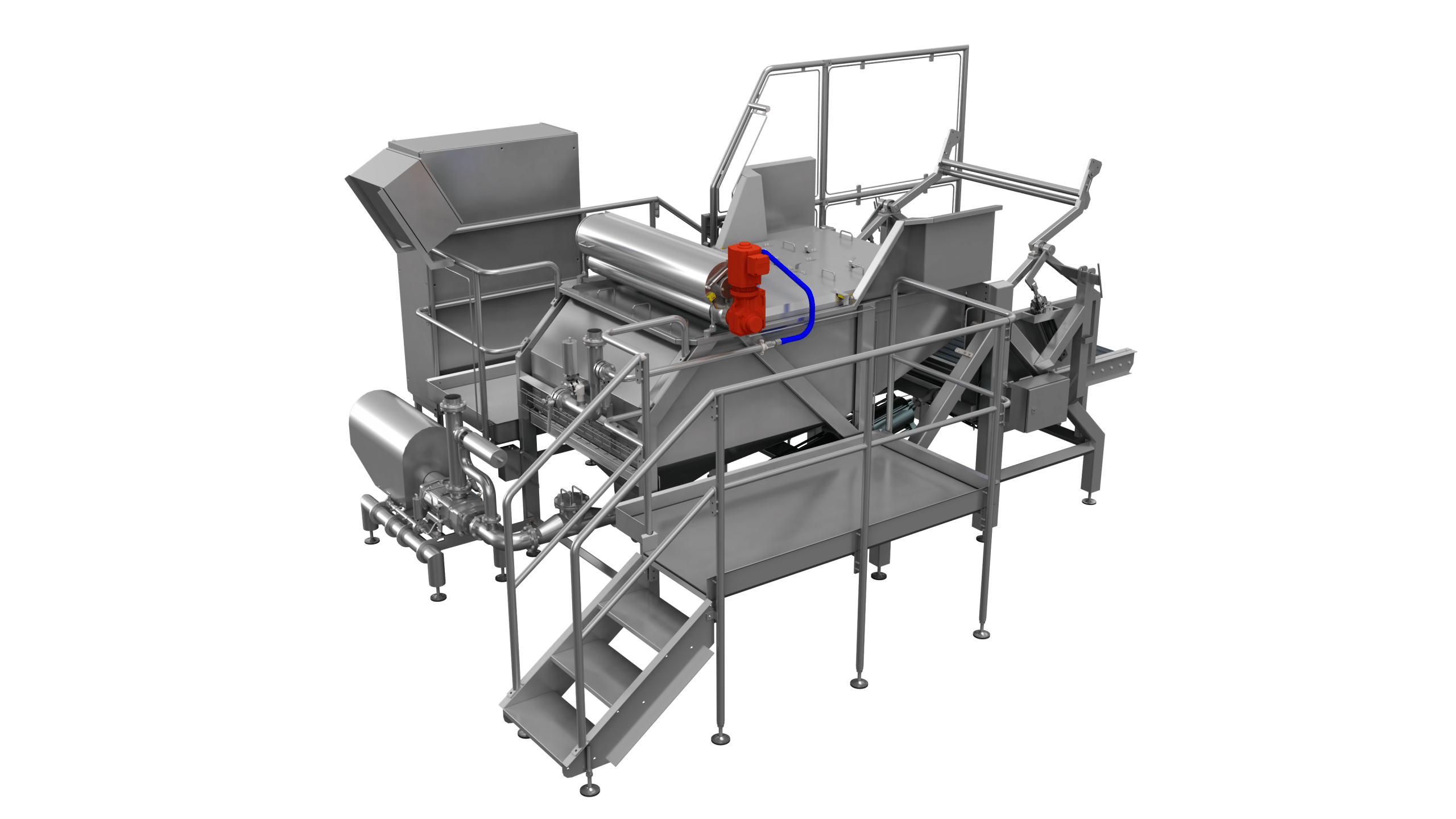

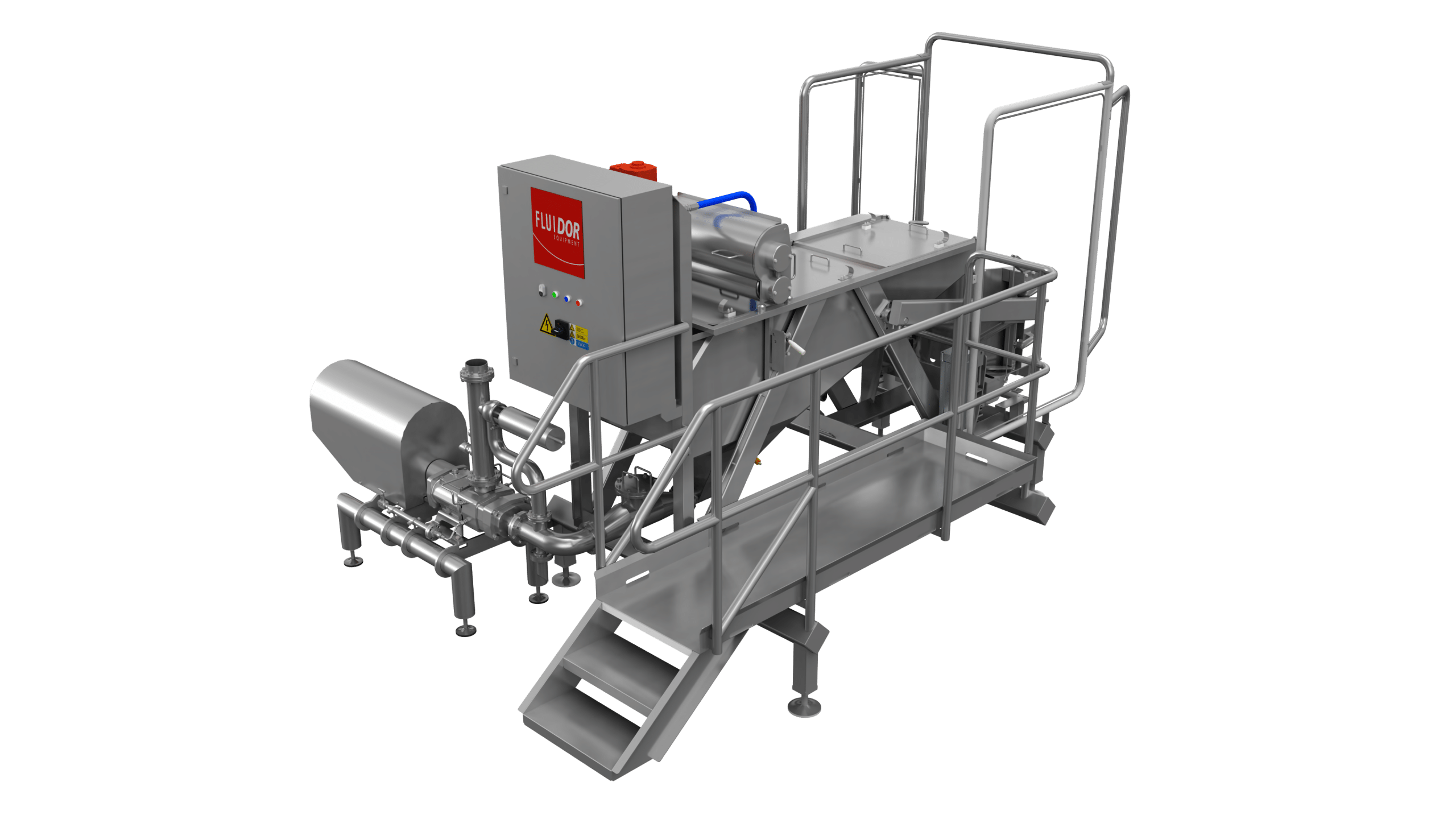

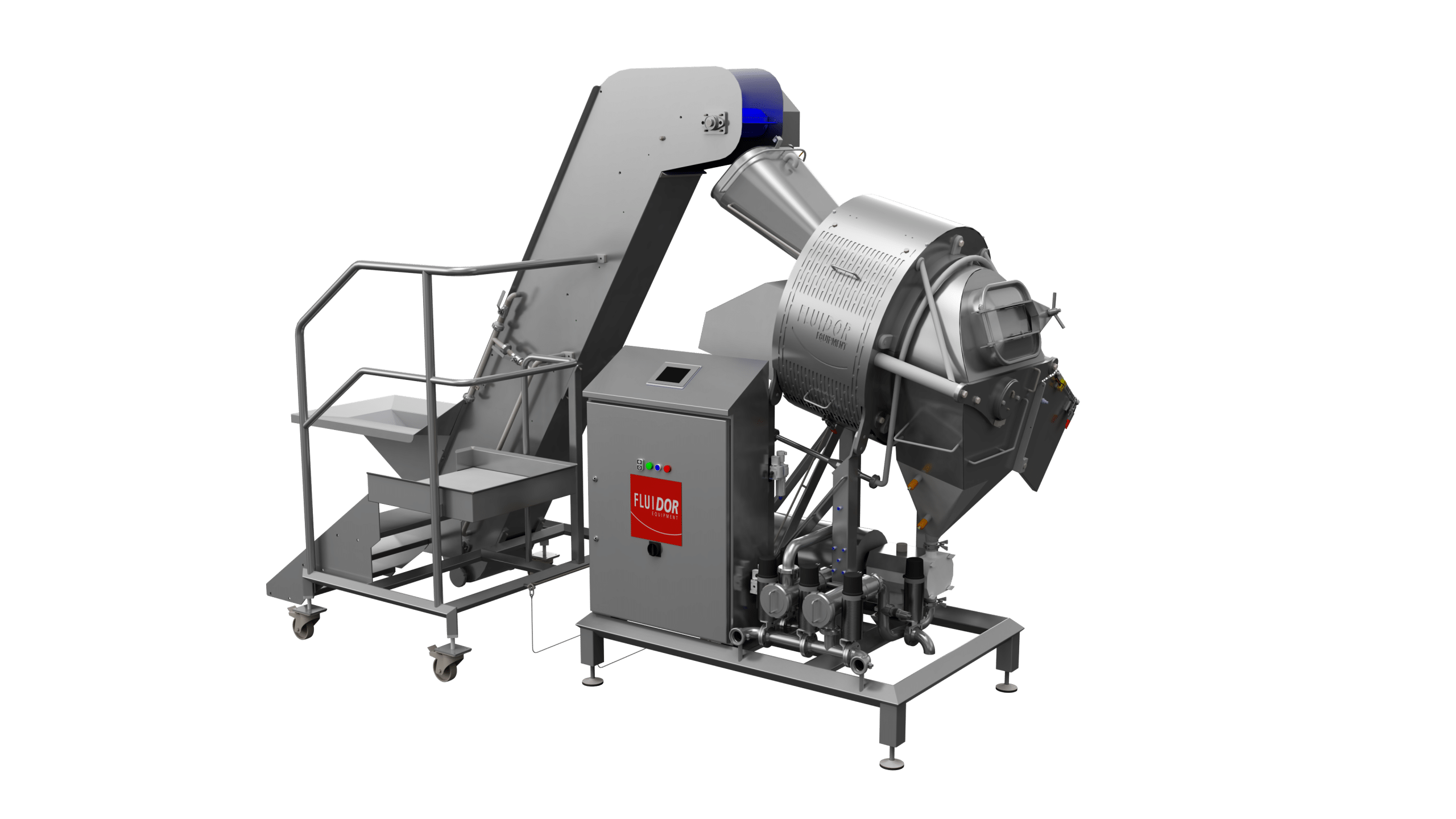

The Drum Dumper Crusher (DPRCS)

With the Drum Dumper Crusher (DPRCS), you can efficiently empty open top drums containing soft frozen liquid products.

Empty drums with soft frozen liquid products

Does your industry benefit from emptying drums with soft frozen product and chopping it into smaller pieces?

The Drum Dumper Crusher (DPRCS) is designed for an efficient emptying of 200 litre open top drums containing liquid products like soft frozen fruit juices, fruit juice concentrates (up to 70˚ brix) and honey with a maximum viscosity of 20.000 cP.

Depending on the infeed and your product, it can handle up to 60 drums per hour.

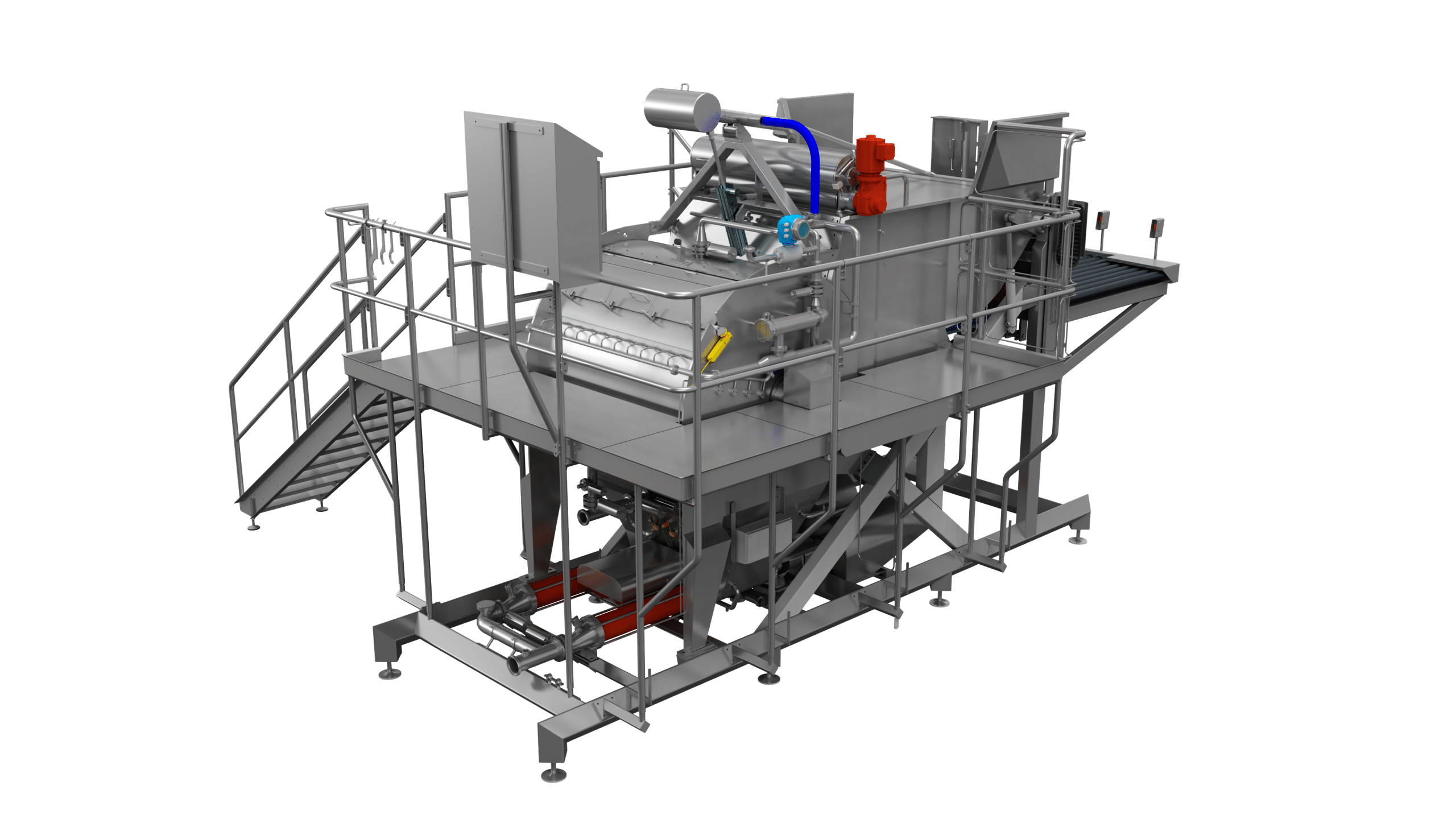

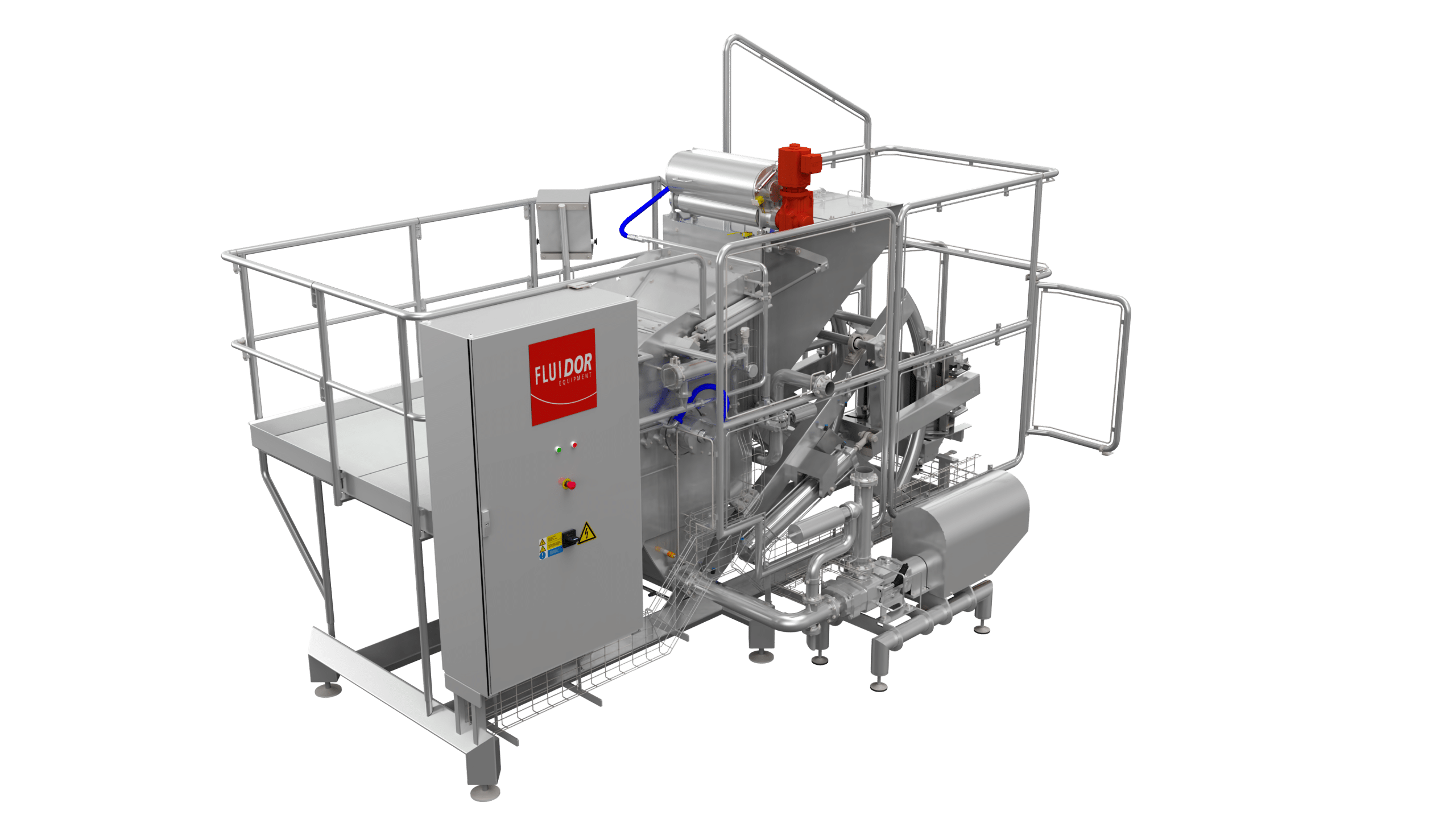

How the DPRCS works:

- After production, the CIP covers can be placed and the DPRCS can be integrated into your CIP process. A complete set of nozzles cleans the inside of the hopper section, according to the set cleaning program.

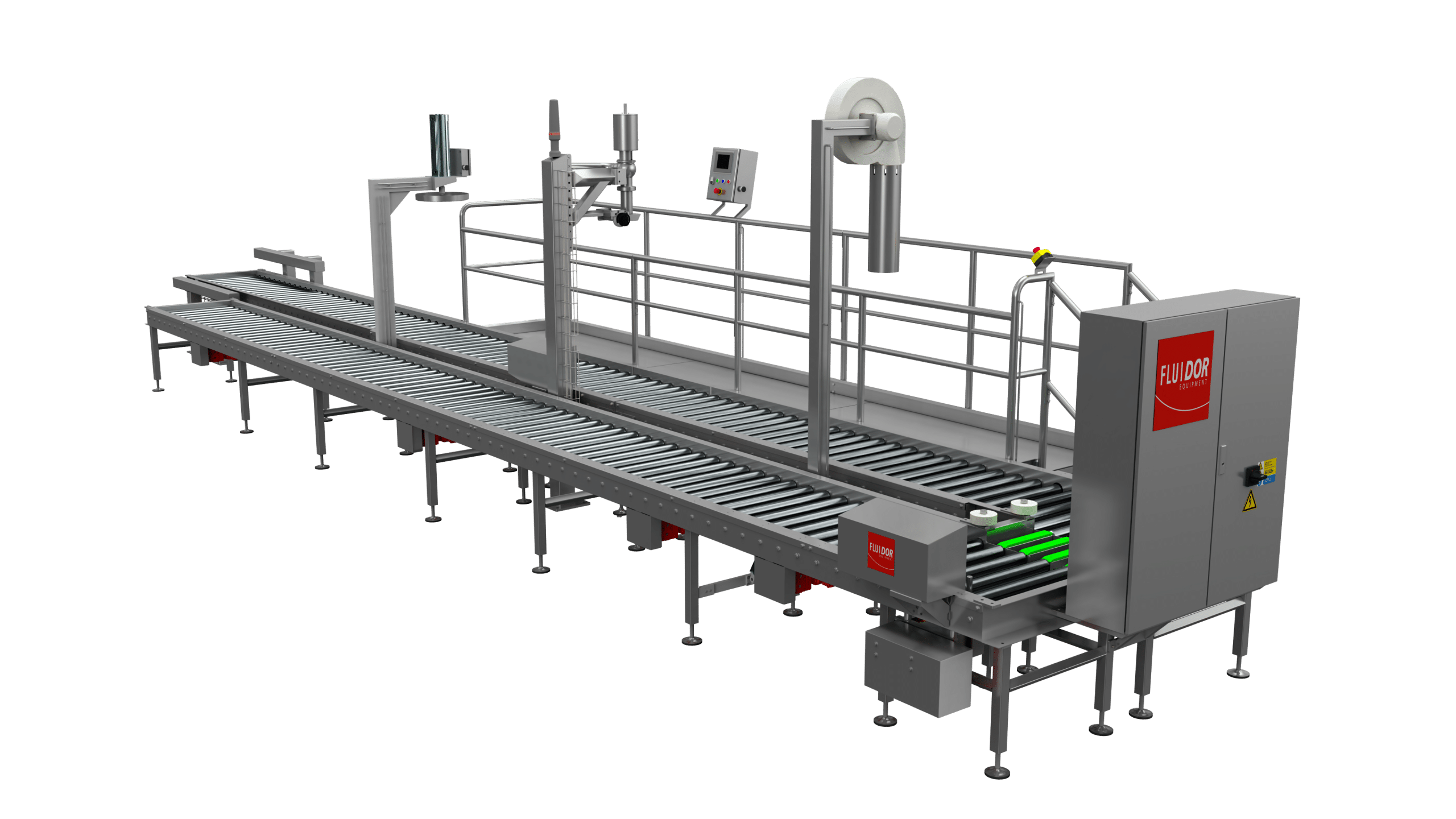

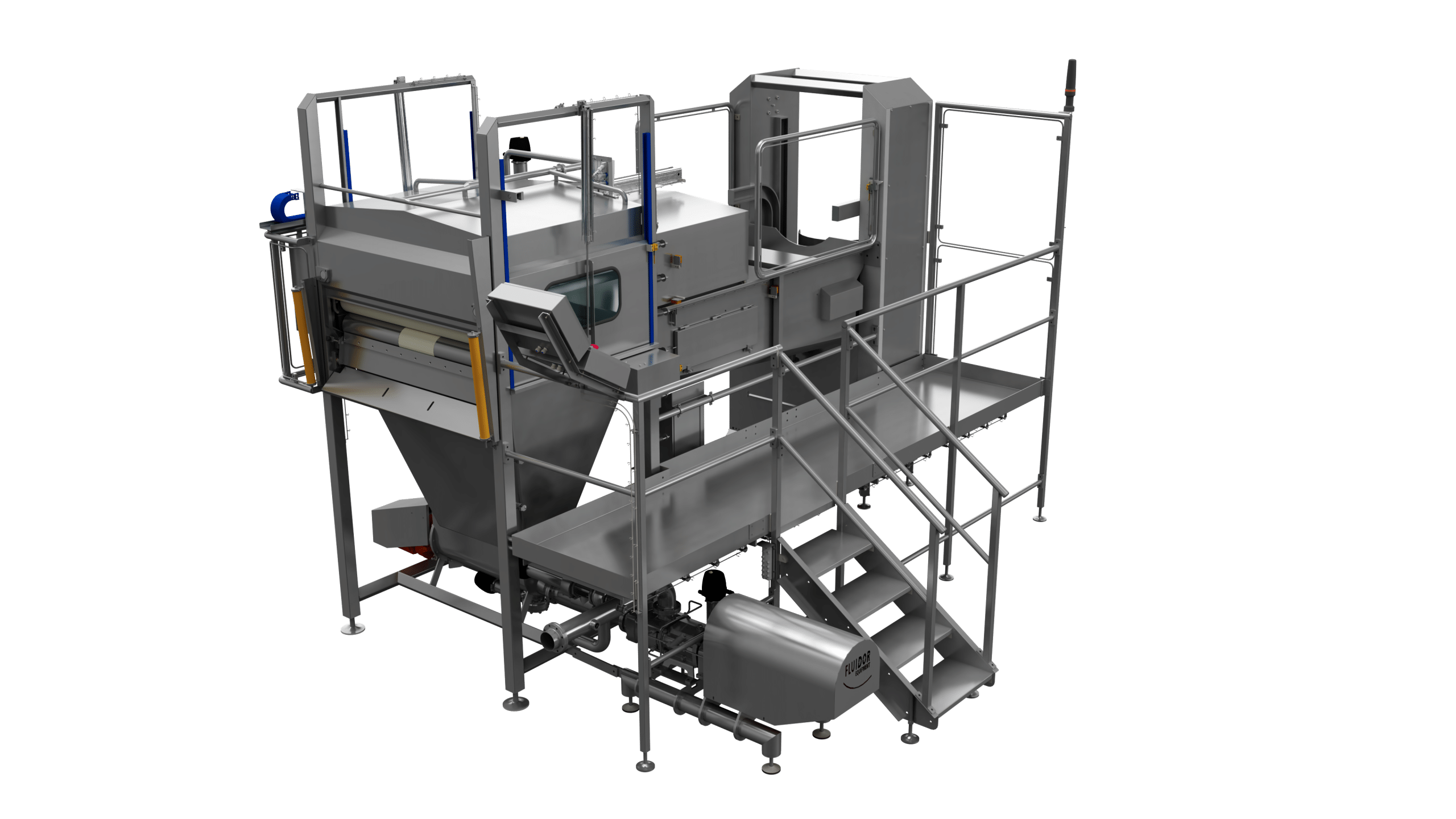

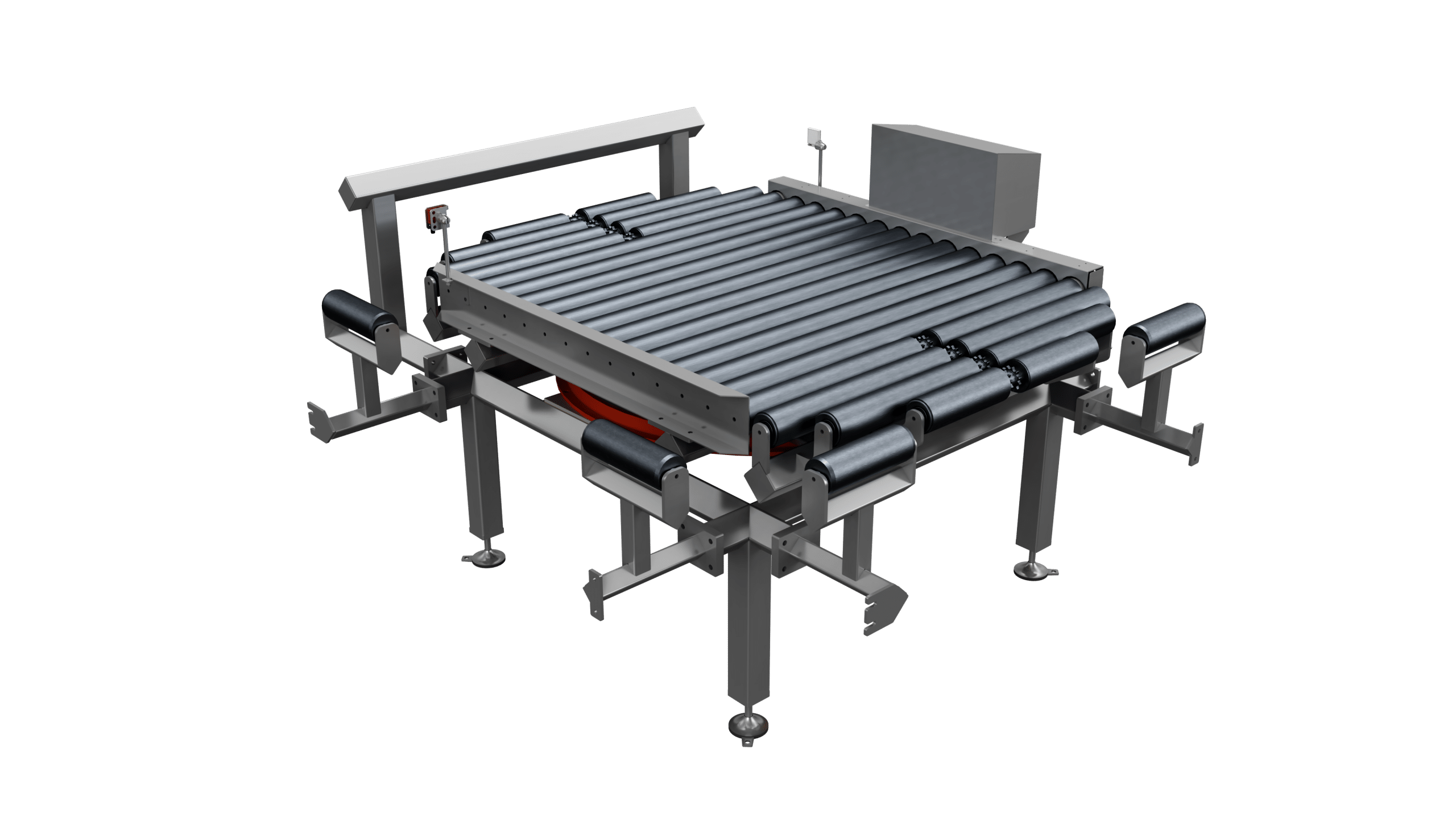

- The drums are placed on the roller conveyor section, where the lid will be removed and liner(s) will be opened.

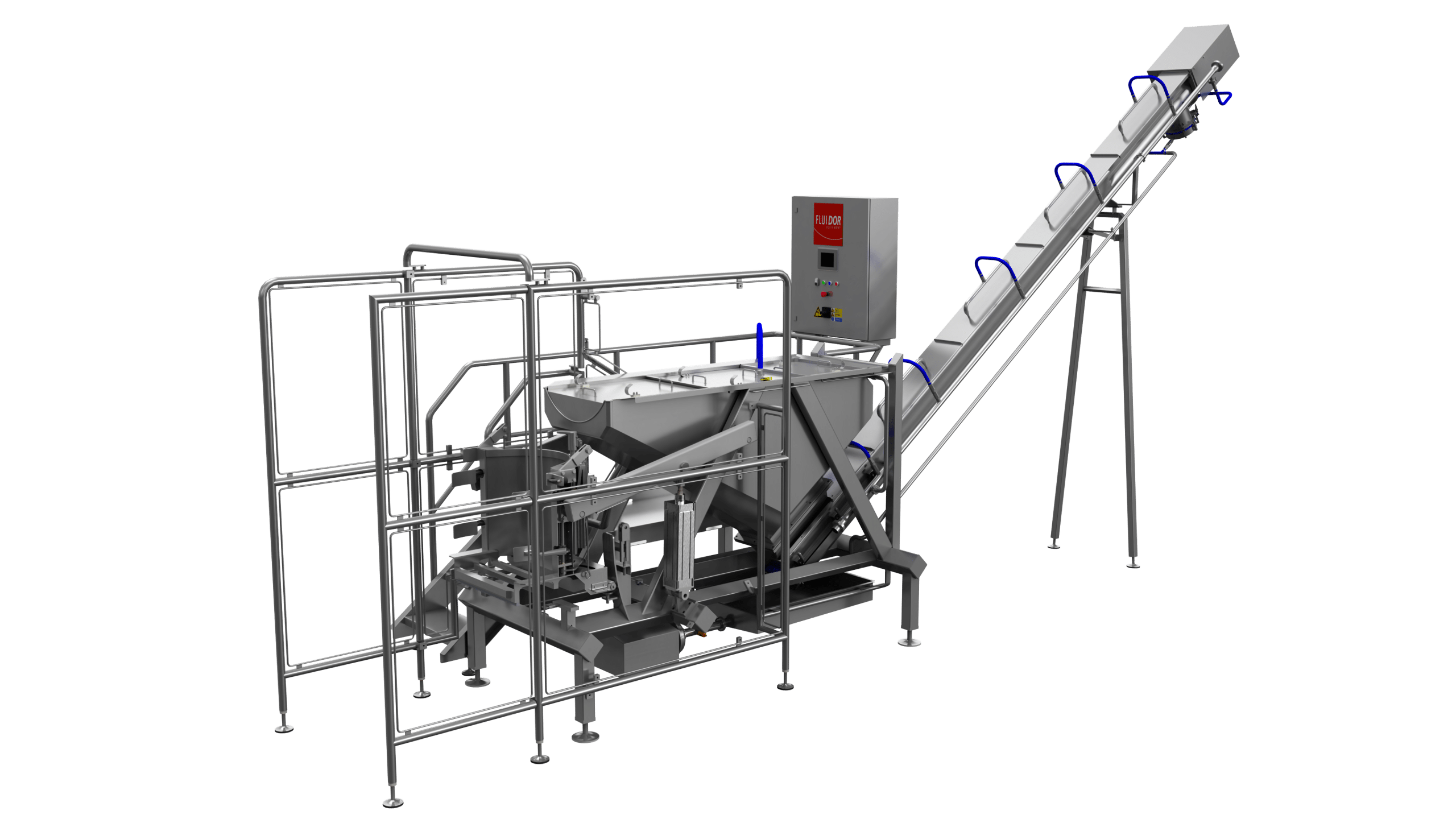

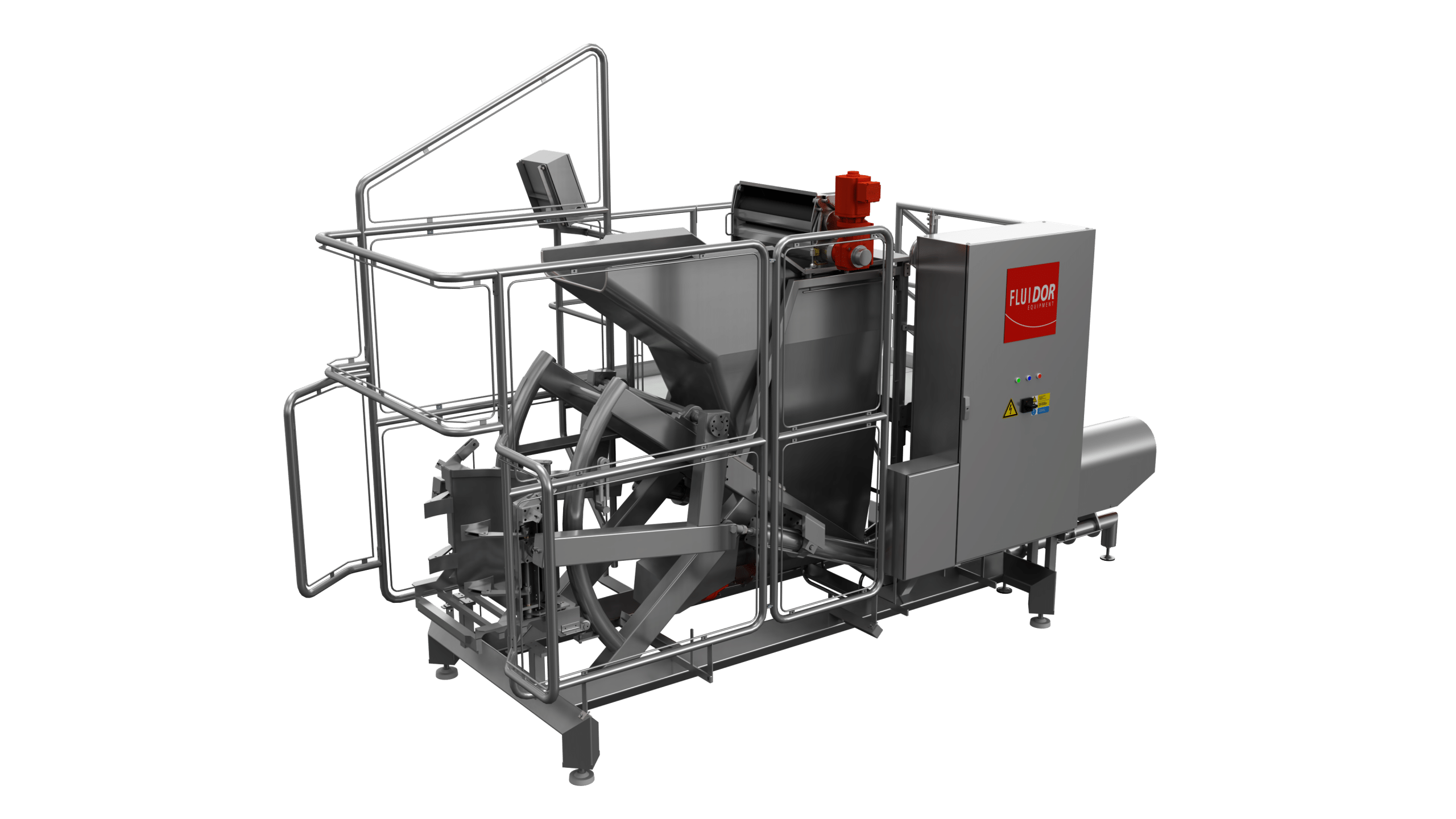

- The drum is lifted and tipped pneumatically, the product falls into the collecting hopper and is stopped by a grid.

- The bag will empty itself partly. The operator brings the bottom part of the bag into the squeezer and the remaining product is pressed out.

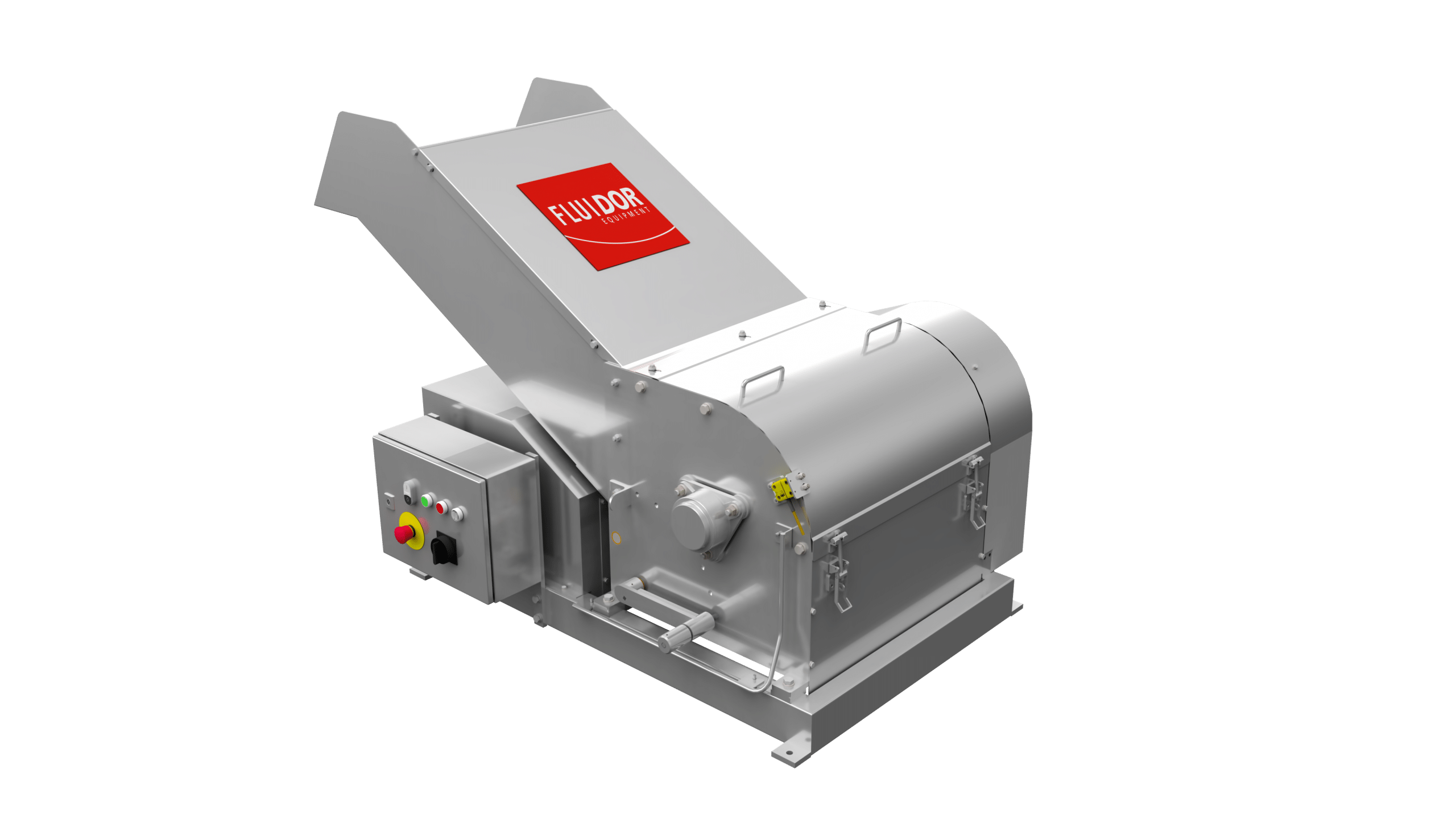

- The product flows into the hopper, where the vertical chopper takes care of an efficient chopping of soft frozen product.

- Finally, the product is discharged by a screw conveyor and twin screw pump.

The DPRCS empties and processes drums efficiently and helps increase production speed and product recovery.

The DPRCS automates pneumatic lifting and tipping to reduce manual handling. It is food and operator safe and integrates with CIP processes.

The DPRCS is suitable for various liquid products and integrates with CIP systems, enhancing operational efficiency and product quality.