Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on THAWING TUNNEL

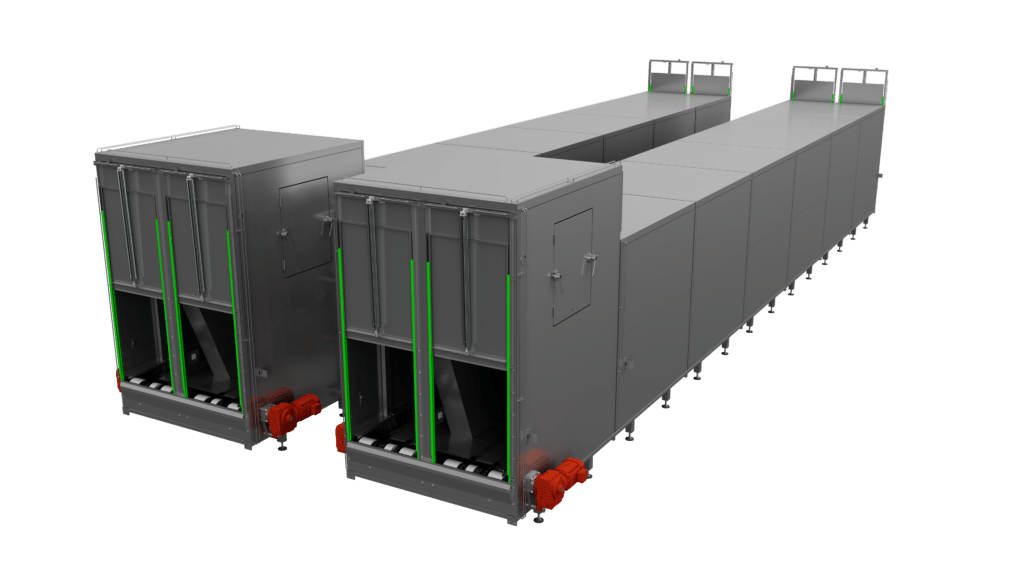

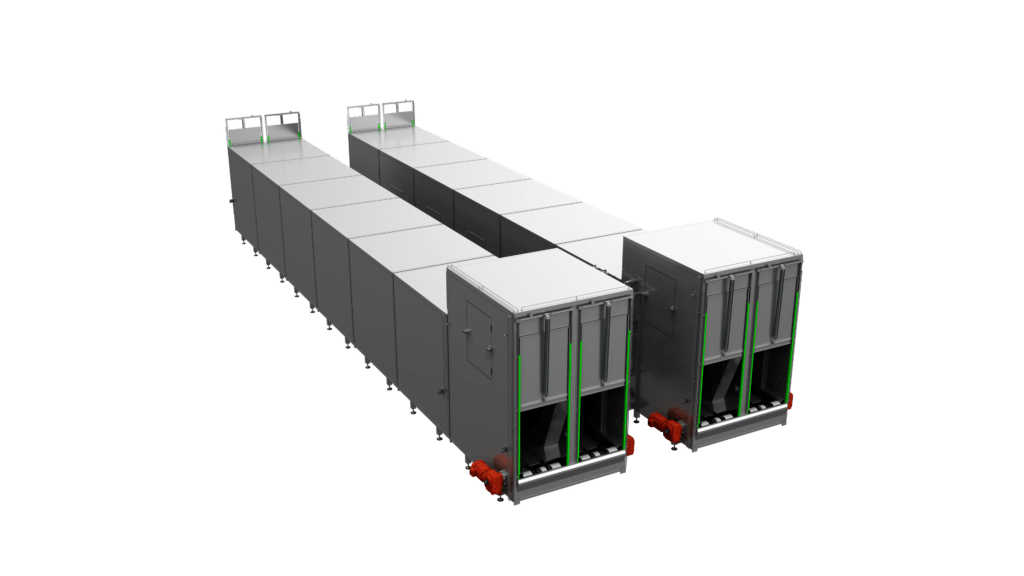

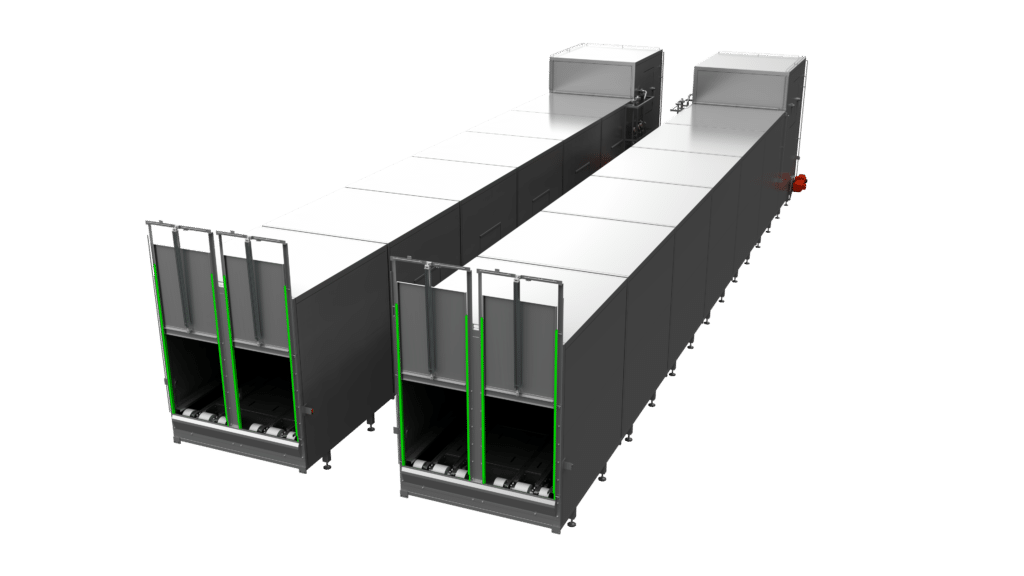

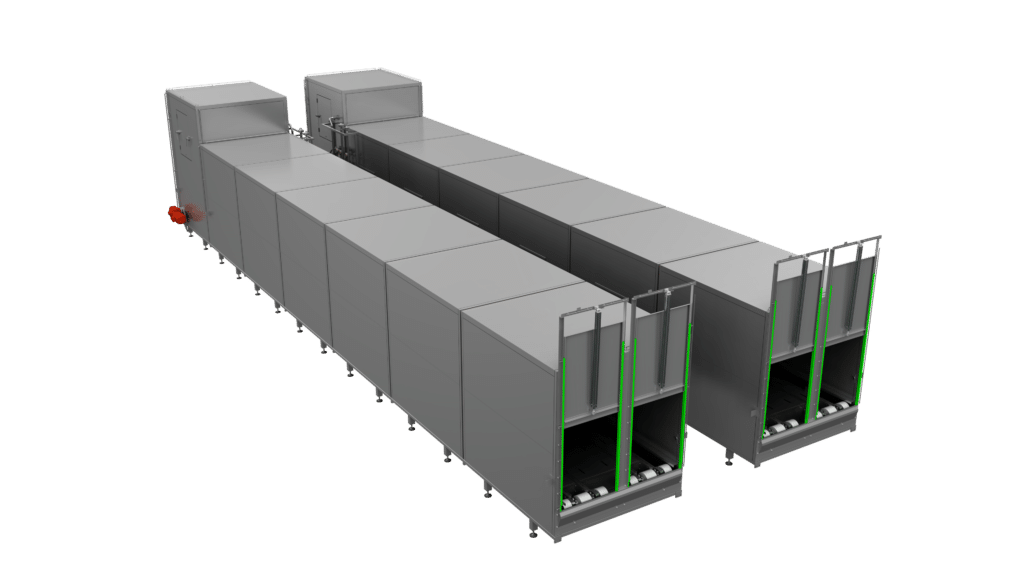

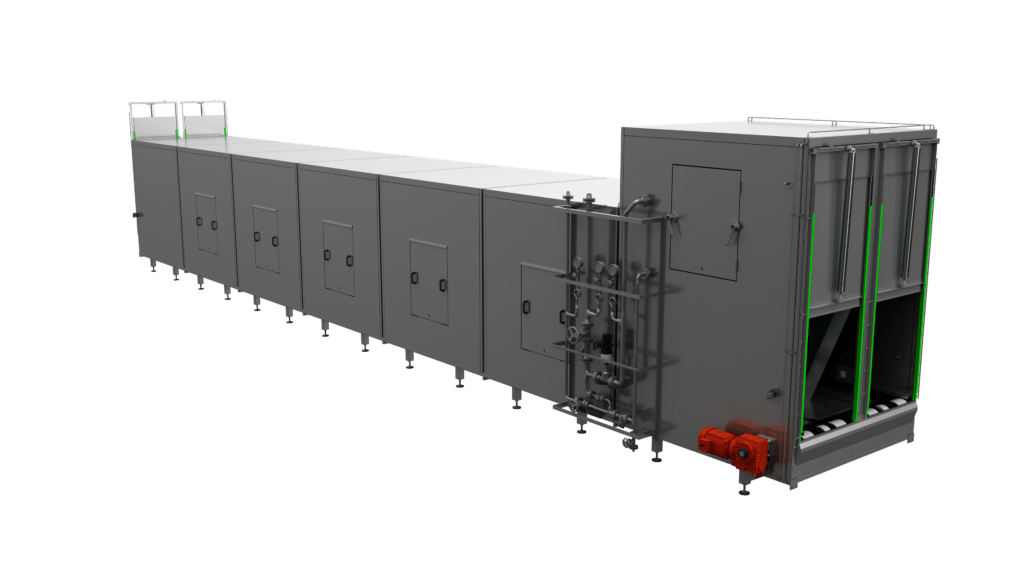

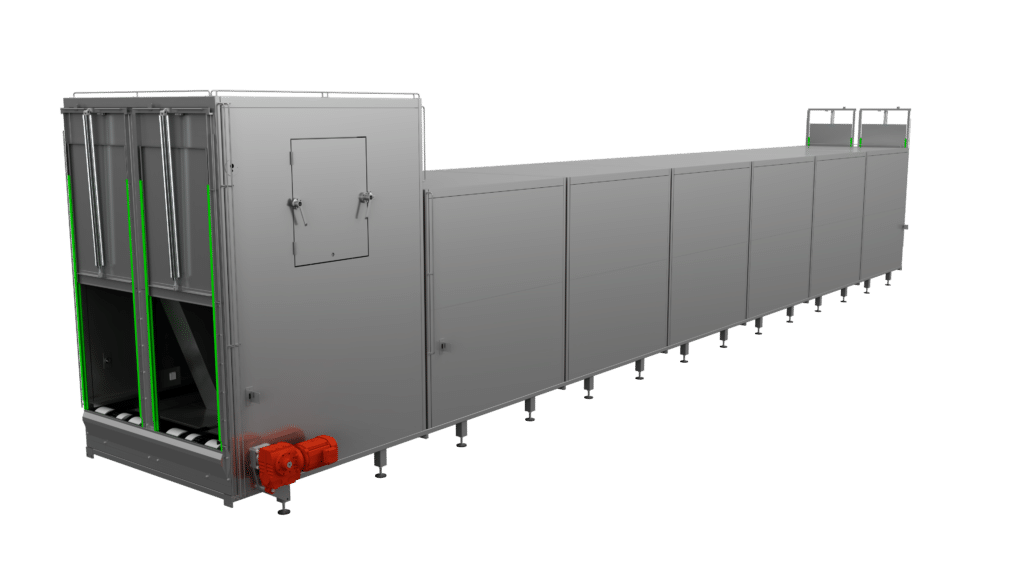

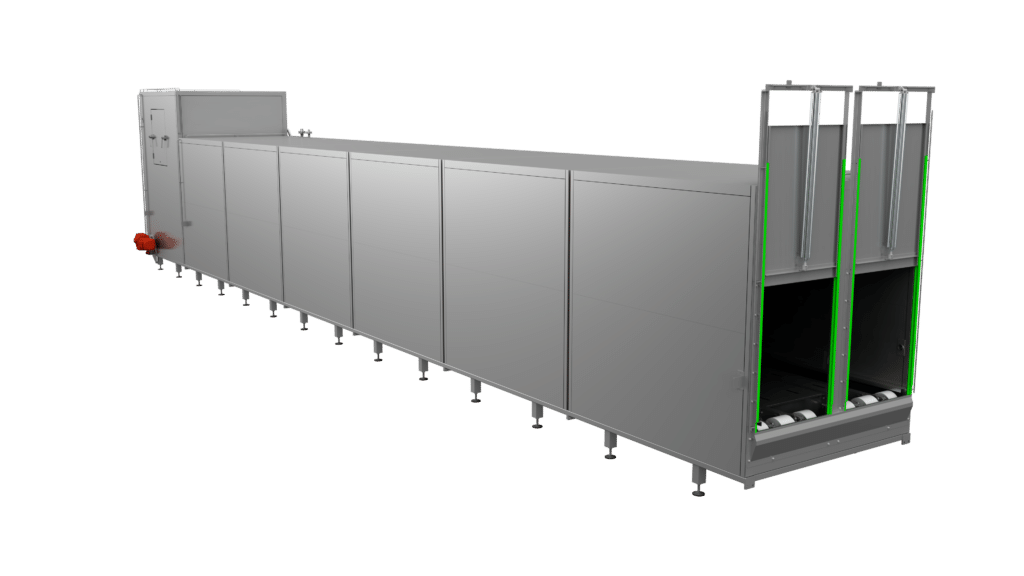

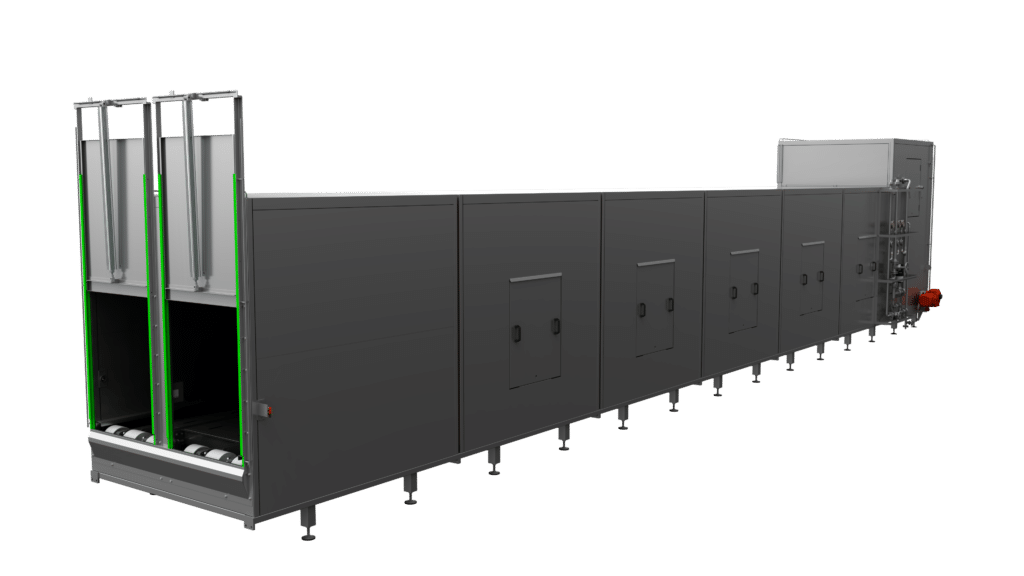

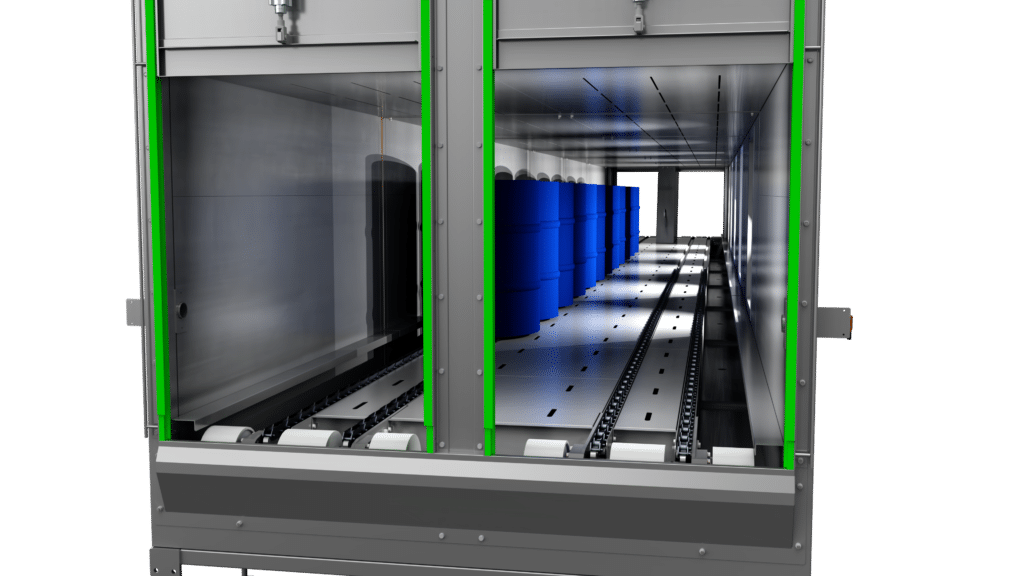

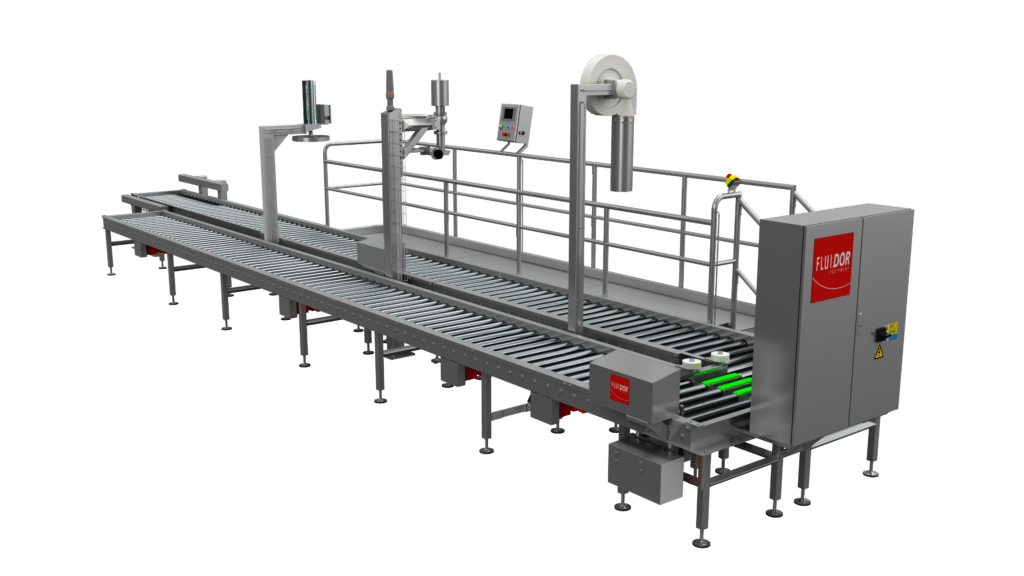

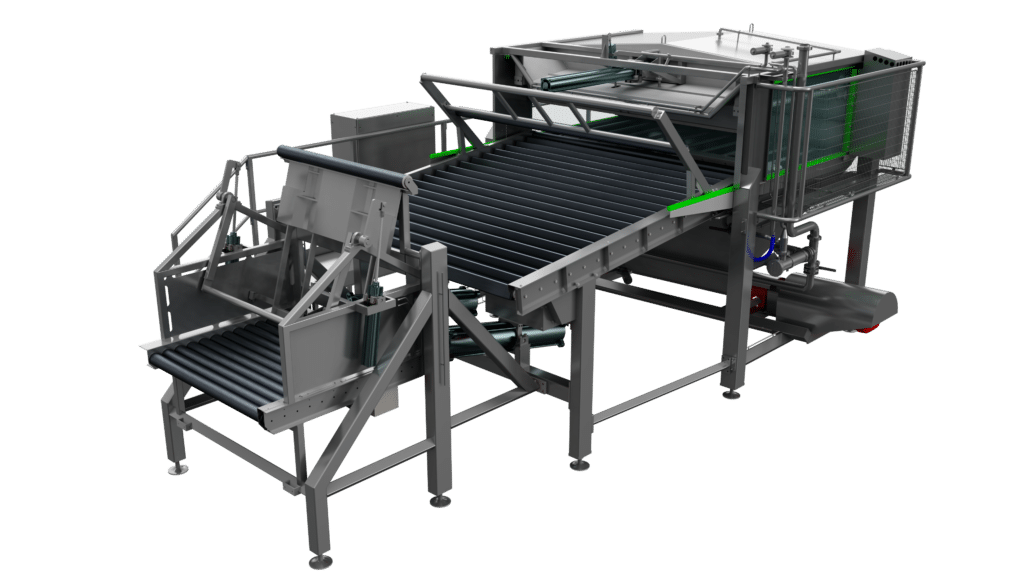

Pre-thaw deep-frozen products for easy tipping of drums

Does your industry require efficient and controlled pre-thawing of deep-frozen products in order to enhance processing efficiency?

The Fluidor Thawing Tunnel is designed to pre-thaw the outer shell of ice blocks, allowing for easy tipping of 200 litre drums containing deep-frozen fruit juices, fruit pulps and fruit purees.

This thawing process facilitates the release of products from the drum during dumping into the Drum Dumper Ice Crusher (DPRICS). The tunnel improves efficiency and operational flexibility, while preserving your product quality.

Depending on drum infeed & product, the maximum capacity based on batches is 20 drums per hour. For a corresponding maximum capacity to the DPRICS and CIM, two Thawing Tunnels of 32 drums each are advised.

How the Thawing tunnel works:

- Frequency driven shuttles transport the drums in pairs in and out of the Thawing Tunnel.

- Two driven chain tracks take care of the transport inside the Tunnel.

- On top of the Tunnel, hot air is created by circulating air through a steam / air heat exchanger.

- A frequency driven fan circulates the hot air through an air duct from which the air is precisely guided along the drums.

- Only the outer shell and top surface of around 2-3 cm is thawed, the rest of the product remains deep frozen to maintain product quality.

The capacity of the Thawing Tunnel is adjustable by duration time per track or drum and temperature (per tunnel). These parameters make it possible to pre-thaw smaller batches of different products with different pre-thawing times. The modular built configuration offers a flexible pre-thawing process.

Efficient

The Thawing tunnel efficiently pre-thaws only the outer shell of the ice block, facilitates easy tipping and processing of deep-frozen products and speeds up production.

Careful

The Thawing tunnel maintains the core of the product deep-frozen, to ensure the quality of the product is preserved.

Flexible

The Thawing tunnel offers adjustable parameters for different pre-thawing times and modular configuration, which makes it suitable for various product types and batch sizes.

Wednesday, July 17th, 2024 | Geplaatst in: |

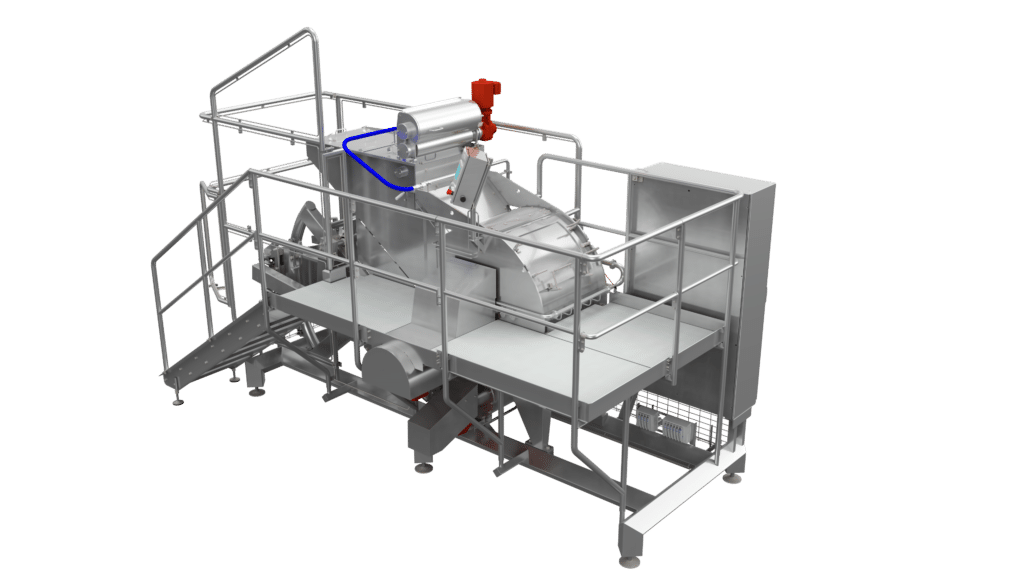

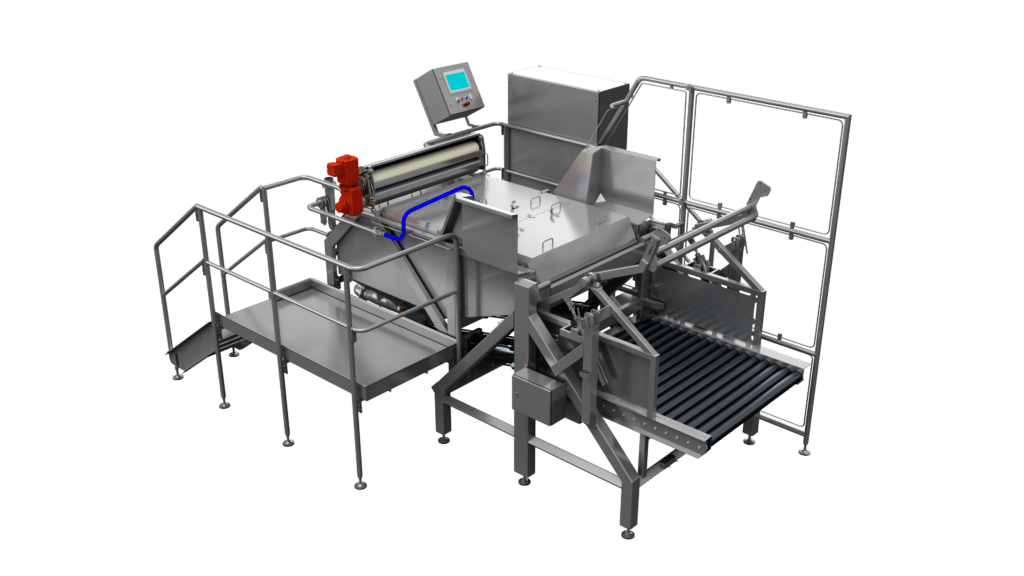

Comments Off on DPRCS

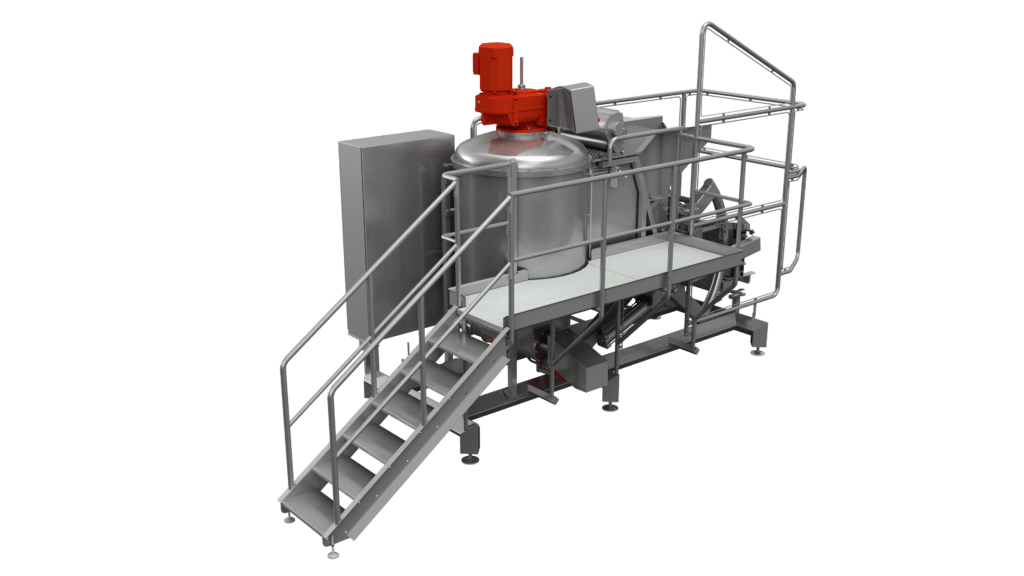

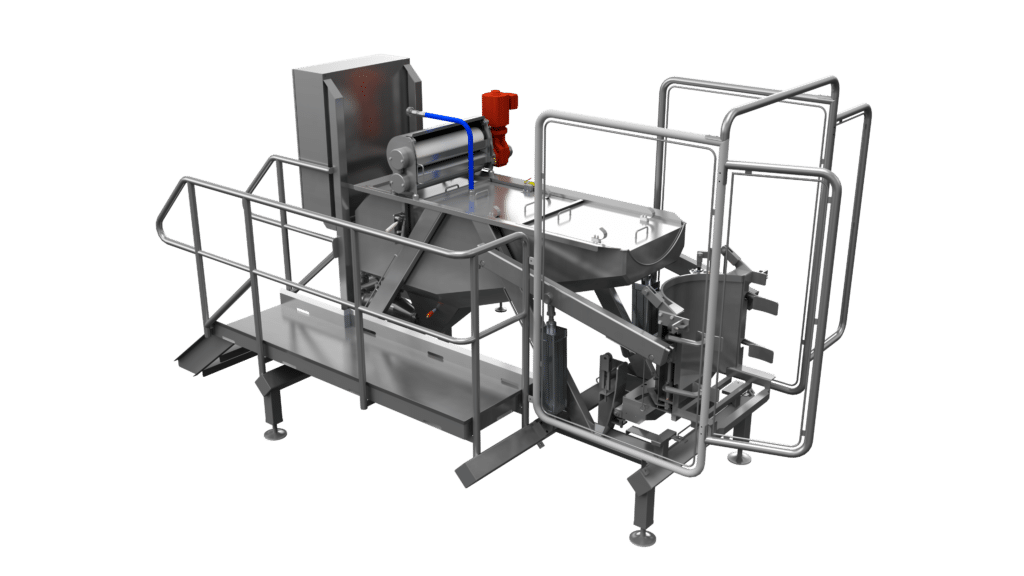

Empty drums with soft frozen liquid products

Does your industry benefit from emptying drums with soft frozen product and chopping it into smaller pieces?

The Drum Dumper Crusher (DPRCS) is designed for an efficient emptying of 200 litre open top drums containing liquid products like soft frozen fruit juices, fruit juice concentrates (up to 70˚ brix) and honey with a maximum viscosity of 20.000 cP.

Depending on the infeed and your product, it can handle up to 60 drums per hour.

How the DPRCS works:

- After production, the CIP covers can be placed and the DPRCS can be integrated into your CIP process. A complete set of nozzles cleans the inside of the hopper section, according to the set cleaning program.

- The drums are placed on the roller conveyor section, where the lid will be removed and liner(s) will be opened.

- The drum is lifted and tipped pneumatically, the product falls into the collecting hopper and is stopped by a grid.

- The bag will empty itself partly. The operator brings the bottom part of the bag into the squeezer and the remaining product is pressed out.

- The product flows into the hopper, where the vertical chopper takes care of an efficient chopping of soft frozen product.

- Finally, the product is discharged by a screw conveyor and twin screw pump.

Efficient

The DPRCS empties and processes drums efficiently and helps increase production speed and product recovery.

Safe & easy

The DPRCS automates pneumatic lifting and tipping to reduce manual handling. It is food and operator safe and integrates with CIP processes.

Versatile

The DPRCS is suitable for various liquid products and integrates with CIP systems, enhancing operational efficiency and product quality.

Wednesday, July 17th, 2024 | Geplaatst in: |

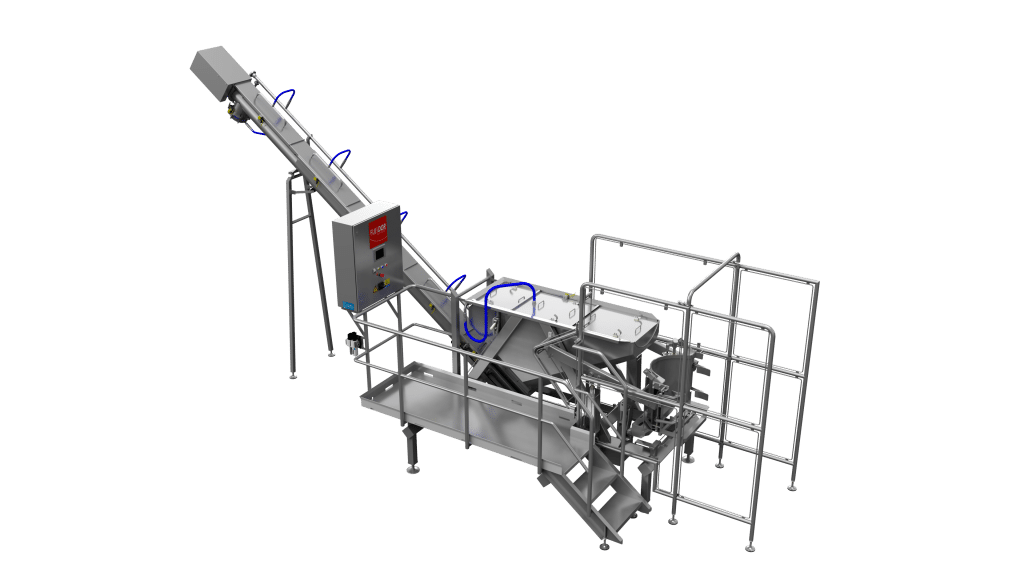

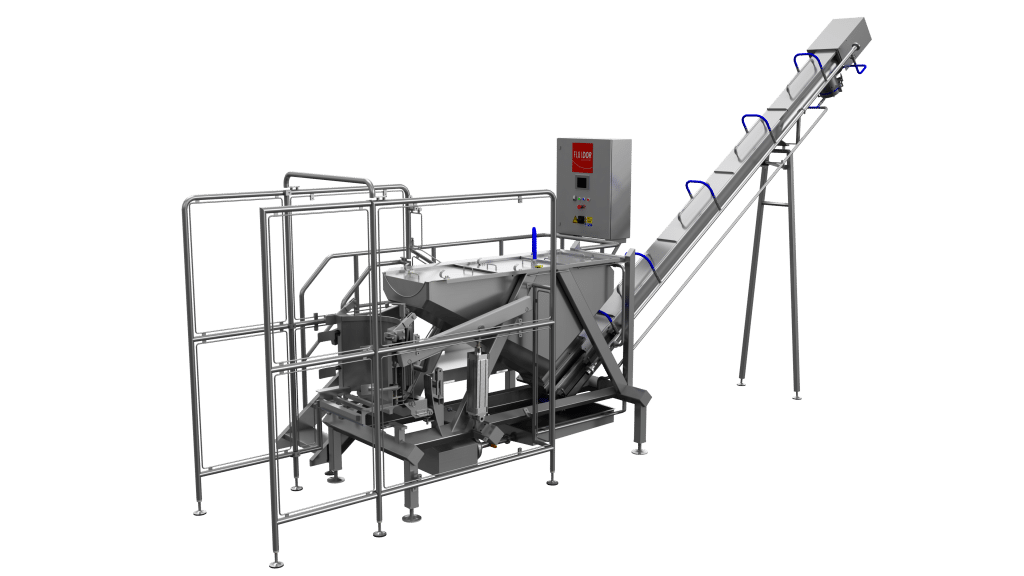

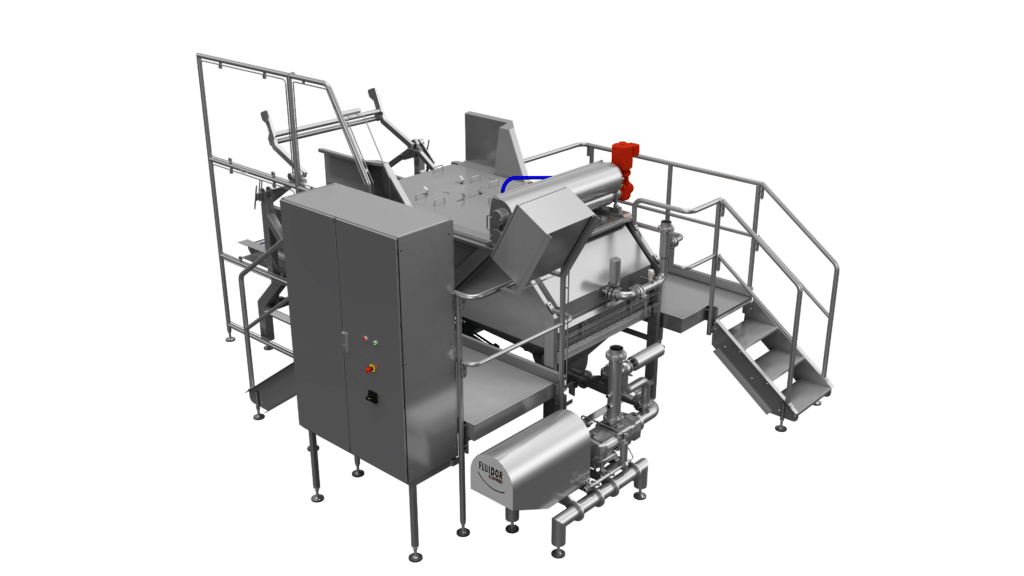

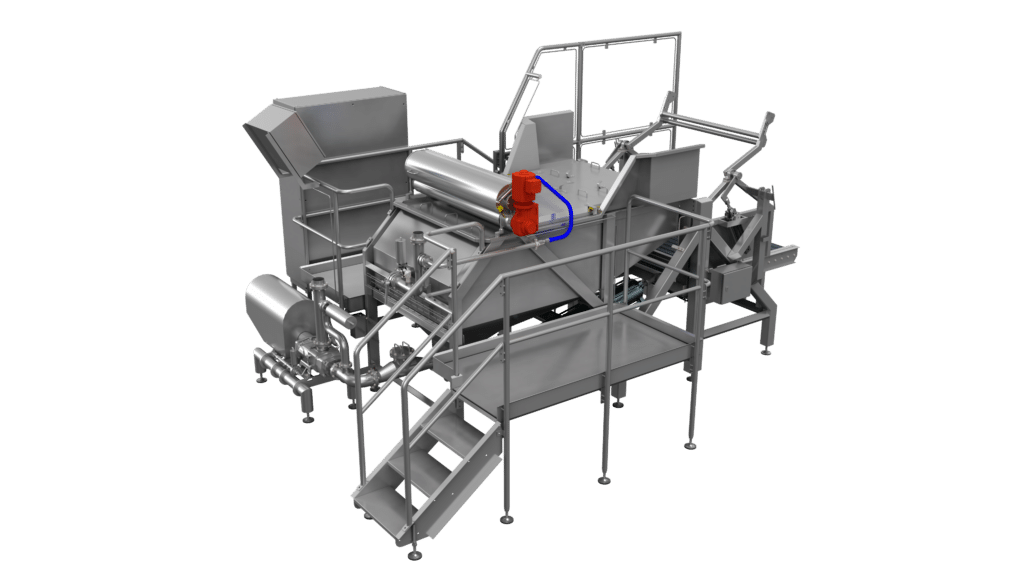

Comments Off on TBDICS

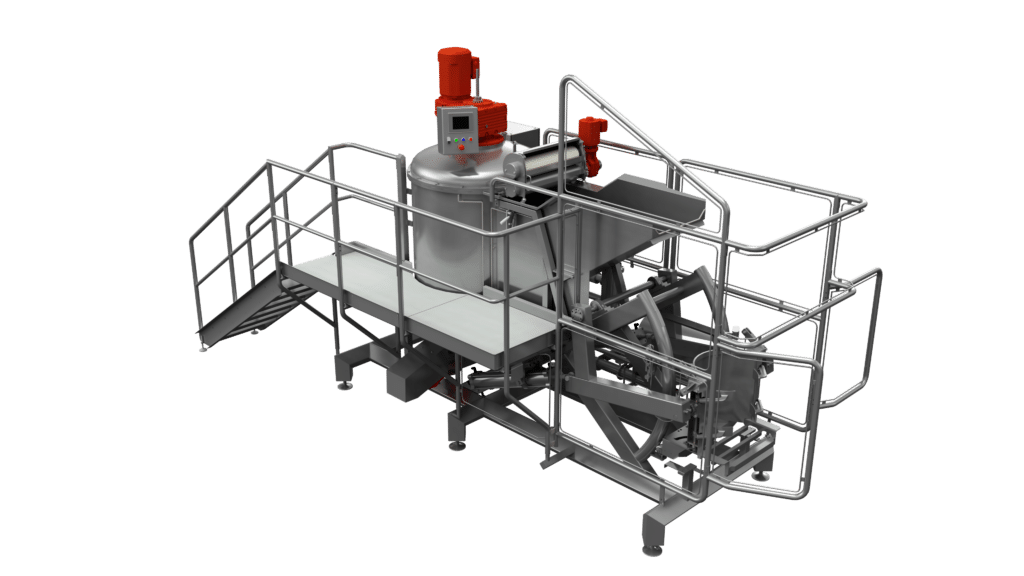

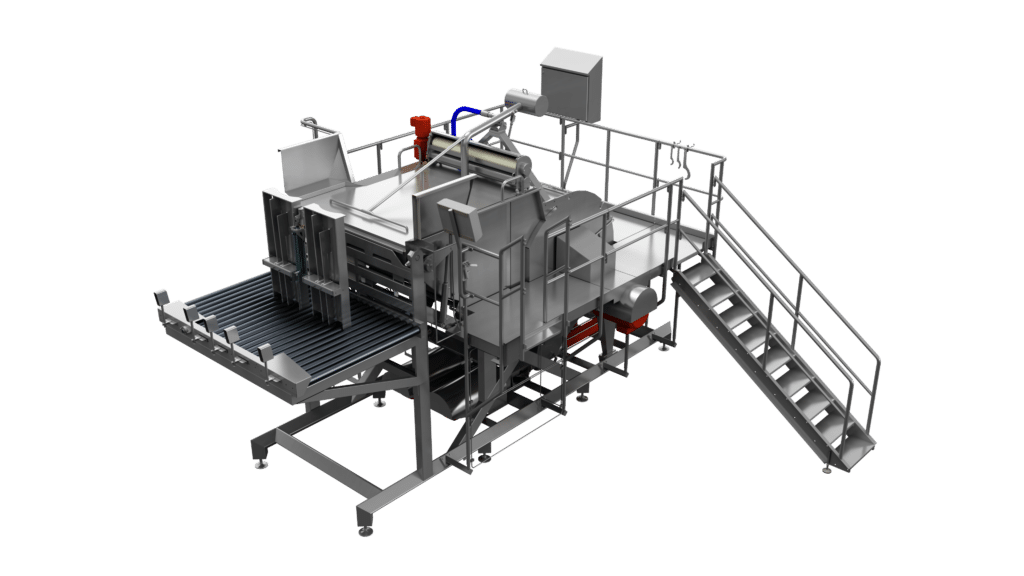

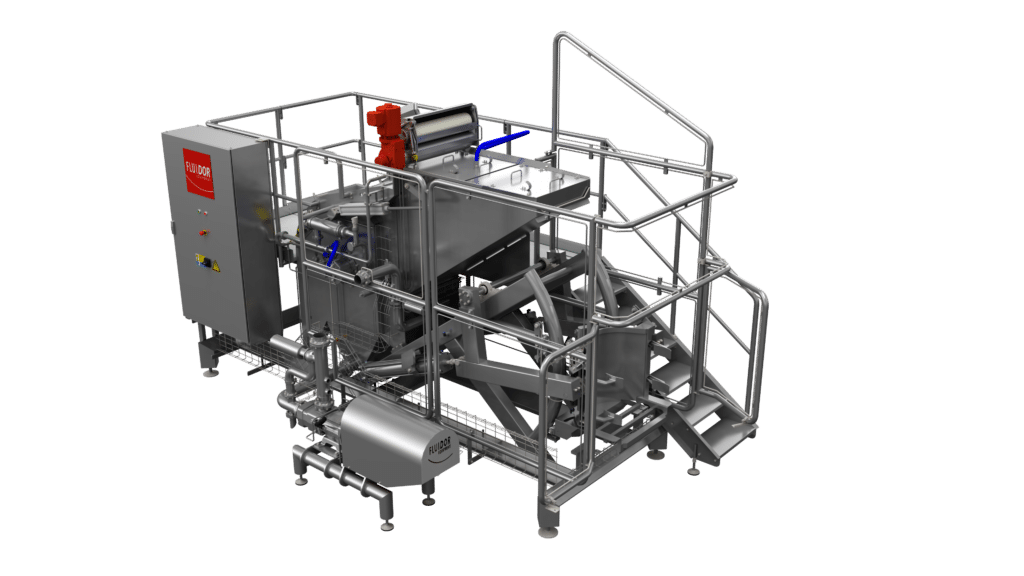

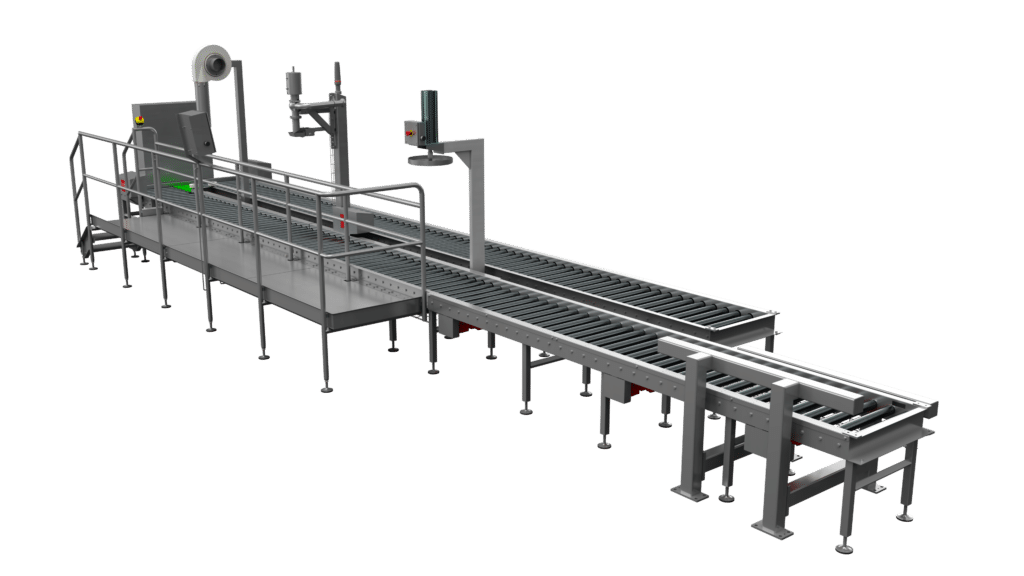

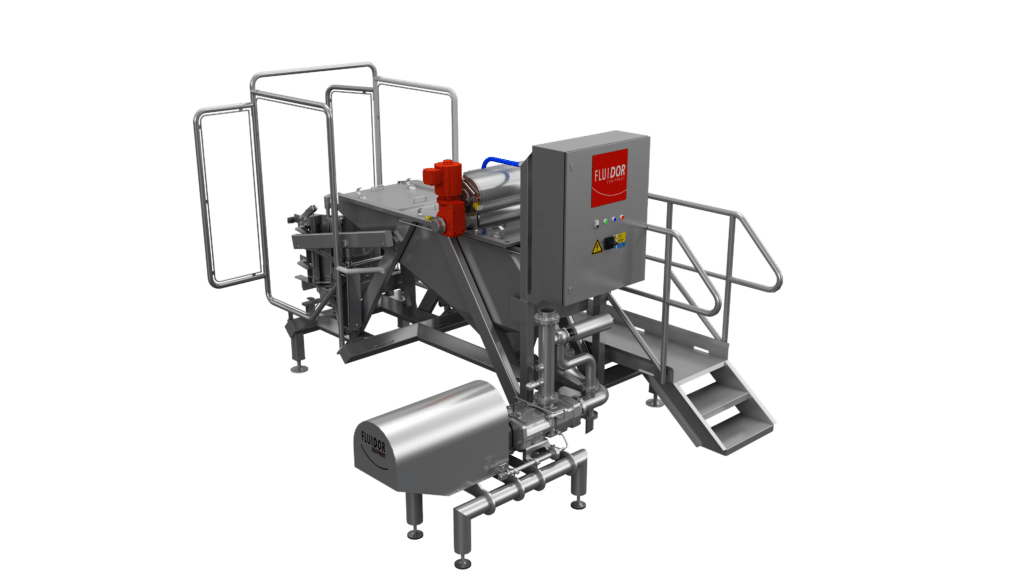

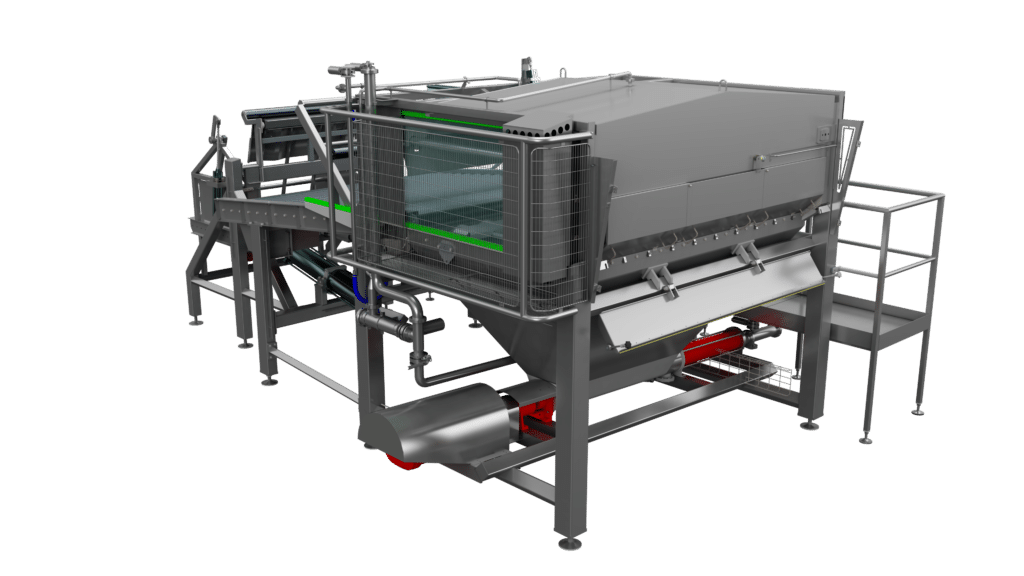

Empty drums and bins with hard frozen product

Does your industry benefit from emptying drums or tote bins with frozen product and crushing it into smaller, manageable flakes for further processing or use?

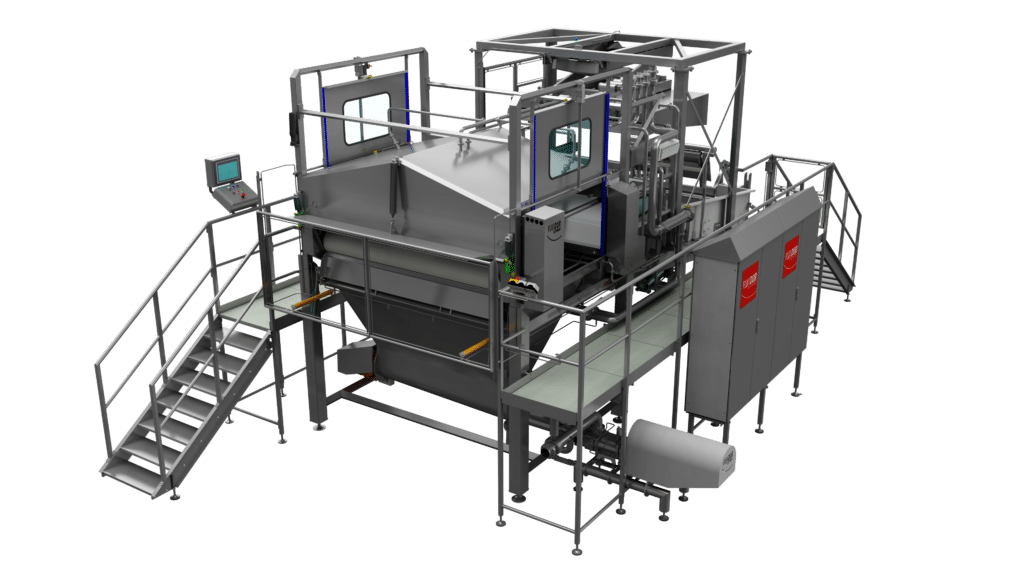

Enhance processing efficiency and improve safety with the Tote-Bin-Dumper-Ice-Crusher (TBDICS) from Fluidor Equipment. Designed for an efficient emptying of open top drums or bins containing products like (hard frozen) fruit juices and fruit juice concentrates.

Juice:

35 bins or 120 drums per hour

Ice:

120 drums per hour* (when used in combination with 2x CIM)

Concentrate:

29 bins or 70 drums/hour

*Without using Bag Squeezer, frozen drums well pre-thawed

How the TBDICS works:

- Per dumping cycle, 2 drums can be emptied. Hard frozen products in drums need to be pre-thawed until the frozen product block is free from the liner and drum.

- After production, the CIP cover can be closed and the twin screw can be used as a CIP circulation pump.

- The drums and bins are placed on the driven pallet roller conveyor system where the lid(s) are removed and liner(s) are opened.

- After opening, the drums and bins are transported in the holder of the TBDICS that can handle all the different types of packages.

- The drums and bins are clamped and lifted by stainless steel hydraulic cylinders and emptied in the hopper.

- The hydraulic operated grid is opened for frozen product and closed for liquid products in bags.

- The operator feeds the bottom part of the liner into the squeezer and the remaining product is squeezed out, reducing the product loss to a bare minimum.

- When dumping hard frozen products, the electric driven crusher with pins crushes the product into flakes.

- At the heated bottom of the hopper, the driven screw conveyor pushes the product into the twin screw product pump.

Efficient

The TBDICS efficiently crushes product from tote bins into smaller, manageable pieces, preventing product loss and saving time.

Safe & easy

The TBDICS is food safe according to the regulations and easy and safe to operate and clean.

Versatile

The TBDICS has several extra options, can be integrated into automated production lines and can be combined with other Fluidor machines.

Wednesday, July 17th, 2024 | Geplaatst in: |

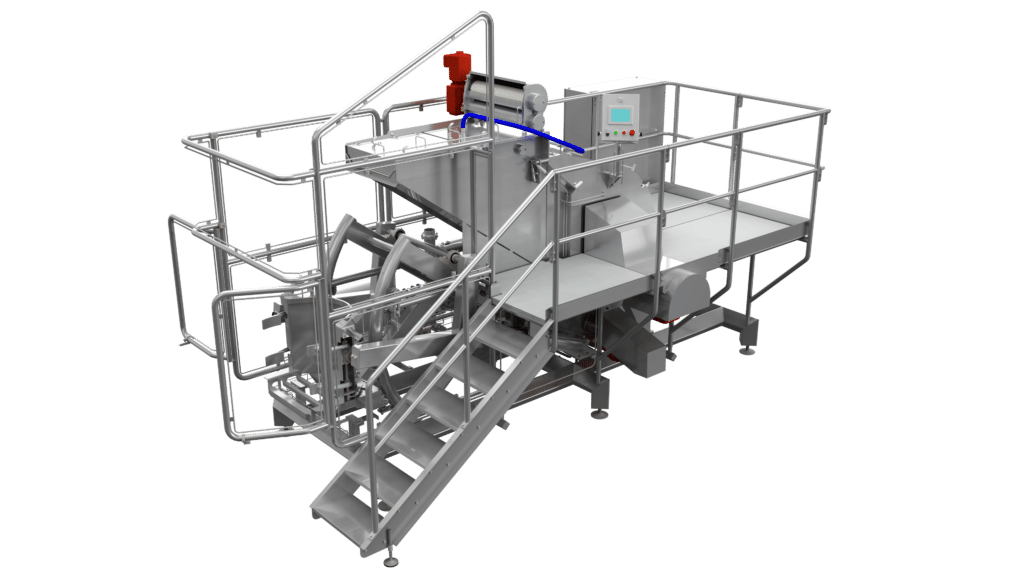

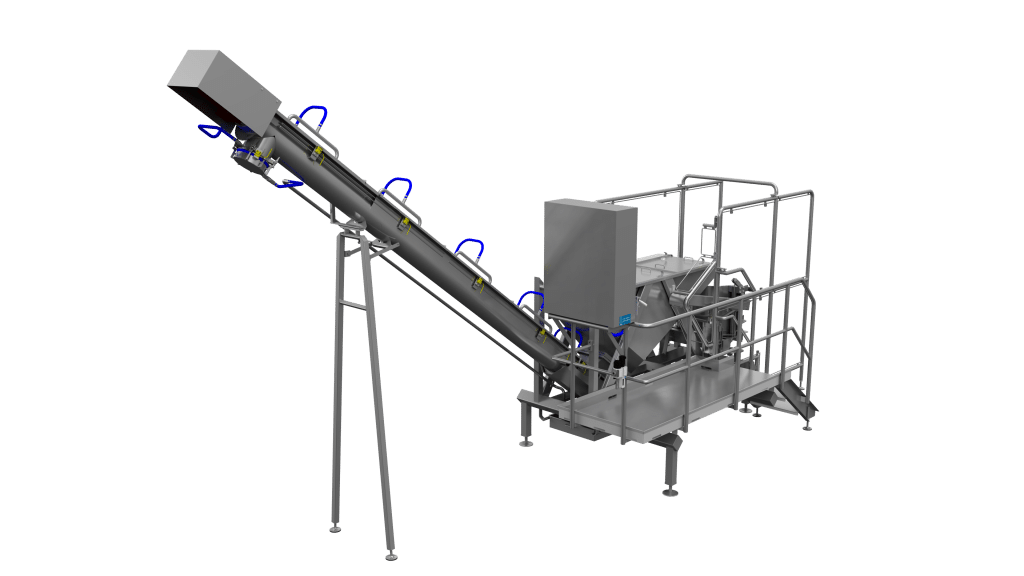

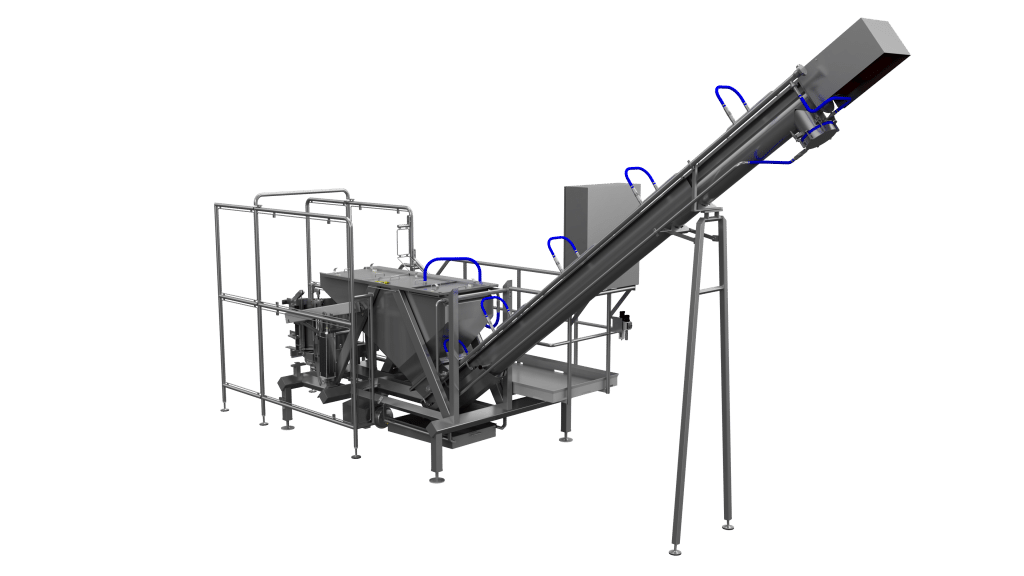

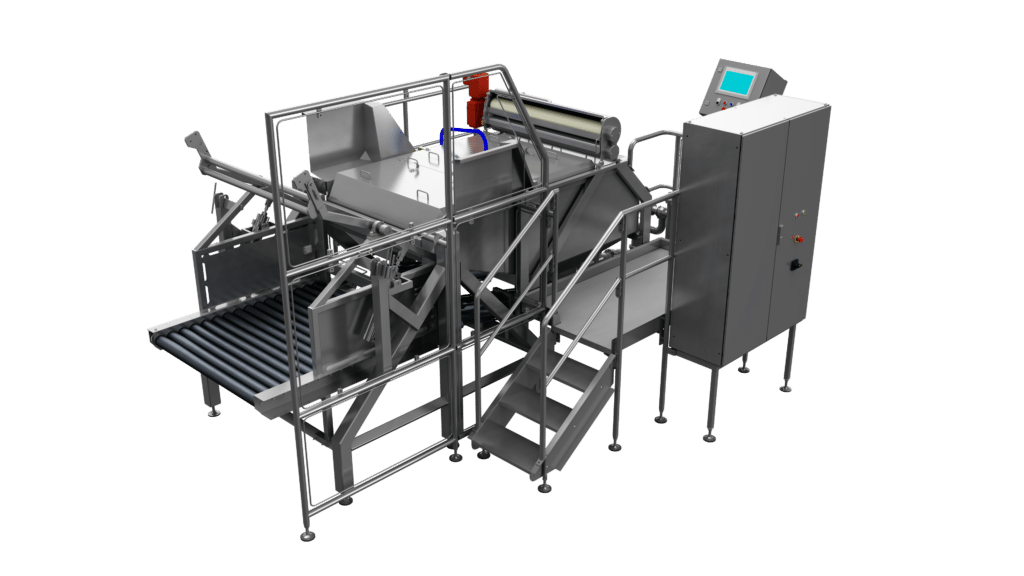

Comments Off on DPRICS

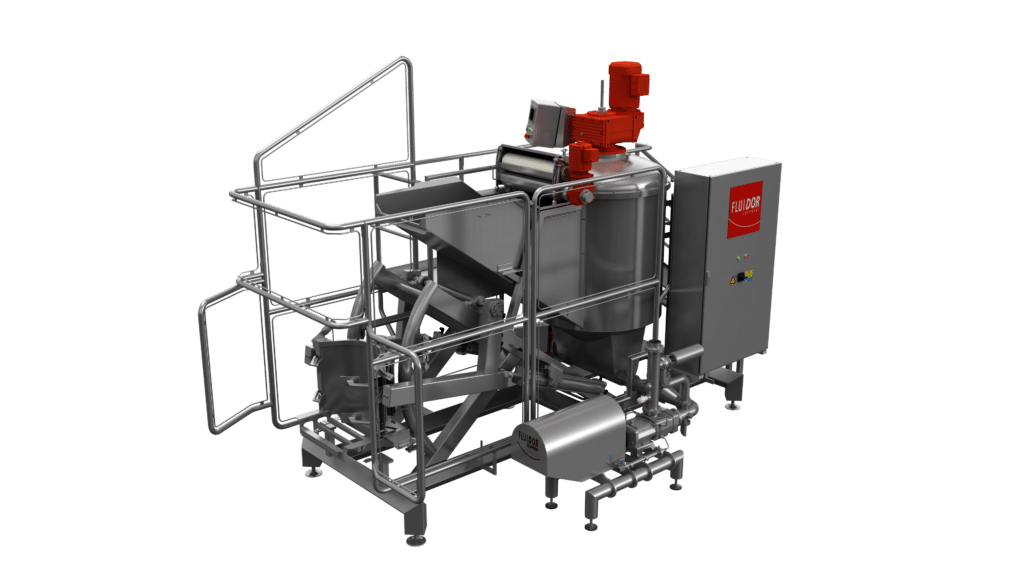

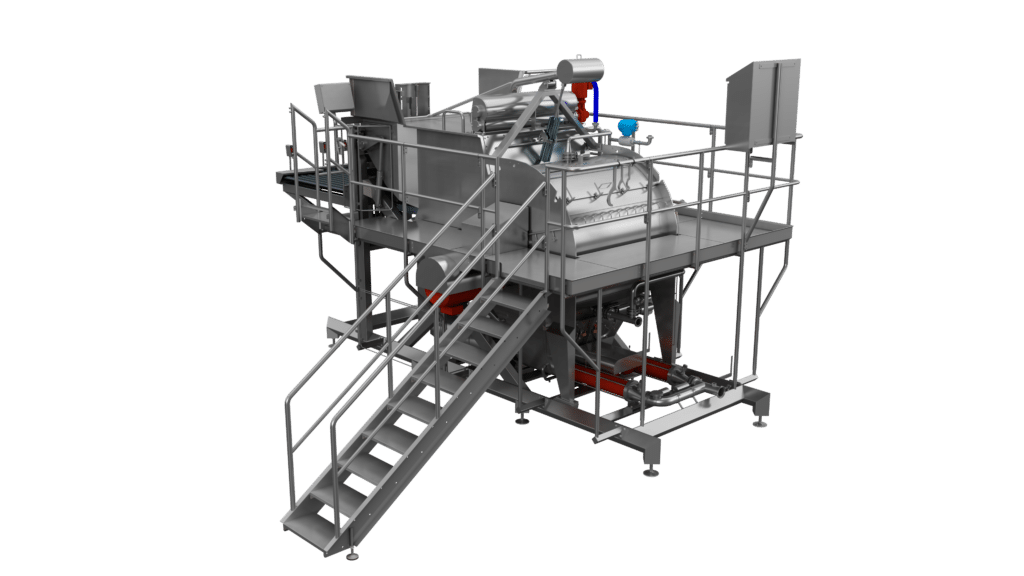

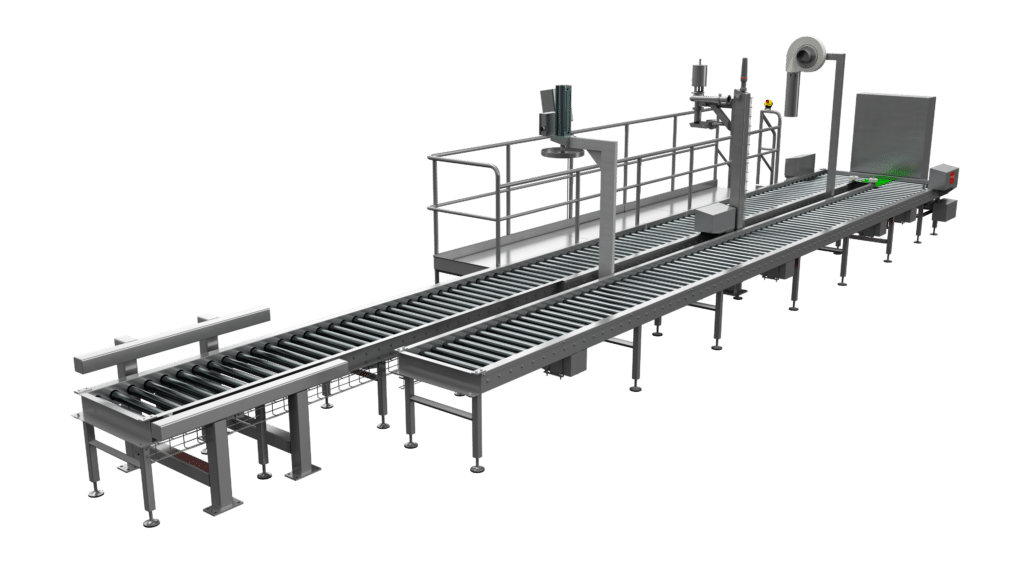

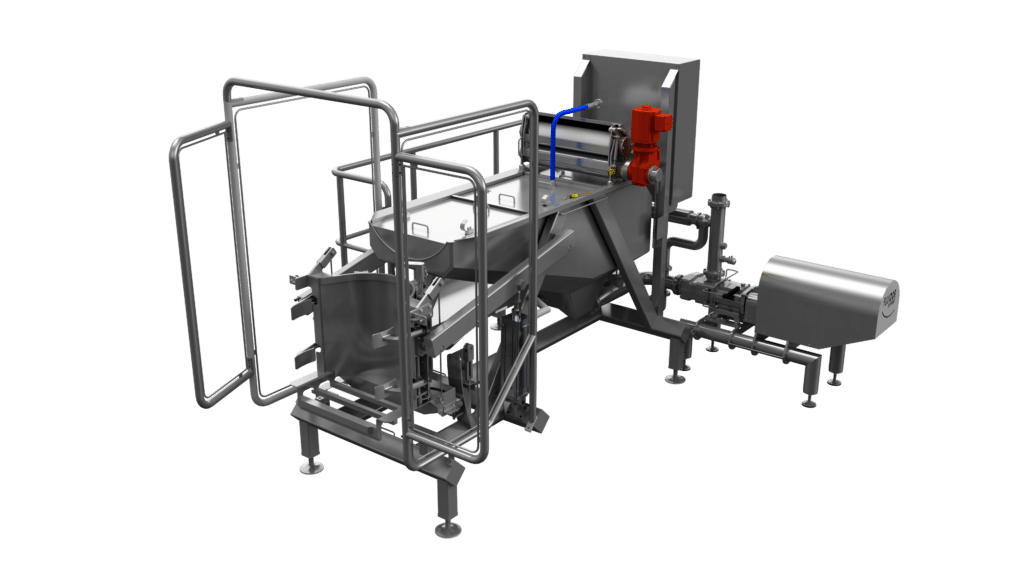

Empty drums with liquid or frozen product in bags

Does your industry benefit from emptying drums with frozen liquid or frozen product and crush it into smaller, manageable flakes for further processing or use?

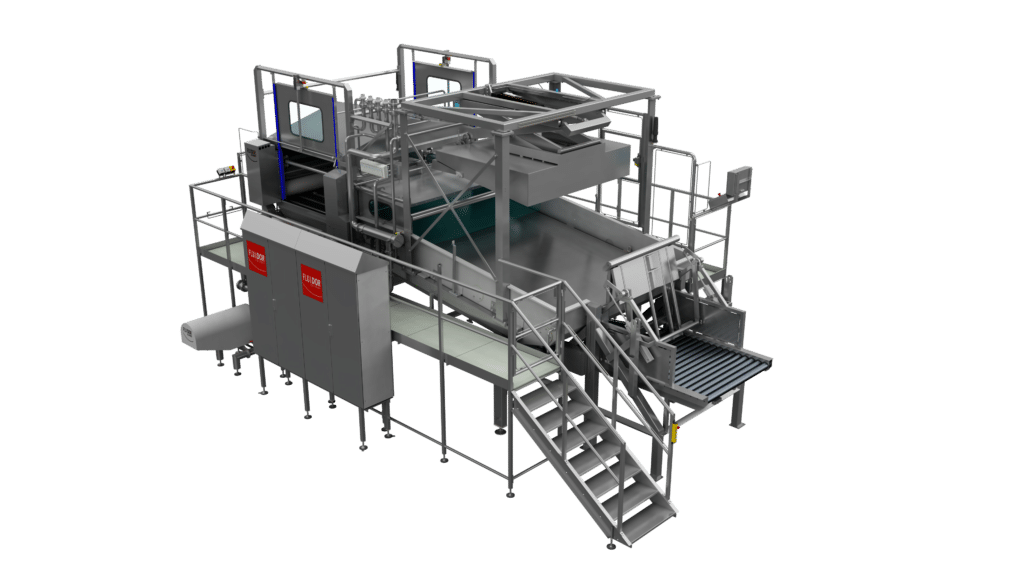

Speed up your process with the Drum Dumper Ice Crusher (DPRICS). Designed for an efficient emptying of drums with liquid or frozen product in bags.

Depending on the infeed and your product, it can handle up to 60 drums per hour.

How the DPRICS works:

- After production, CIP covers are placed and DPRICS can be integrated into your CIP-process.

- The drums are placed on the roller conveyor system by a forklift with a drum gripper.

- The covers are removed and the bag is opened by an operator.

- Drums are centred for correct infeed in the drum holder for pneumatic clamping and lifting.

- The liquid product falls into the hopper and flows towards the product discharge pump.

- The hard frozen product is smoothly guided by a pneumatic safety grid to the driven crusher with pins that crushes it into flakes.

- At the bottom of the hopper, the driven screw conveyor pushes the product into the twin screw product pump.

- The operator feeds the bag into the squeezer, reducing the product loss to a bare minimum.

Efficient

The DPRICS automatically empties drums with liquid or frozen product in bags and crushes it, making it easier to handle and use in other processes and improves efficiency.

Safe & easy

The DPRICS incorporates safety mechanisms to reduce the risk of accidents during operation and improves workplace safety standards.

Automatic

The DPRICS can be integrated into automated production lines, reducing the need for manual labour and enhancing operational efficiency.

Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on FILLING LINE DRUMS

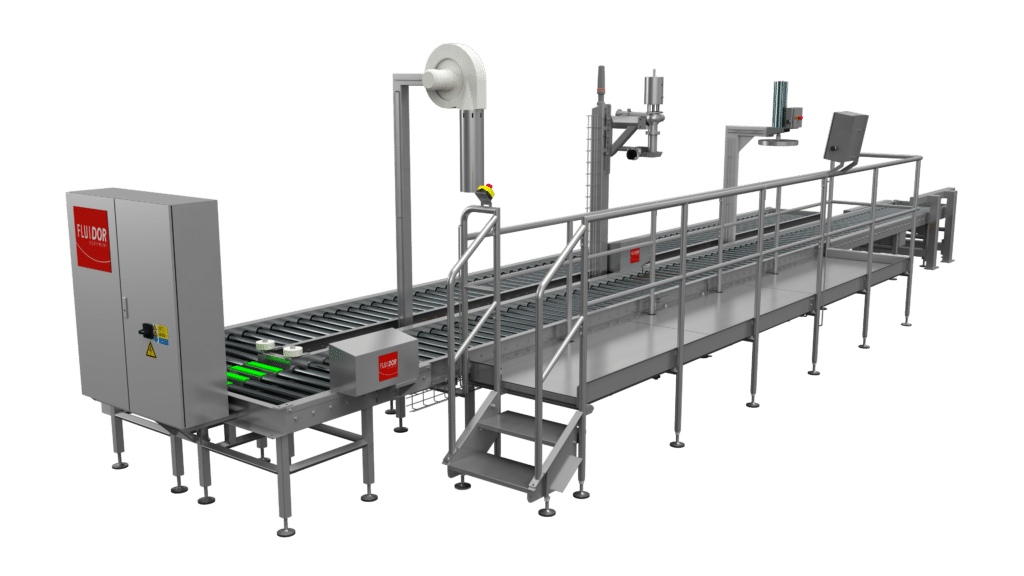

Fill drums precisely and efficiently

Does your industry require precise filling of drums with liquids like fruit juice, for production or storage purposes? The Filling line for drums from Fluidor Equipment is designed to fill your drums safely, efficiently and precisely.

The Filling line for drums is designed for efficient dynamic filling of 200 litre drums with fruit juices, fruit juice concentrates or blends with a viscosity up to 15.000 cP. Depending on the infeed and your product, it can handle up to 60 drums per hour.

You can obtain several data out of the control system. Please discuss in detail what data you expect, prior to installation of the equipment.

How the Filling line works:

A complete Drum Filling Line consists out of following process steps:

- Station for insertion of plastic bags or liners by means of a Bagblower.

- Drum Filling Station on load cells with Filling Lance.

- Stop position for closing of bags/liners.

- Drum lid press for closing of drum.

- Pneumatic driven sliding doors to enter/exit a Clean Room.

This is how the Filling line works:

- Full drums leave the Clean Room through a pneumatic driven sliding door.

- Empty drums are loaded onto a driven roller conveyor, enter the Clean Room and stop at position for manual insertion of plastic liner(s) by means of a Bagblower. The Bagblower is an electric driven air blower, executed with an air filter for clean air inside bags/liners.

- Drum with liner will be conveyed to the filling position, where the drum is positioned on a roller conveyor section equipped with 4 load cells to control the weight of the product to be loaded.

- The Filling Lance lowers by means of a frequency controlled electric motor into the drum and starts loading at full flow. The position of the Filling Lance is automatically controlled by the load cells and frequency drive to prevent foaming of the product. The last part of loading is at low flow to achieve an accuracy of 0,5 kg.

- Drum with product will be conveyed to next stop position for manual closing of liners, finally the drum will stop at the Drum Closing Station, where an operator positions the drum lid properly by means of a pneumatic press and secures the clamping ring by a pneumatic nut spanner.

Precise

The filling line for drums guarantees accurate filling to exact specifications. So you can maintain your product quality and consistency and reduce errors in production.

Efficient

The filling line automates the filling process, improves throughput and reduces labour costs. Enhance your operational efficiency and productivity.

Flexible and versatile

The filling line for drums handles various drum sizes and types. Adapt it to your different production needs.

Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on DAPS-SPECIAL

Empty drums safely, efficiently and quickly

Does your industry work with liquids that contain pieces, like fruit juice? The Drum Dumper DAPS Special from Fluidor Equipment is especially designed to empty your drums safely, efficiently and quickly.

The Drum Dumper (DAPS Special) is designed for an efficient emptying of 200 litre open top drums, containing liquid products like fruit juice with fruit pieces.

This machine was developed especially for “RANI”-products.

Depending on the infeed and your product, it can handle up to 4 m³/h (600 kg/m³) fruit pieces per hour.

How the DAPS Special works:

- After production, CIP covers can be placed for integration into your CIP process.

- Drums are placed on the roller conveyor section. At (optional) Drum Opening Station, lid will be removed and liner(s) will be opened.

- The drum is lifted and tipped pneumatically, product will fall into the collecting hopper, flow into the hopper and is fed to a screw conveyor for separation of the fruit pieces (pulp) and the fruit juice.

- The fruit pieces are discharged from the top of the screw conveyor for next process steps.

- The fruit juice is collected and pumped by a centrifugal pump to the next process step.

Efficient

The DAPS Special ensures fast and complete emptying of drums, which enhances productivity by saving time in your production process.

Safe & easy

The DAPS Special minimises the risk of spills and accidents, for a safer work environment.

Cost reduction

The DAPS Special integrates with automated production lines and is designed for complete drum emptying. Reduce labour costs, minimise material waste and decrease maintenance expenses.

Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on TBD-FLUIDS

Empty tote bins and drums efficiently

Does your industry work with liquids stored in containers and do you want to transfer these liquids to production processes or other storage facilities? The Tote Bin Dumper-Fluids from Fluidor Equipment empties your tote bins and drums quickly, efficiently and safely.

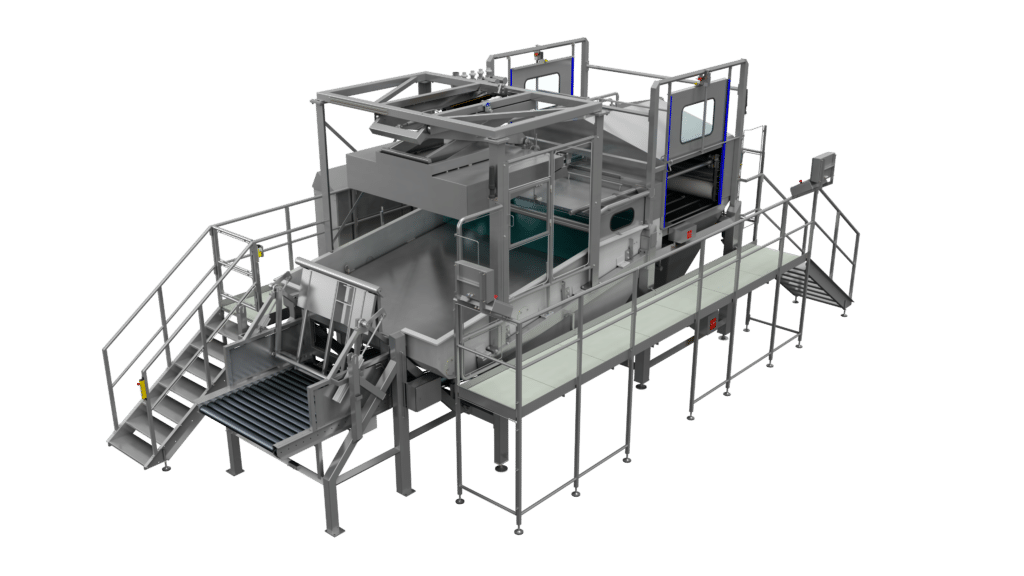

The TBD-Fluids is designed for an efficient emptying of tote bins and drums with liquid product in aseptic bags, like fruit juices and concentrates or other liquids up to 70°. Depending on the bin / drum infeed and your product, it can handle 20 tote bins or 40 drums per hour (2 drums per cycle).

How the TBD-Fluids works:

- After production, CIP covers are placed and TBD-Fluids can be integrated into your CIP-process.

- The tote bins or drums are placed on the roller conveyor system by fork lift truck.

- The covers are removed and the bag is opened by an operator.

- Bins and drums are centred for correct infeed in the bin/drum holder for pneumatic lifting / dumping.

- The bag falls on the grid and the product flows towards the product discharge pump.

- Operator feeds the bag into the squeezer, reducing the product loss to a bare minimum.

Efficient

The TBD-Fluids empties tote bins and drums fast and consistent, which increases production throughput and saves time.

Safe & easy

The TBD-Fluids minimises the risk of spills and accidents, reducing manual lifting and tilting. For a safer work environment and less physical strain on workers.

Cost reduction

The TBD-Fluids automates and integrates into your production lines, designed to completely empty containers. That results in lower labour costs, less material waste and lower maintenance expenses.

Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on DAPS

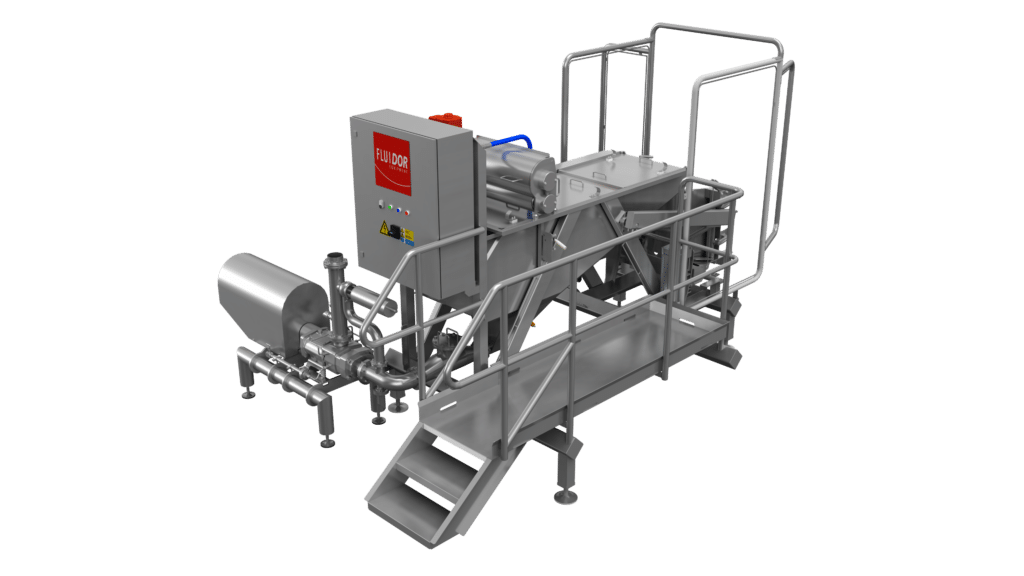

Empty drums quickly, efficiently and safely

Does your industry need to transfer liquids from drums to a production process or other storage containers? The Drum Dumper (DAPS) from Fluidor Equipment empties your drums quickly, efficiently and safely.

This machine is designed for an efficient emptying of 200 litre open top drums containing liquid products like fruit juice concentrates (up to 70° brix), with a maximum viscosity of up to 20.000 cP.

How the DAPS works:

- After production, CIP covers with rotating nozzle can be placed for integration into your CIP process.

- Drums are placed on the roller conveyor section, at (optional) the drum opening station the lid is removed and the liner(s) are opened.

- The drums are transported to the Drum Dumper, where the drums are lifted and tilted pneumatically.

- The liner with product falls into the collection hopper and is stopped by a grid. The liner will partially empty itself.

- The operator inserts the lower part of the liner into the squeezer and the remaining product is squeezed out.

- The product flows into the product hopper and is discharged by a twin-screw pump.

Cost-efficient

The DAPS is designed to empty the entire drum, which minimises raw material waste. It also ensures fast and consistent emptying of drums, helping to save production time and increase productivity.

Safe & easy

The DAPS minimises the risk of spills and accidents, which contributes to a safe working environment. It also reduces the physical burden on employees, as manual lifting and tilting is no longer necessary.

Flexible and durable

The DAPS Drum Dumper is built to last and requires minimal maintenance. The machine can handle different sizes and types of drums, making it widely applicable in various industries.

Wednesday, July 17th, 2024 | Geplaatst in: |

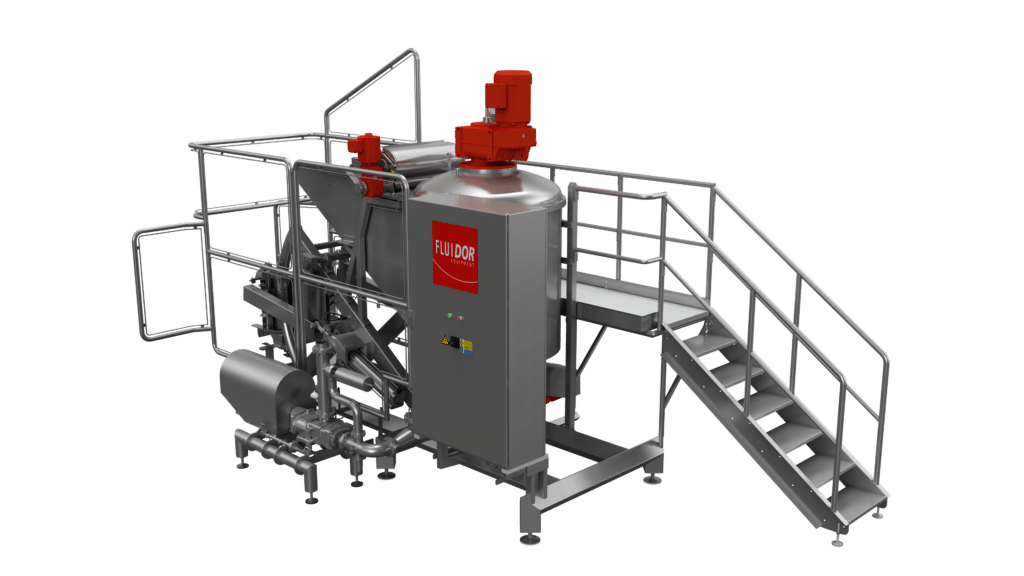

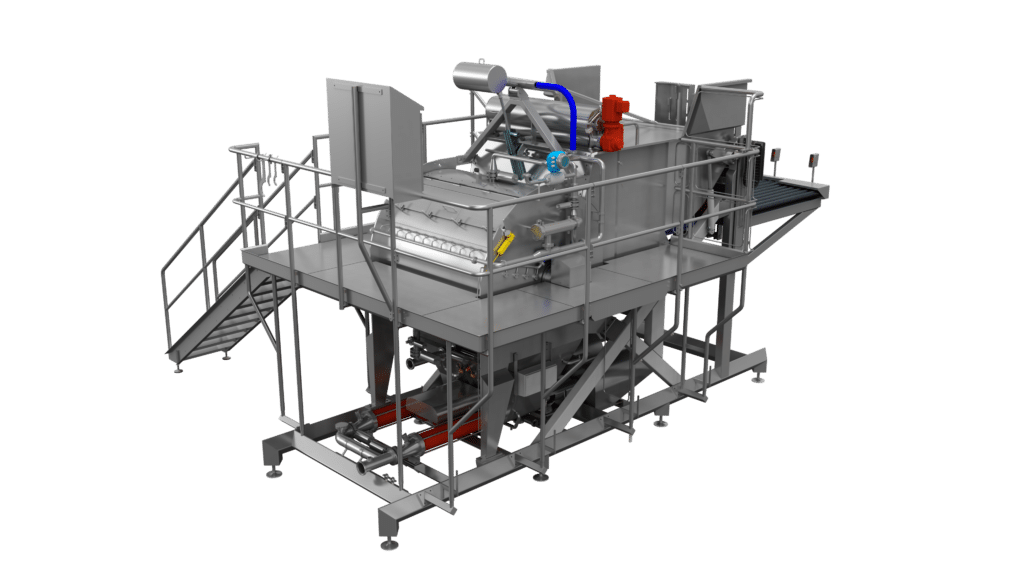

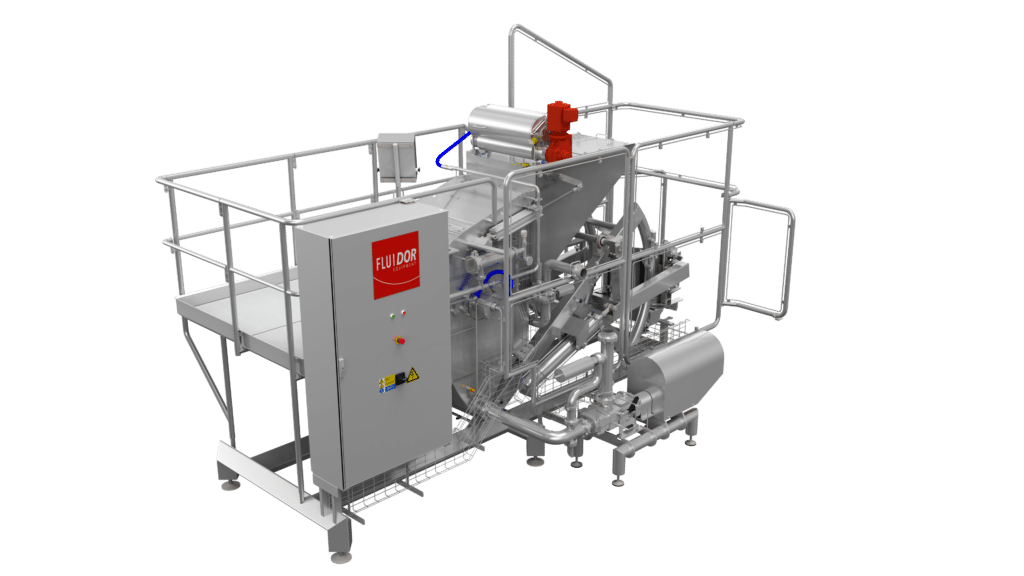

Comments Off on TBD-PASTE

Empty tote bins and drums safely and efficiently

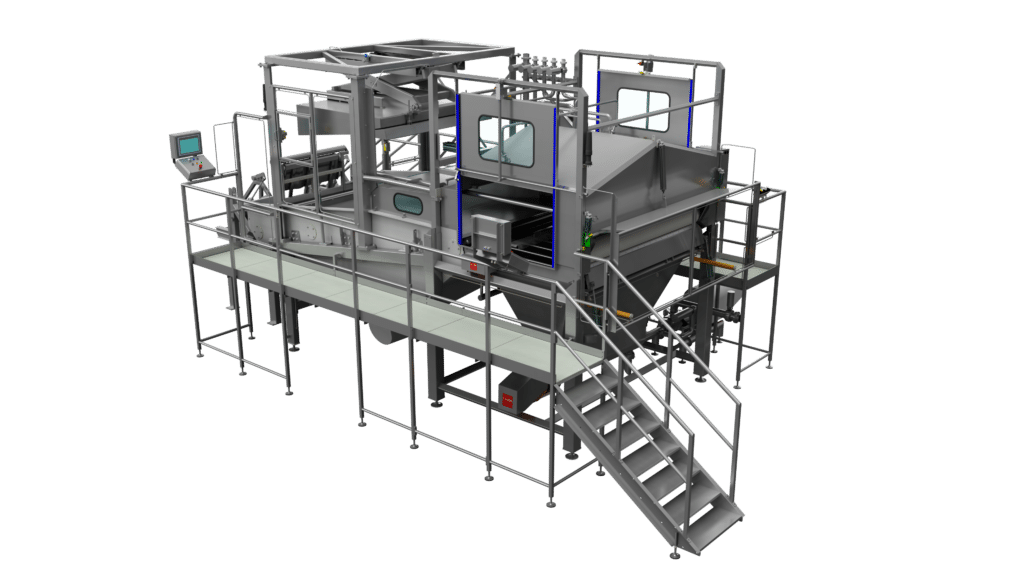

Does your industry require emptying tote bins and drums with thick materials like pastes? The Tote Bin Dumper Paste (TBD-Paste) from Fluidor Equipment is designed for automatic emptying of tote bins and drums with aseptically packed viscous products like Cold Break, Hot Break or Super Hot Break Tomato paste (with press plate).

Depending on the infeed and your product, it can handle up to 20 tote bins or 20 drums per hour.

How the TBD-Paste works:

- The bins or drums are transported into the roller conveyor section of the bin/drum holder.

- The bin/drum is clamped and lifted by pneumatic cylinders. At the highest tilting point, the aseptic bag falls out of the bin/drum and spreads out on a stainless steel wire belt.

- The electric driven press plate lowers and flattens the aseptic bag (option for Super Hot Break).

- The wire belt transports the closed aseptic bag through the washing tunnel, provided with a set of spray-nozzles to clean all sides of the bag with high pressure. The cleaning water is collected and drained.

- Above the product hopper, the aseptic bag is automatically grabbed by the bag squeezer. A pneumatic cylinder pulls the bag squeezer over the driven knives that cut the bag open at the bottom side and the tomato paste flows into the product hopper.

- The aseptic bag is emptied completely by the bag squeezer, reducing the loss to a bare minimum (<0,1%). The empty bags are collected in a waste container at the outlet side of the machine (not in scope of supply).

- At the bottom of the hopper, a driven screw conveyor pushes the product into the external twin screw product pump for the next process step.

- After production and short manual pre-cleaning, the C.I.P. covers can be closed and the C.I.P. cleaning with an integrated set of nozzles can be started.

Due to variation in quality (hardness) of the poly liner filler caps, which cannot be influenced by Fluidor and can differ per (bag)supplier, there is a possibility that filler caps from certain bags can break during squeezing, which may lead to pieces of plastic ending up in the product. Fluidor offers a solution for this with transfer caps.

Versatile

The TBD-Paste is versatile, capable of handling a wide range of paste-like substances across various industries.

Safe & easy

The TBD-Paste improves workplace safety by minimising the risks associated with manual handling, ensuring a safer environment for operators.

Productive

The TBD-Paste enhances operational efficiency by automating processes for handling and transferring paste-like materials.

Wednesday, July 17th, 2024 | Geplaatst in: |

Comments Off on TBD-PASTE LTD

Empty tote bins and drums safely and efficiently

Does your industry require emptying tote bins and drums with thick materials like pastes? The Tote Bin Dumper Paste Limited (TBD-Paste LTD) from Fluidor Equipment is designed for automatic emptying of tote bins and drums with aseptically packed viscous products, like Cold Break and most Hot Break Tomato paste.

Depending on the infeed and your product, it can handle up to 20 tote bins or 20 drums per hour.

How the TBD-Paste LTD works:

- The bins or drums are transported into the roller conveyor section of the bin/drum holder.

- The bin/drum is clamped and lifted by pneumatic cylinders. At the highest tilting point, the aseptic bag falls out of the bin/drum and spreads out on a conveyor of tubular rollers.

- The conveyor transports the closed aseptic bag through the washing tunnel, provided with a set of spray-nozzles to clean all sides of the bag with high pressure.

- Above the product hopper, the aseptic bag is automatically grabbed by the bag squeezer. A pneumatic cylinder pulls the bag squeezer over the driven knives that cut the bag open at the bottom side and the tomato paste flows into the product hopper.

- The aseptic bag is emptied completely by the bag squeezer, reducing the loss to a bare minimum (<0,1%). The empty bags are collected in a waste container at the outlet side of the machine (not in scope of supply).

- At the bottom of the hopper, a driven screw conveyor pushes the product into the external twin screw product pump for the next process step.

- After production and short manual pre-cleaning, the C.I.P. covers can be closed and the C.I.P. cleaning with an integrated set of nozzles can be started.

Due to variation in quality (hardness) of the poly liner filler caps, which cannot be influenced by Fluidor and can differ per (bag)supplier, there is a possibility that filler caps from certain bags can break during squeezing, which may lead to pieces of plastic ending up in the product. Fluidor offers a solution for this with transfer caps.

Efficient

The TBD-Paste LTD streamlines the emptying process, reducing manual labour and operational time significantly.

Safe & easy

By automating the dumping process, the TBD-Paste LTD minimises the risk of injuries associated with manual handling of heavy tote bins.

Productive

Operators can focus on other tasks, while the TBD-Paste LTD handles the repetitive and physically demanding task of emptying tote bins.