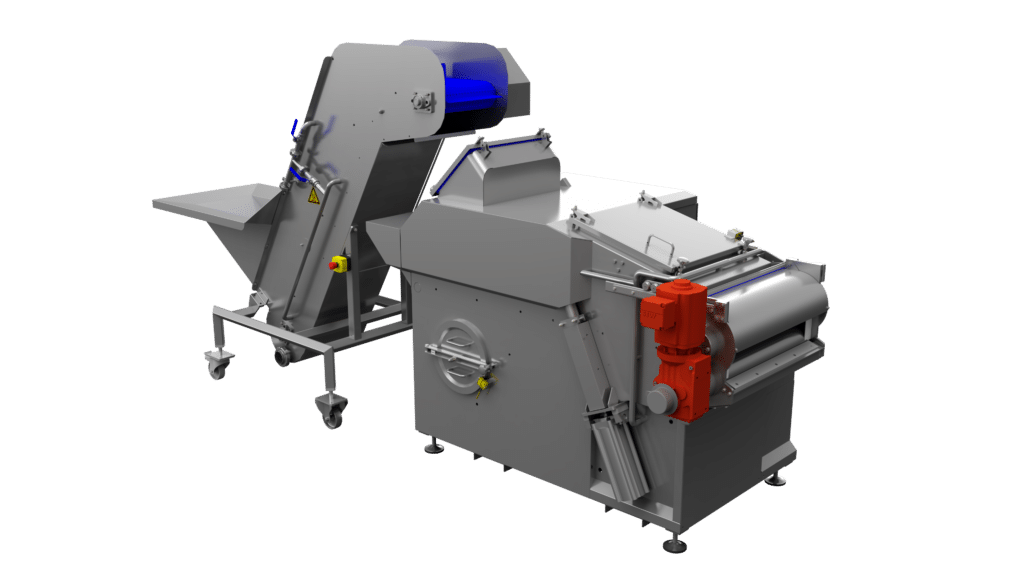

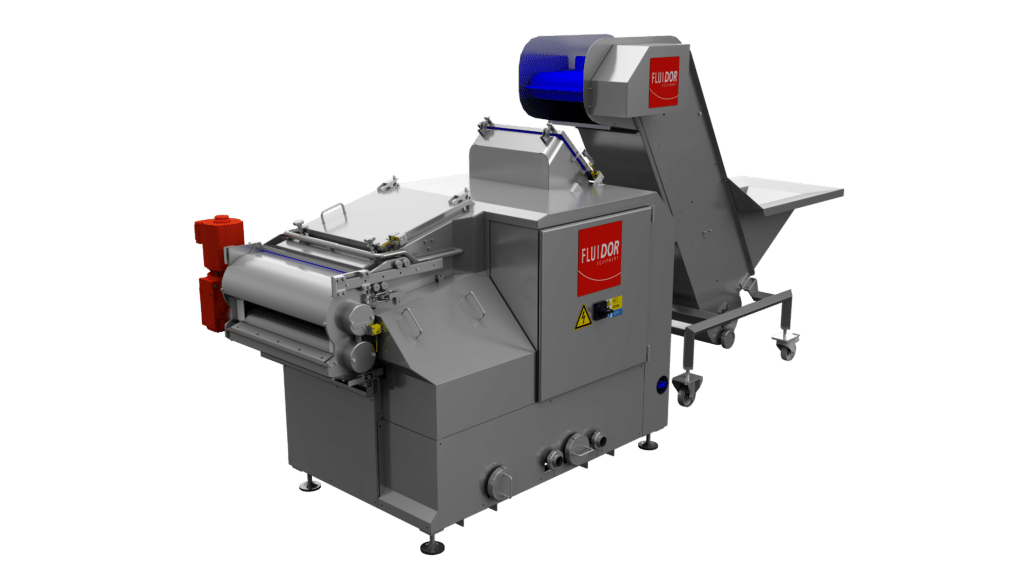

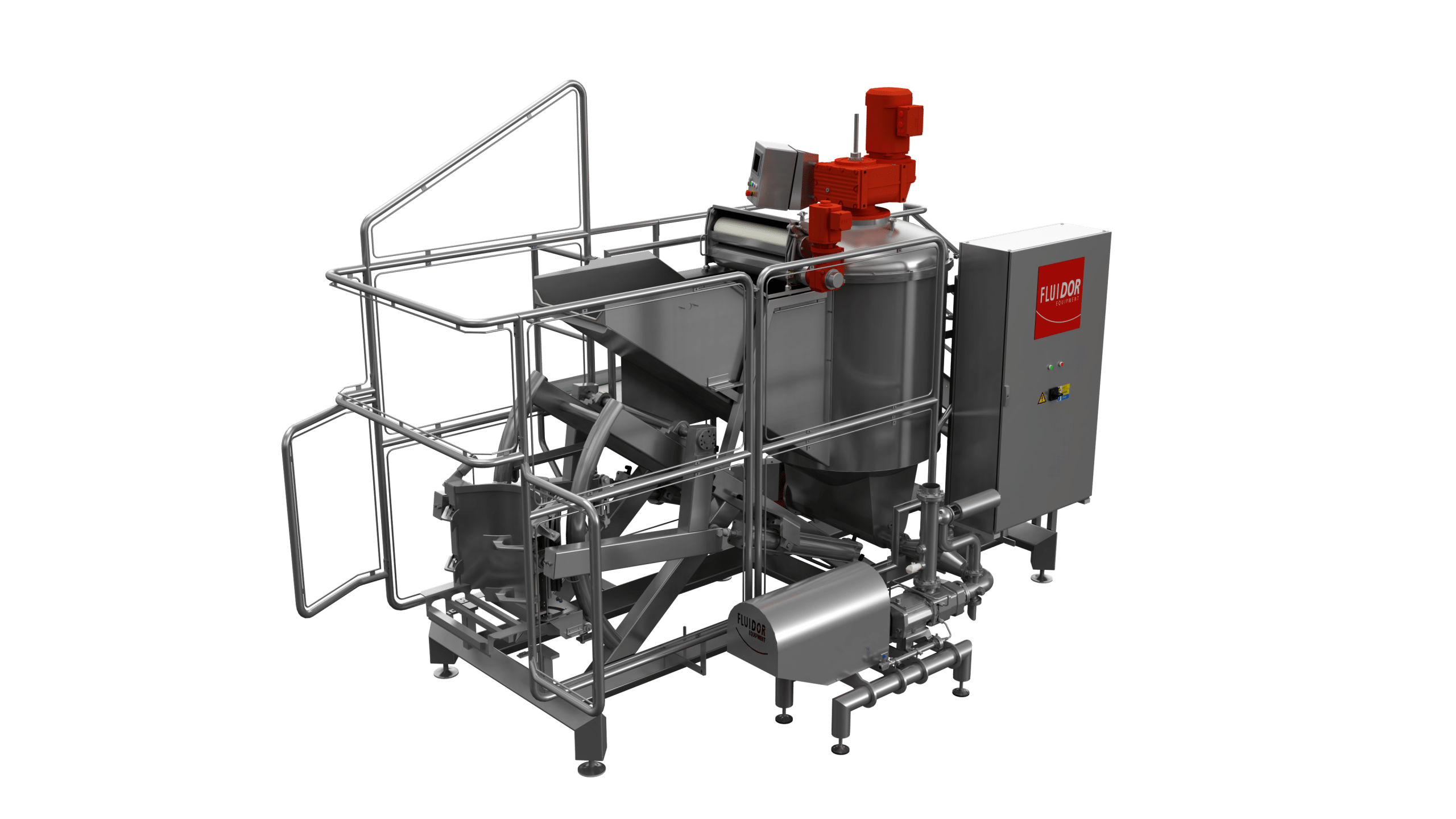

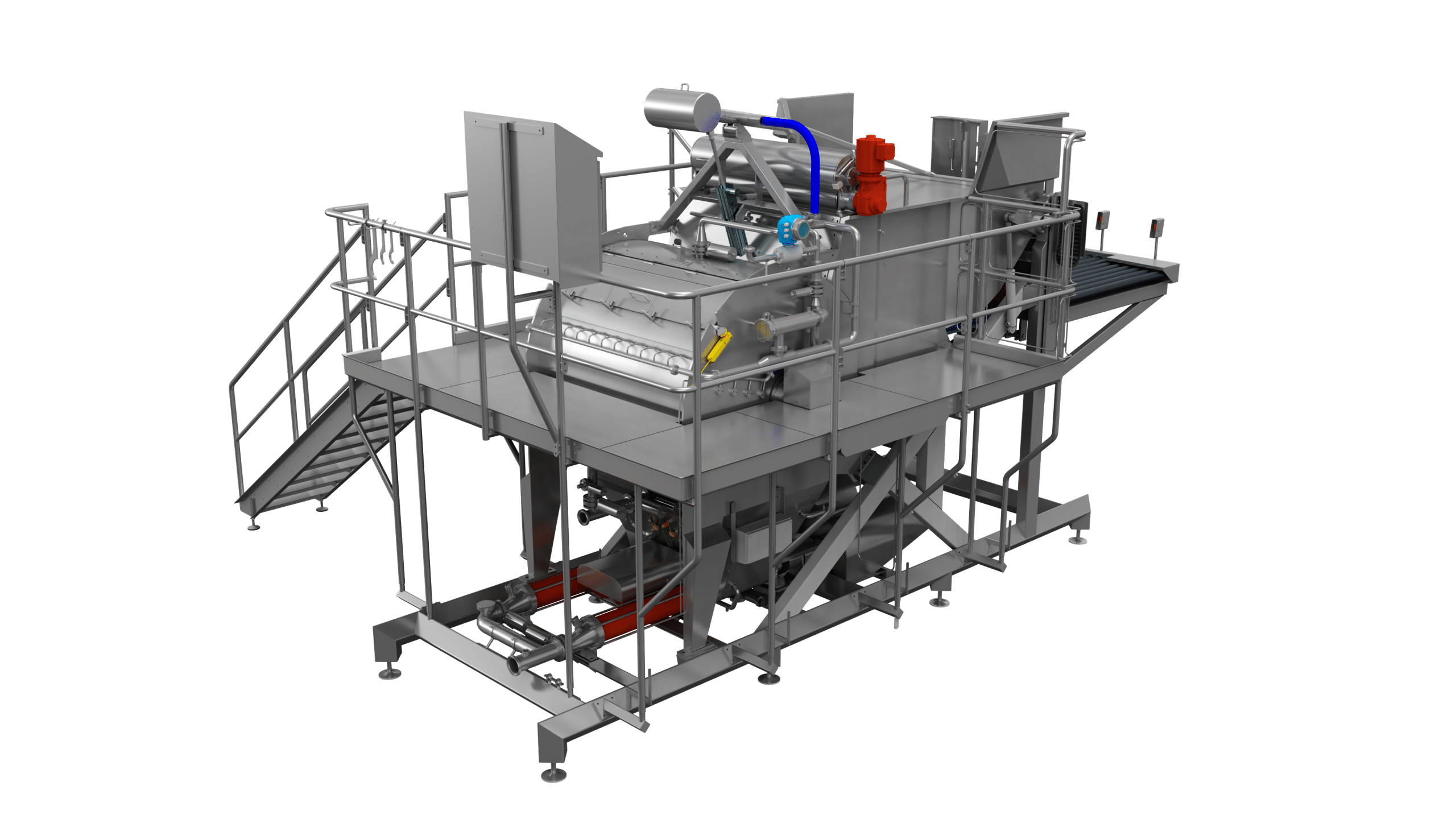

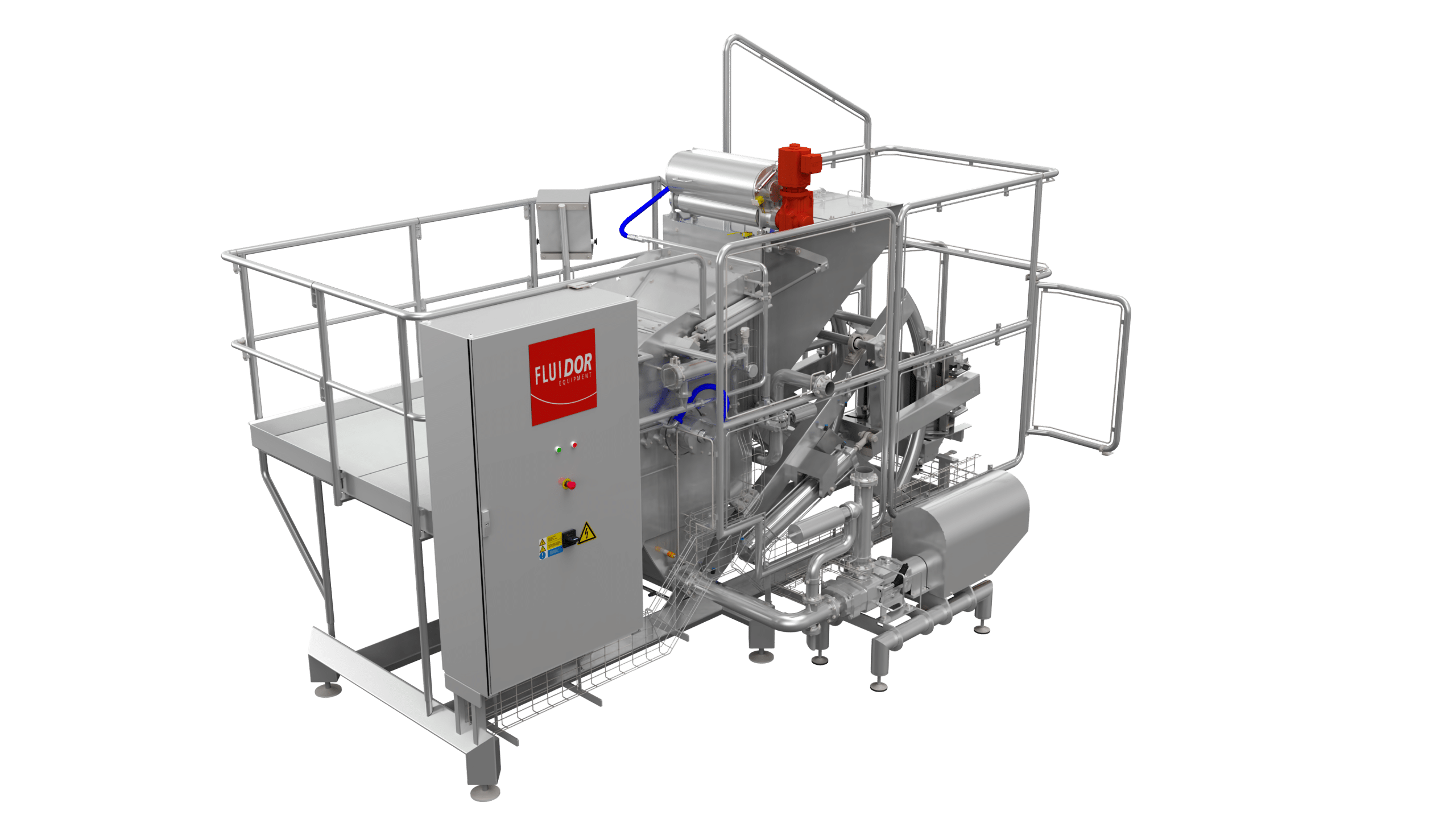

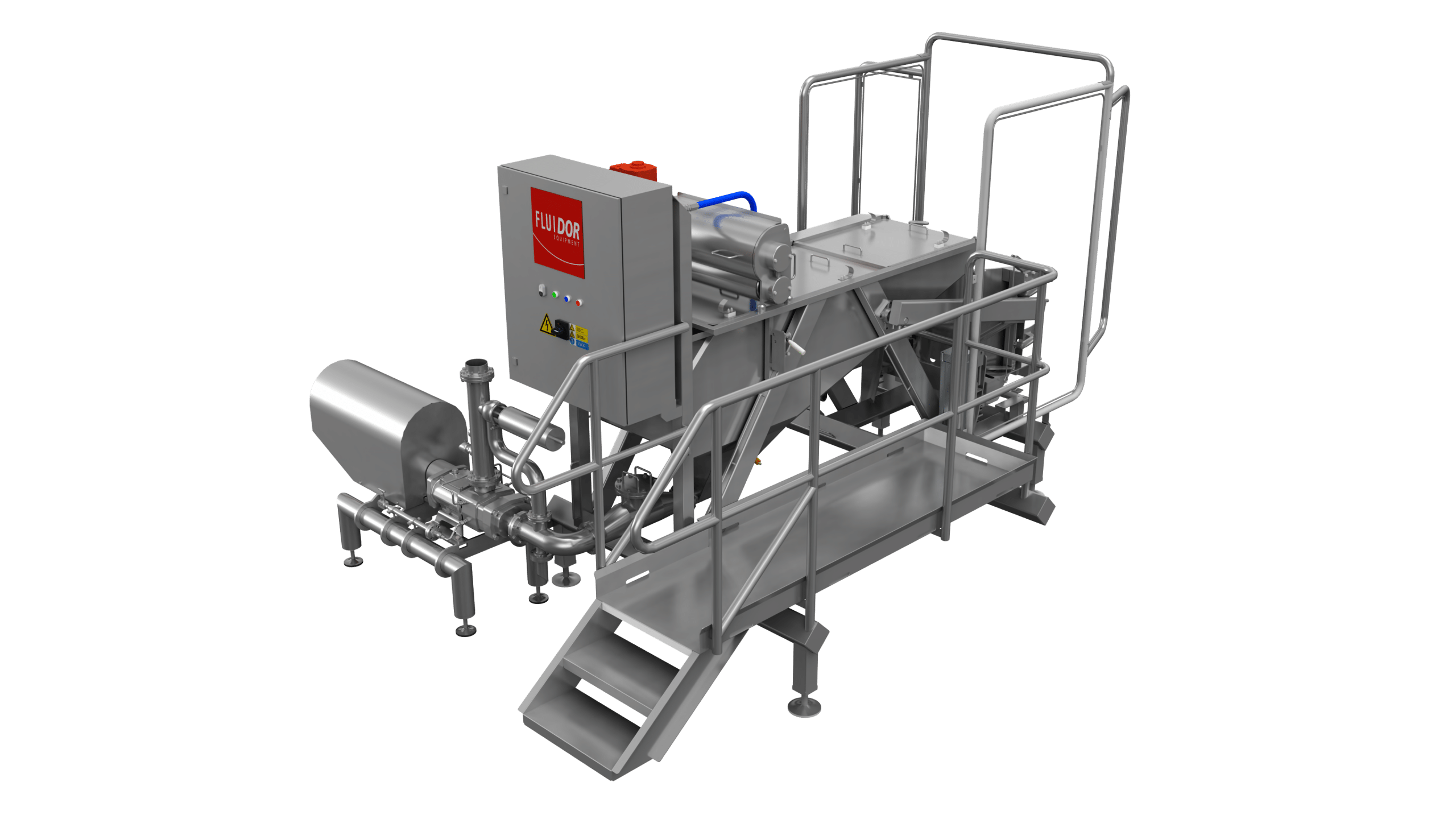

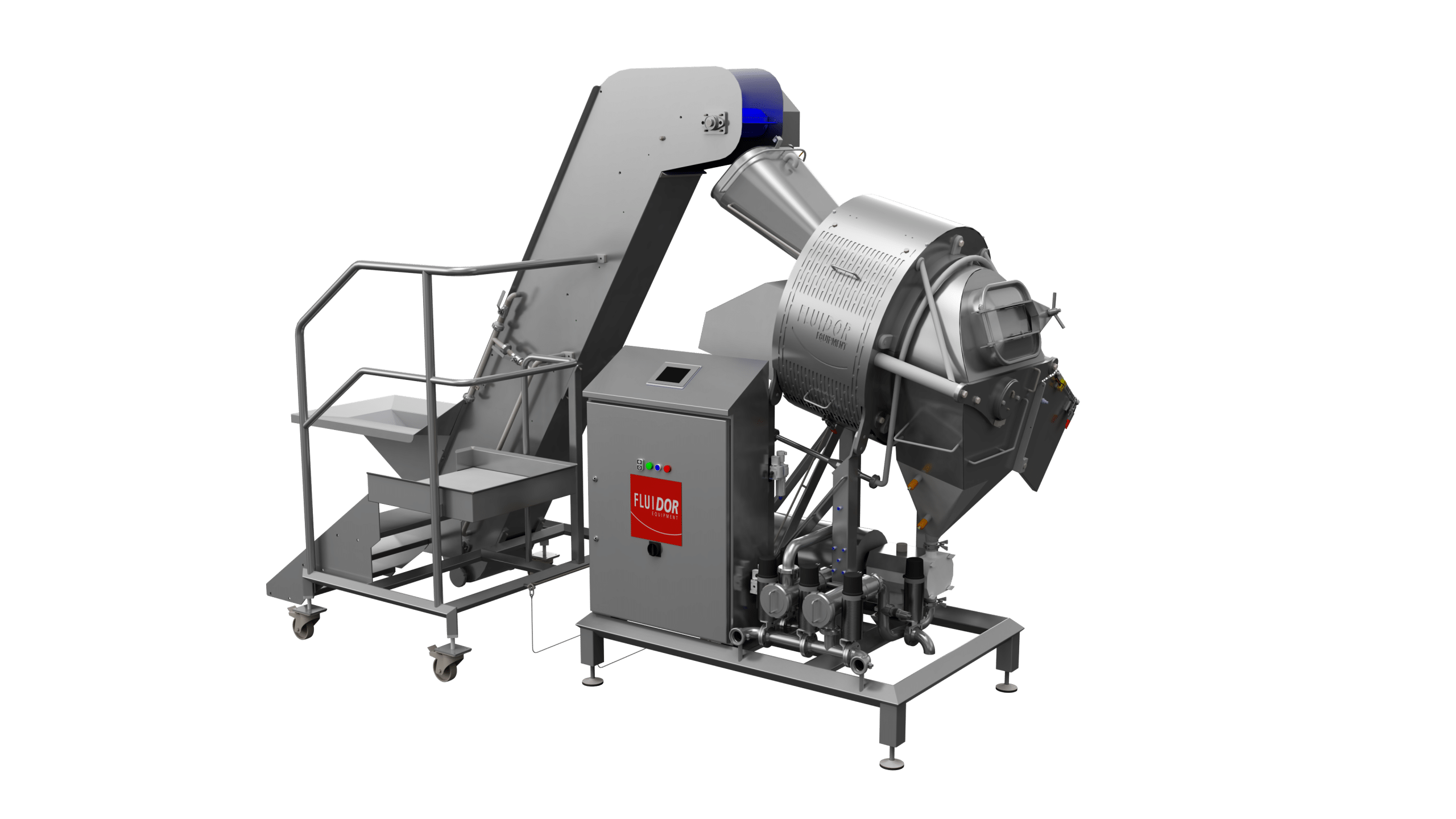

Carton Squeezer BMPS

With the Carton Squeezer BMPS, you can recover product by separating the liquid product from its packing. Maximise product recovery, minimise waste.

Maximise liquid product recovery from packing

Does your industry wish to recover product by separating the liquid product from its packing?

The Fluidor Carton Squeezer, type BMPS, is designed for processing cartons, with or without plastic screw caps. Benefit from maximised product recovery, versatile and automated operation and enhanced hygiene and safety.

Depending on the infeed and your product, it can handle up to 4.000 cartons per hour.

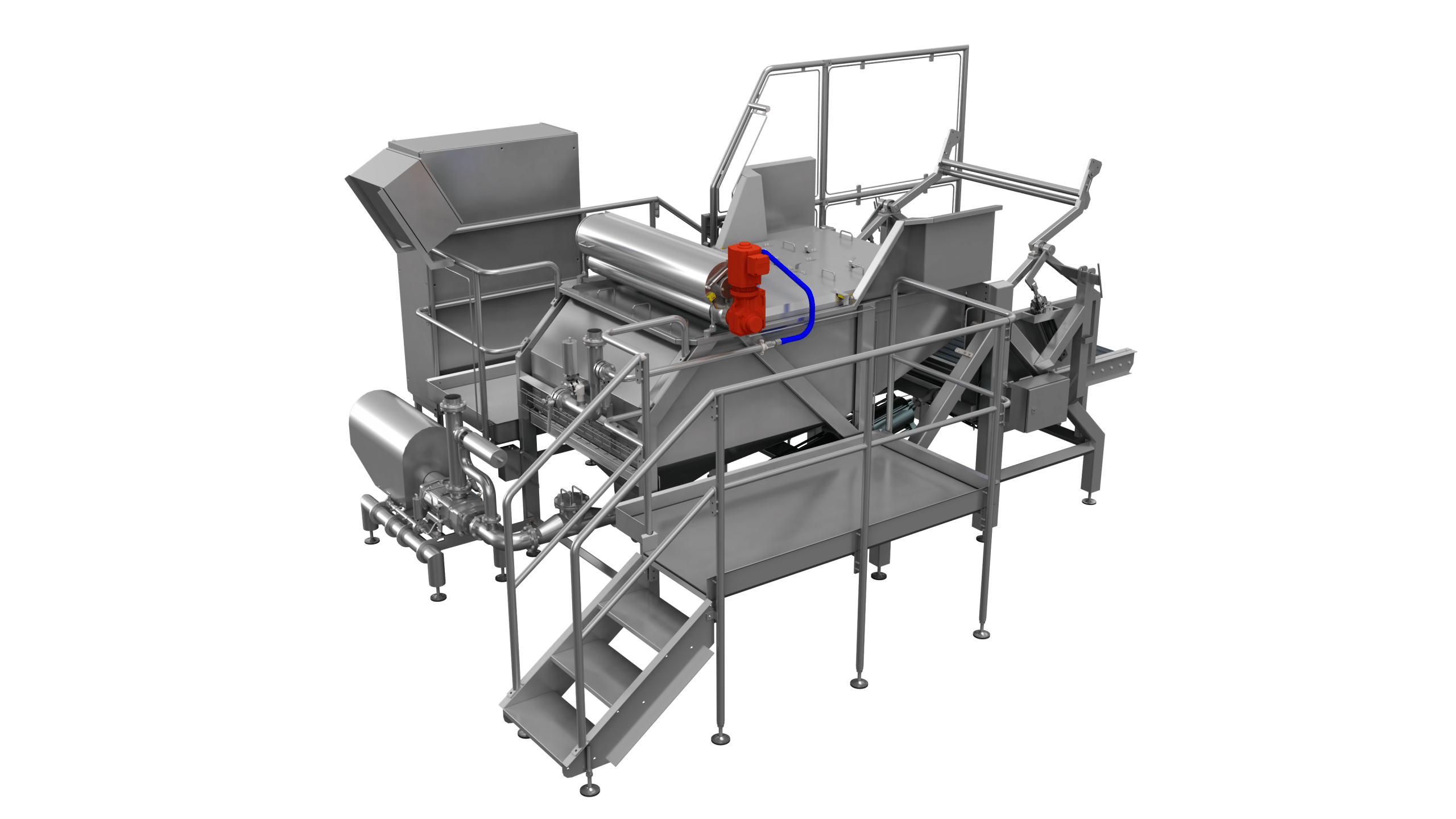

How Carton Squeezer BMPS works:

- The product is collected, filtered and discharged by a centrifugal pump for your next process steps.

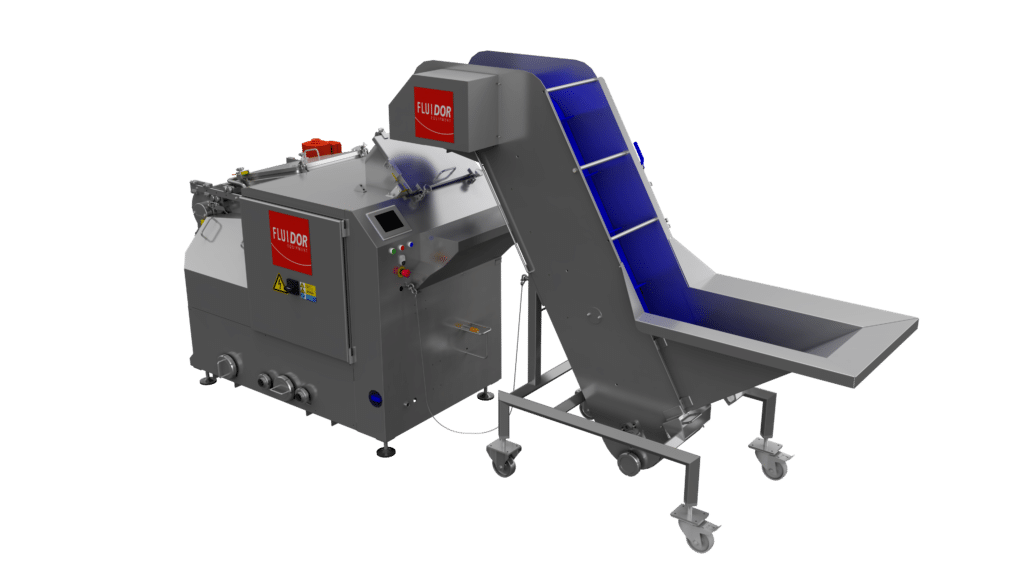

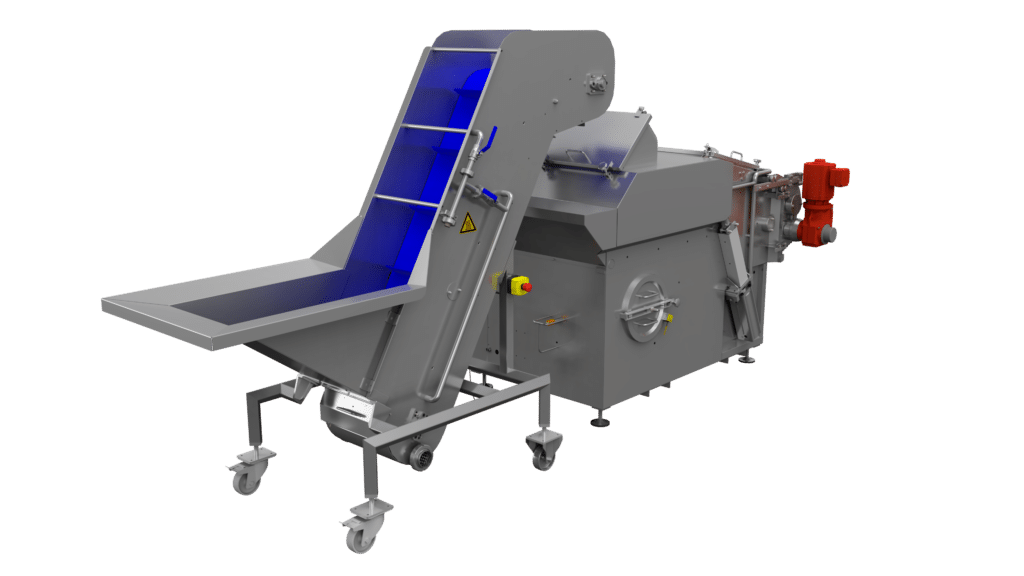

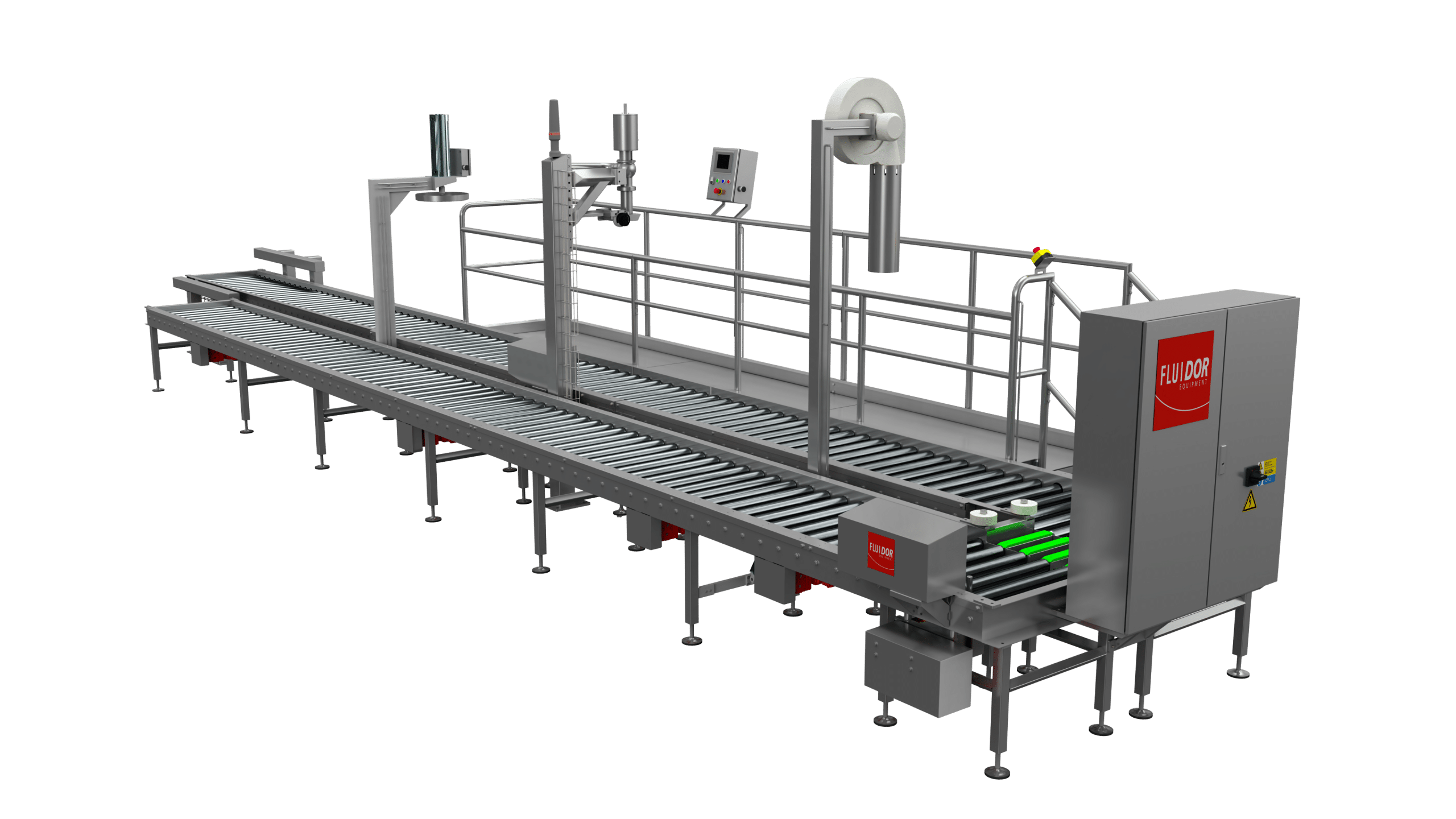

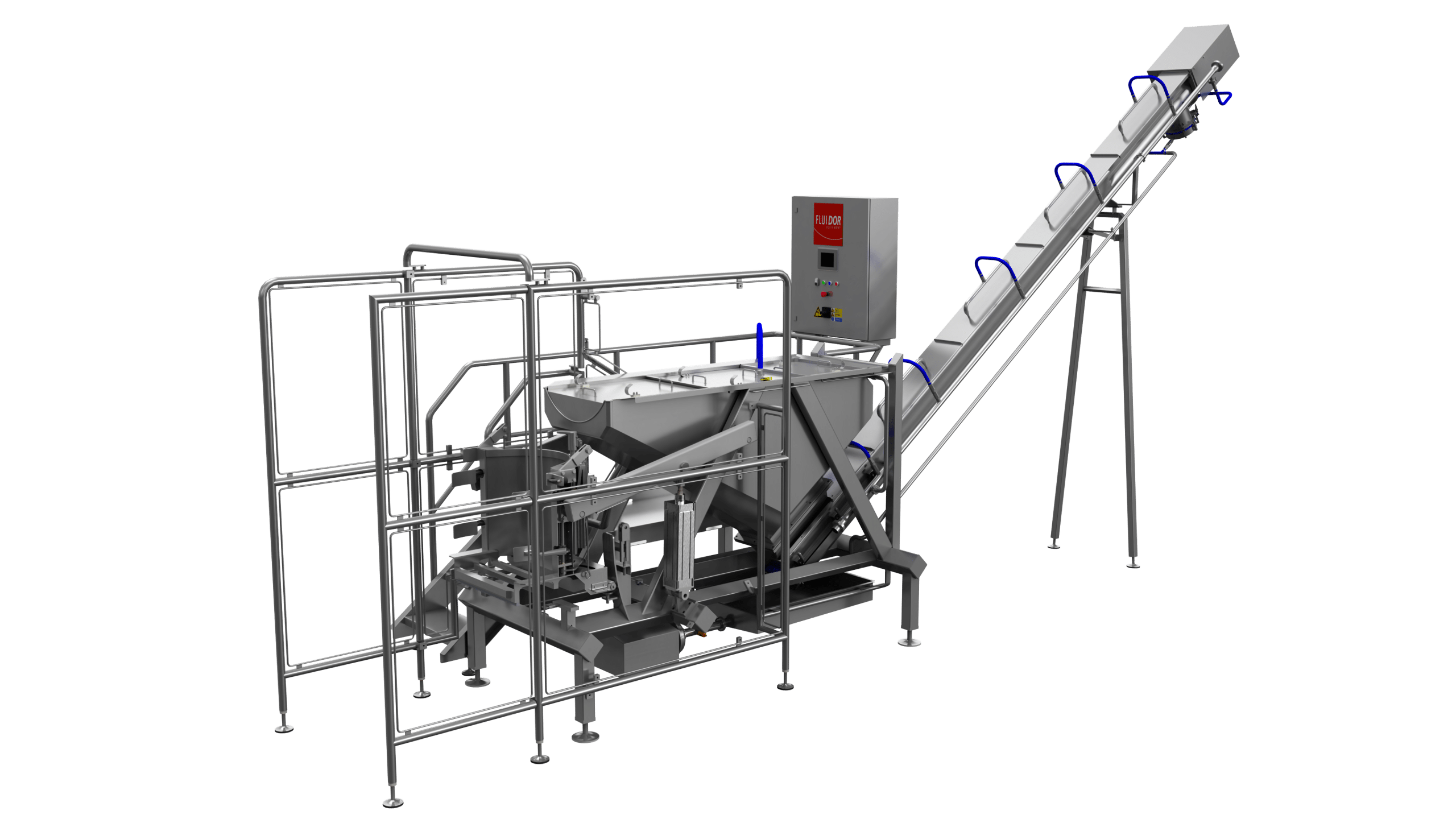

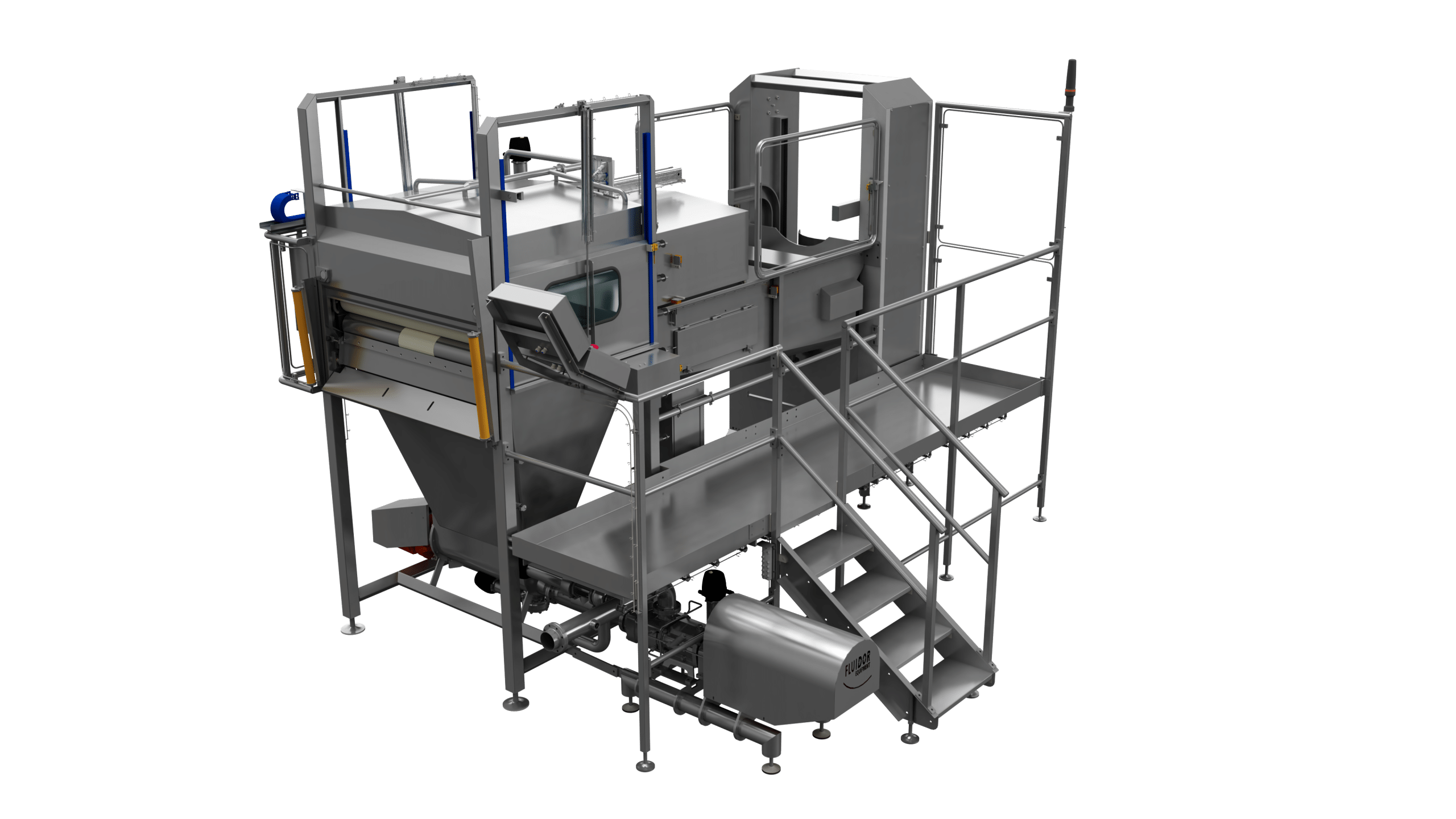

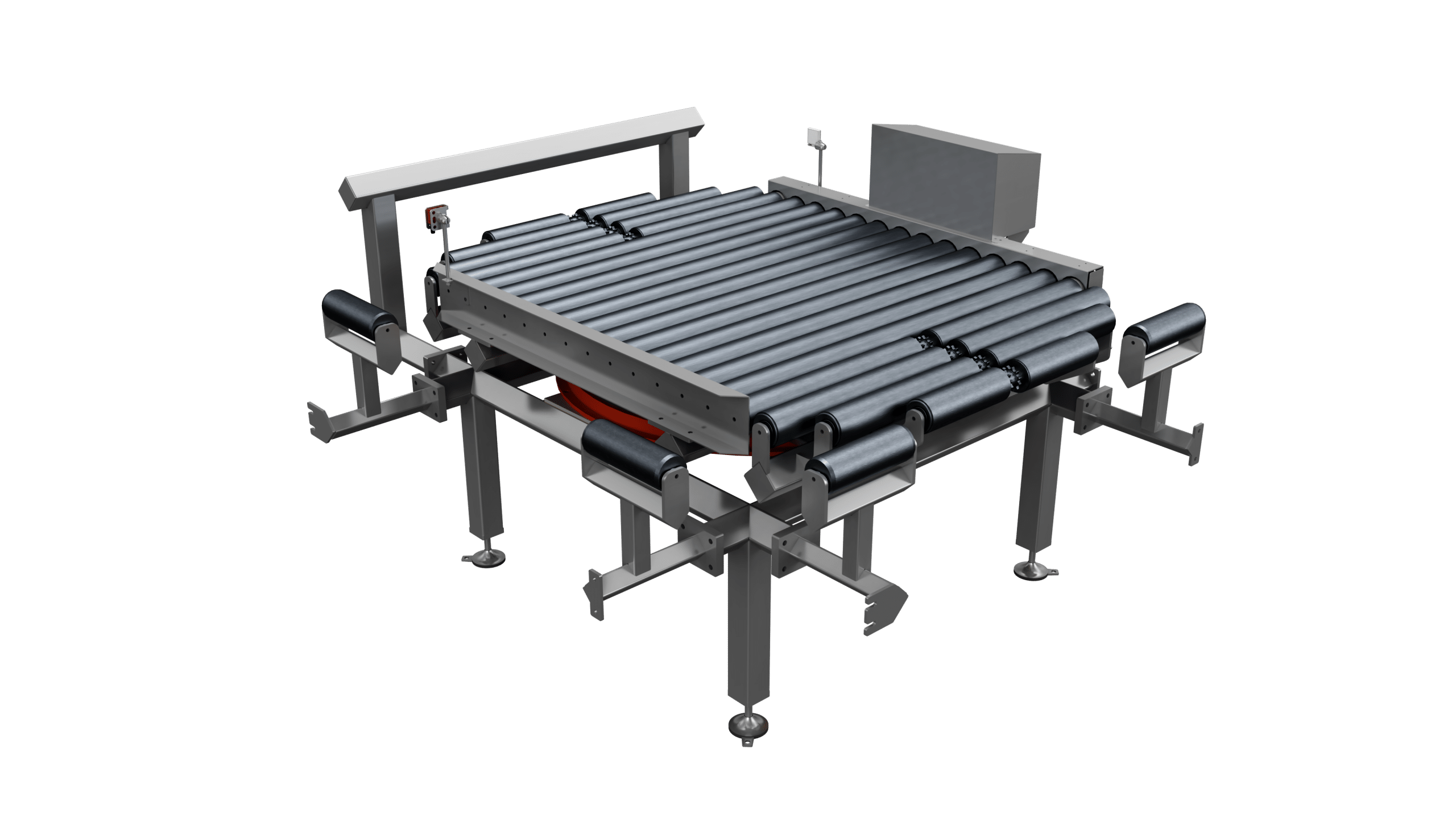

- For controlled loading of cartons, we advise our Loading Conveyor, but loading can also be done manually or by connecting to other automated conveyor systems.

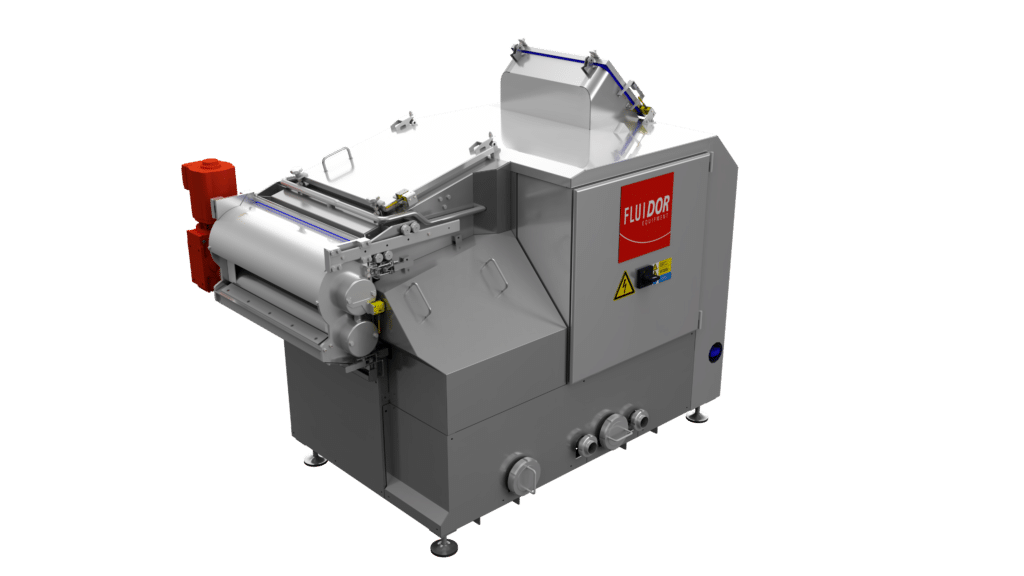

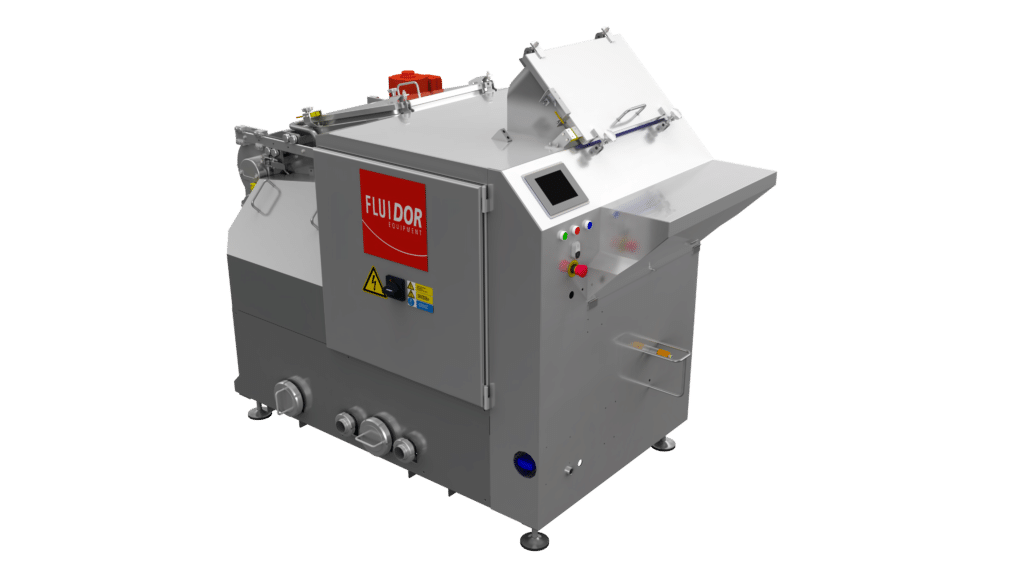

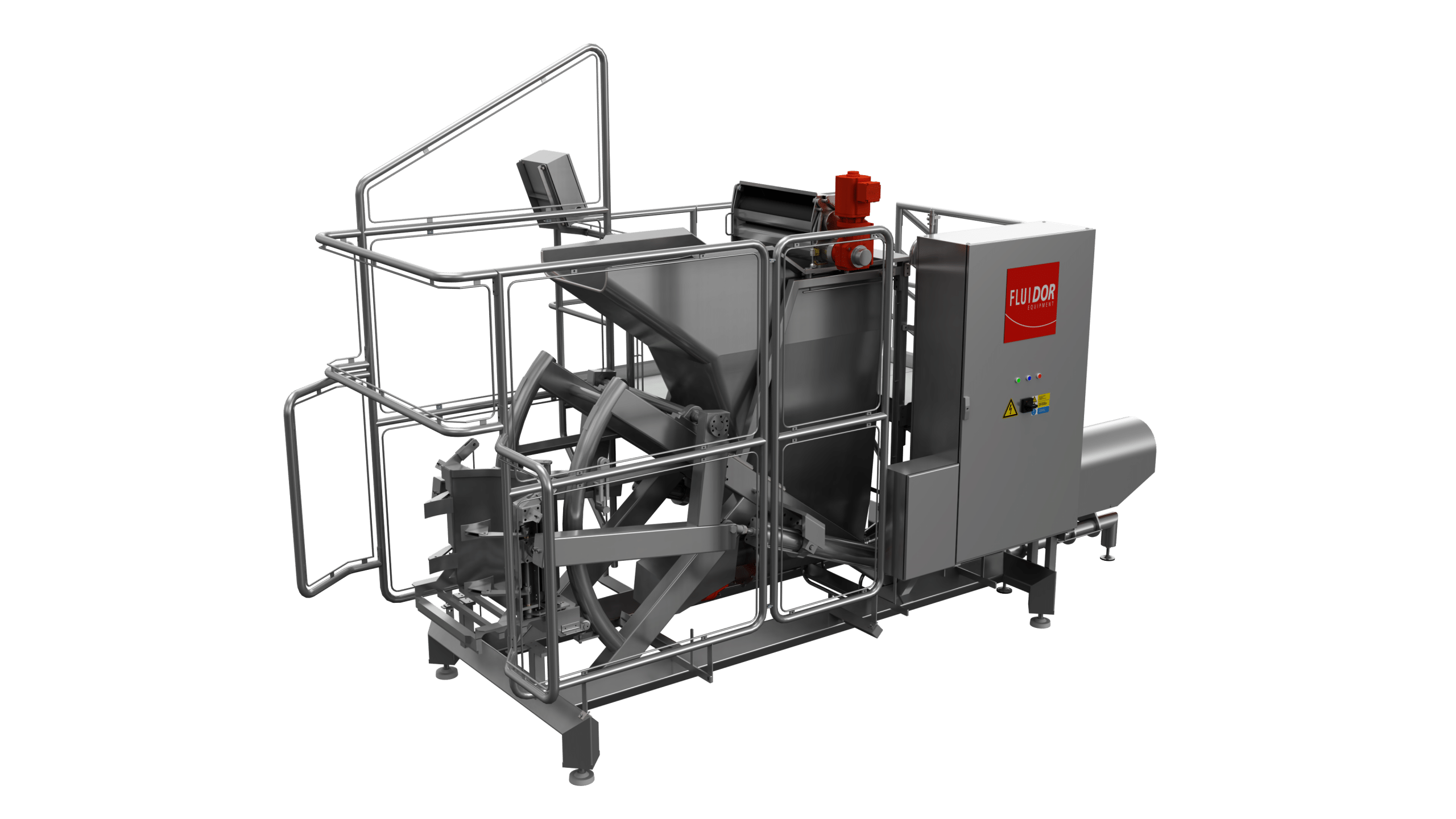

- The cartons drop on a driven belt conveyor and are pressed open by a pneumatic operated press plate.

- After opening, the remaining product in the cartons is squeezed out by an electric driven hygienic squeezer.

- Empty cartons fall into a container or discharge conveyor and are ready for a paper compacting press.

BMPS efficiently squeezes out remaining liquid from cartons and ensures maximum recovery of the product, reducing waste and increasing yield.

BMPS can be integrated with automated conveyor systems or manually loaded. For flexibility in operation and set-ups, improving overall efficiency.

BMPS uses an electrically driven hygienic squeezer and pneumatically operated press plate for high hygiene standards, ensuring the quality of the recovered product.