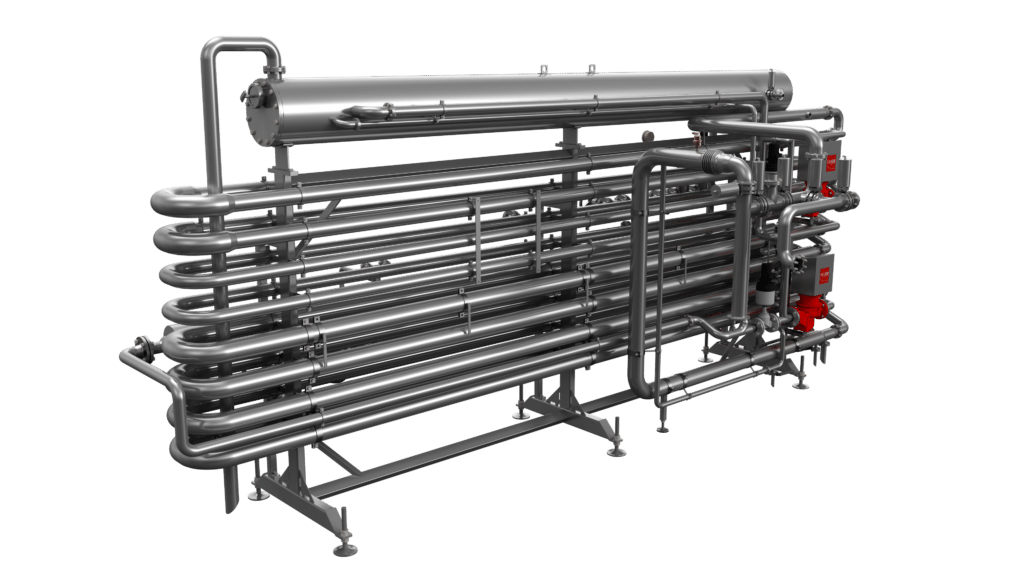

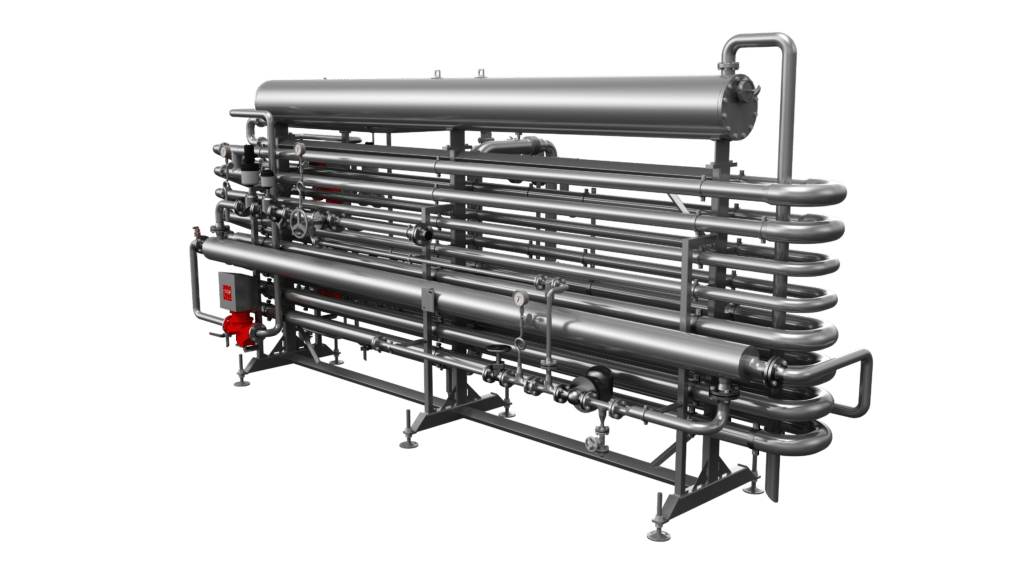

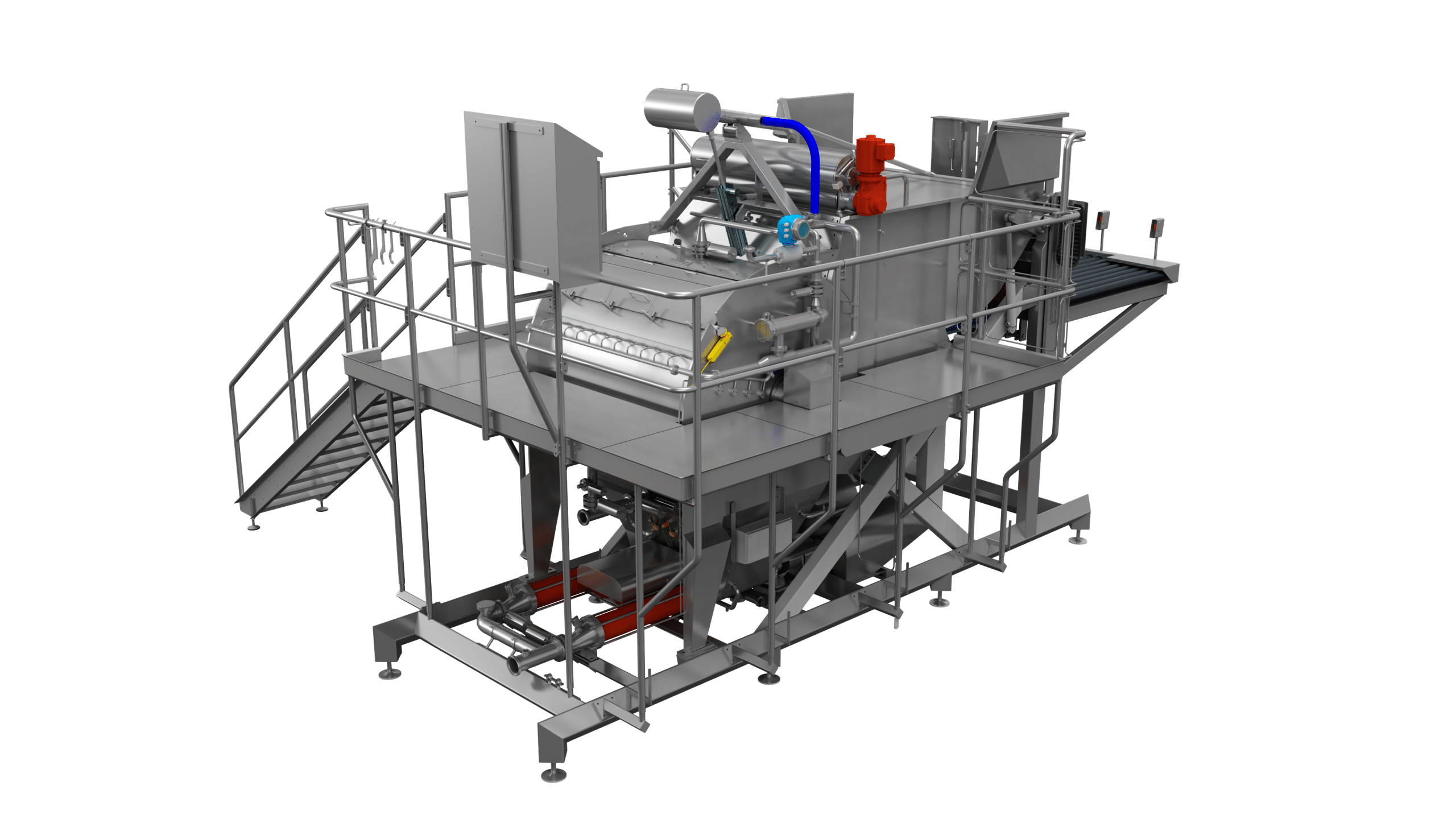

The Crushed Ice-Melter (CIM)

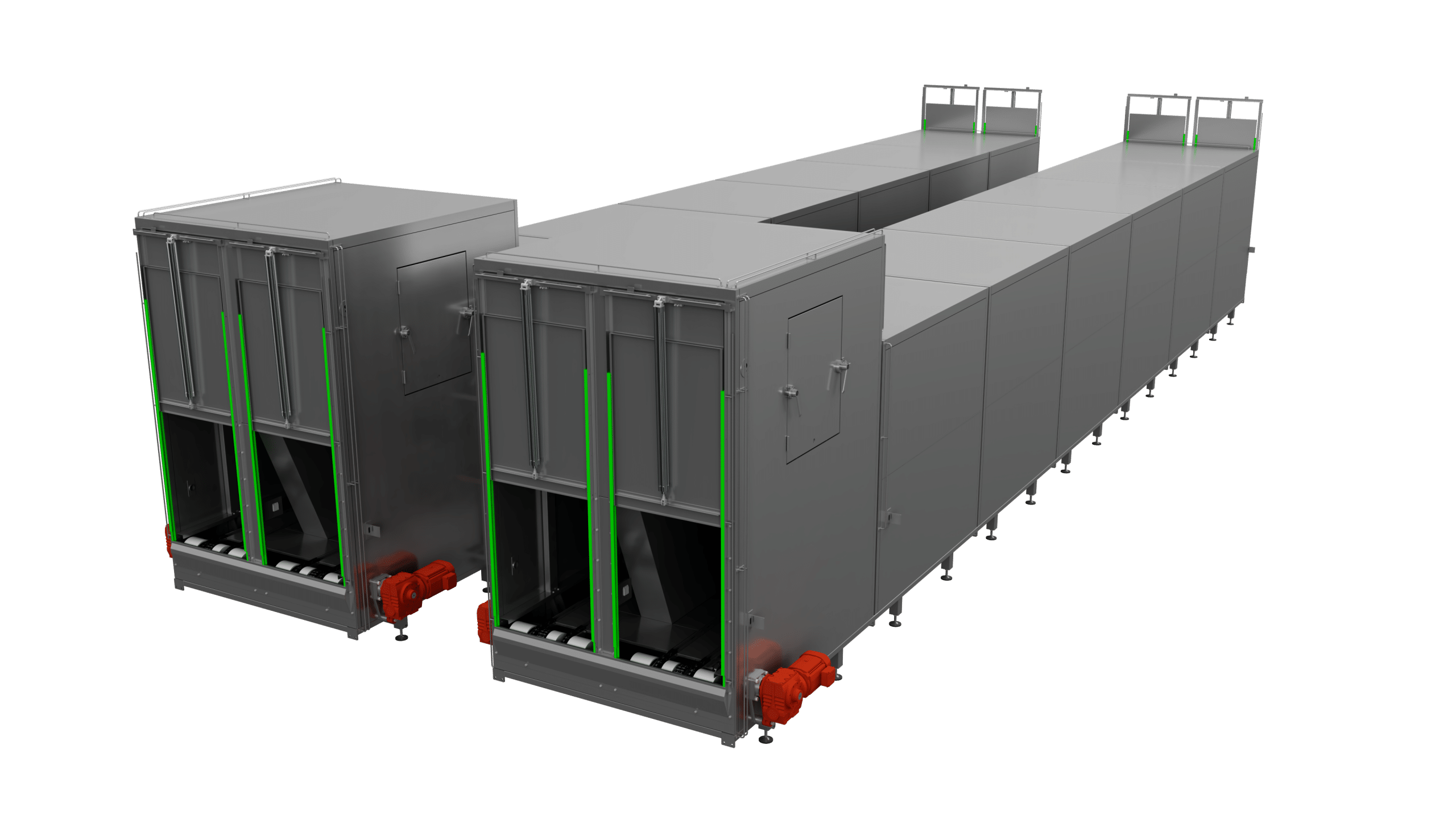

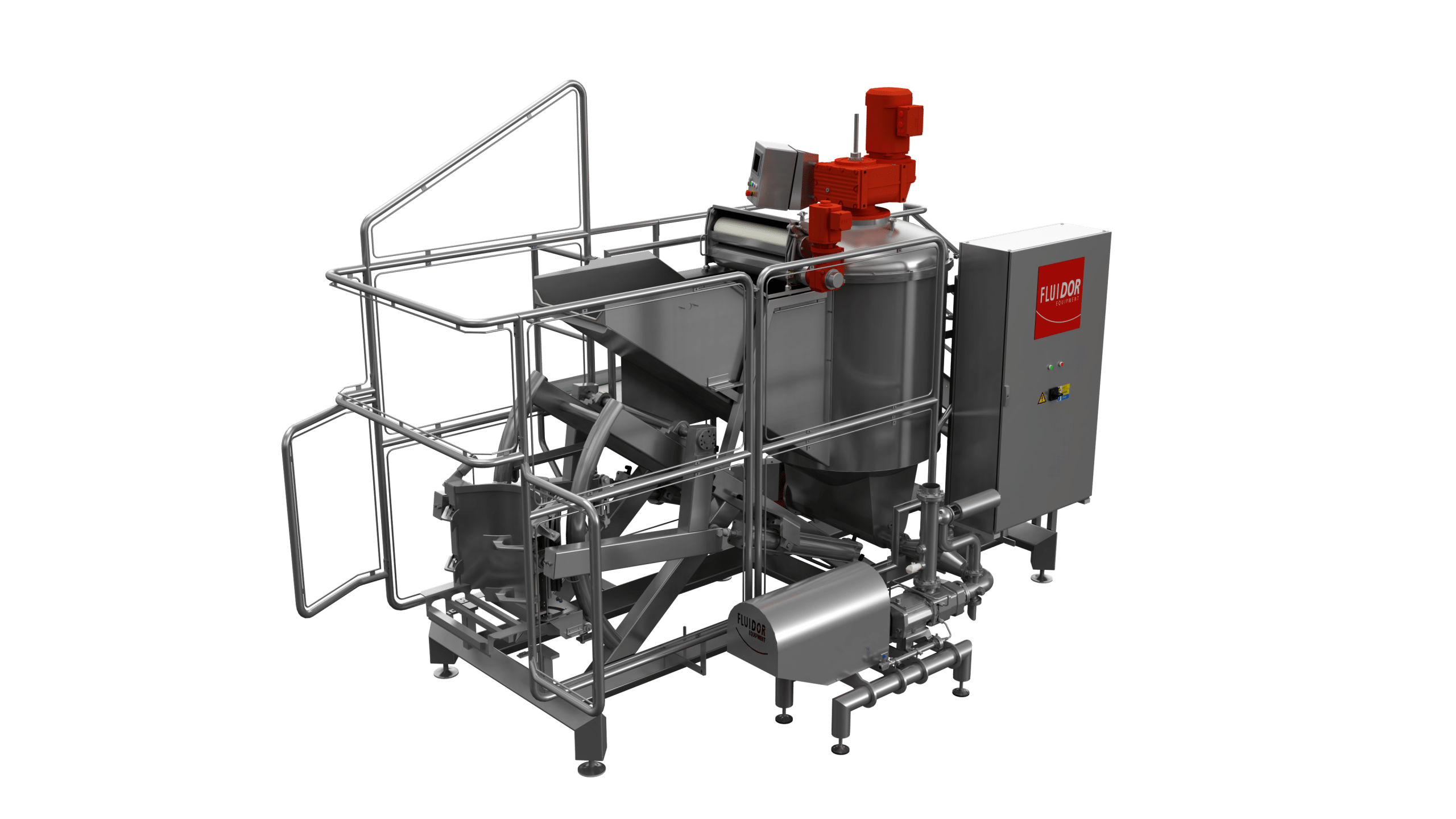

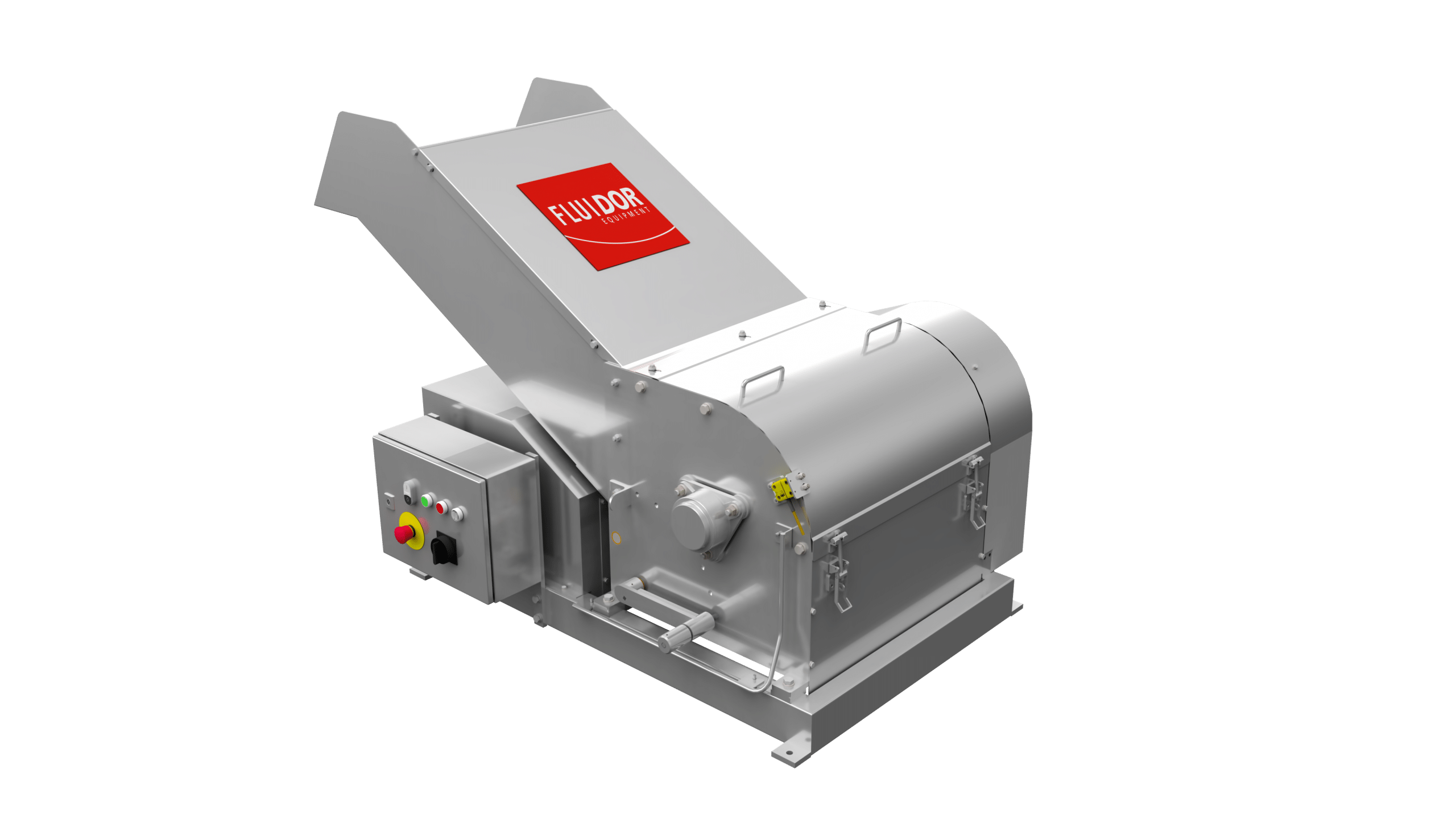

With the Crushed Ice-Melter (CIM), you can automatically melt ice flakes produced by the Drum Dumper Ice Crusher and enhance product flow efficiency.

Melt ice flakes and speed up your process

Does your industry require efficient and controlled melting of ice flakes for subsequent processing steps?

The Crushed Ice-Melter (CIM) from Fluidor Equipment is designed for melting ice flakes produced by the Drum Dumper Ice Crusher with precise temperature control and seamless integration and flexibility.

How the CIM works:

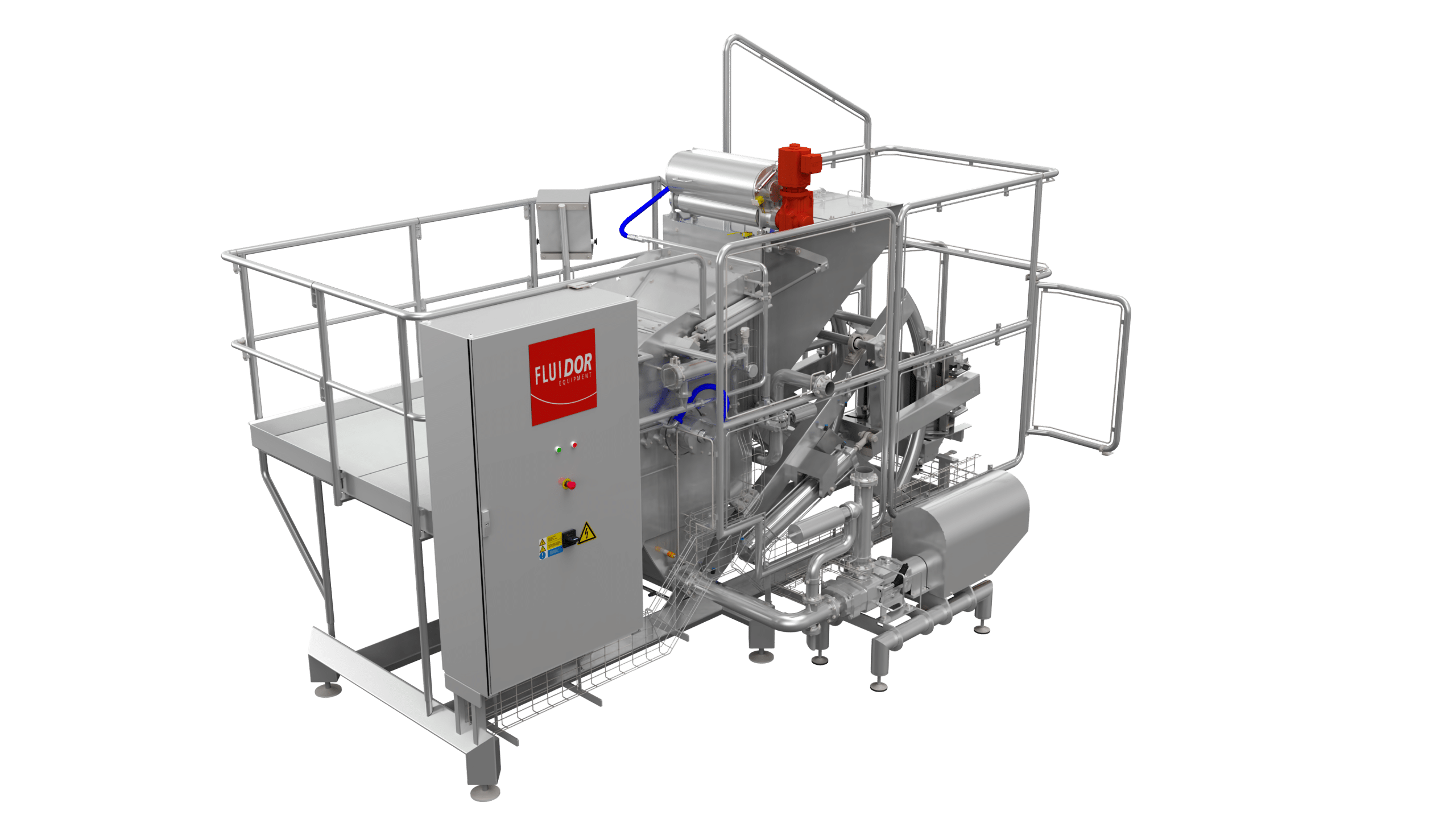

- The hot service water of max. 80°C can be supplied by the operator directly, or created by the steam/hot water heat exchanger that is mounted on the same skid (steam version). This skid can be installed straight next to the Fluidor Drum Dumper Ice Crusher.

- The product is warmed up in double walled piping with proportionally controlled service water to a homogeneous compound of around 0 °C.

- The service water will not exceed 50 °C to avoid over-pasteurization of the product.

- The required energy for the melting process of the product depends on: structure, specific weight, entrance temperature, specific heat, quantity of insoluble solids (dry solids %), quantity of soluble solids (Brix), pump speed.

- The adjustable discharge temperature is normally set just above the melting point of the product with a deviation of approx. 2 °C, depending on the product flow.

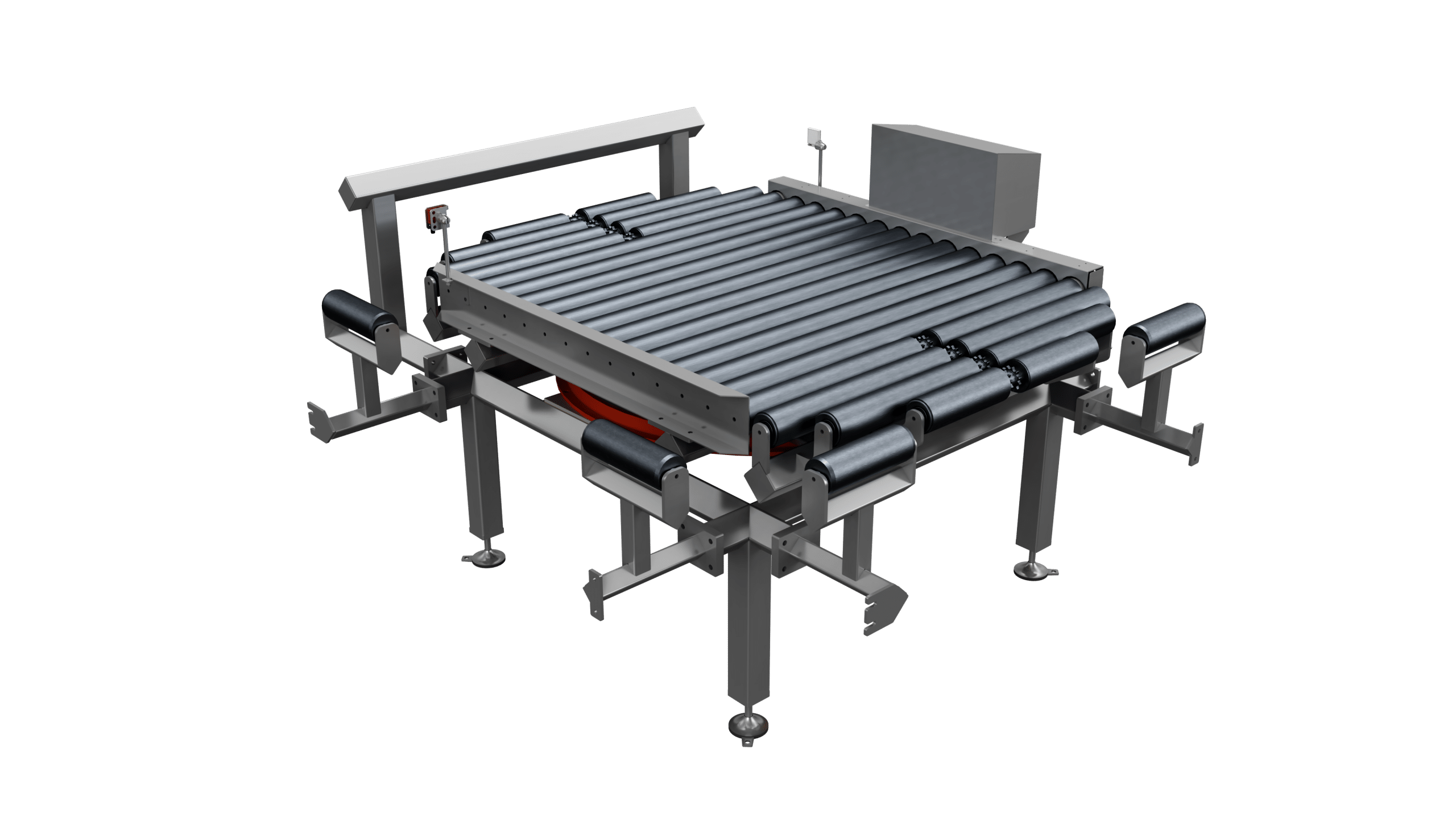

- The product then can easily be pumped to the next process step by the product pump of the Drum Dumper Ice Crusher.

The CIM efficiently melts ice flakes to create a homogeneous mixture, for a smooth product flow to the next processing step.

The CIM maintains the product temperature just above the melting point without exceeding 50 °C, preserving the quality of the product.

The CIM provides flexibility in installation and operation, making it adaptable to various production environments.