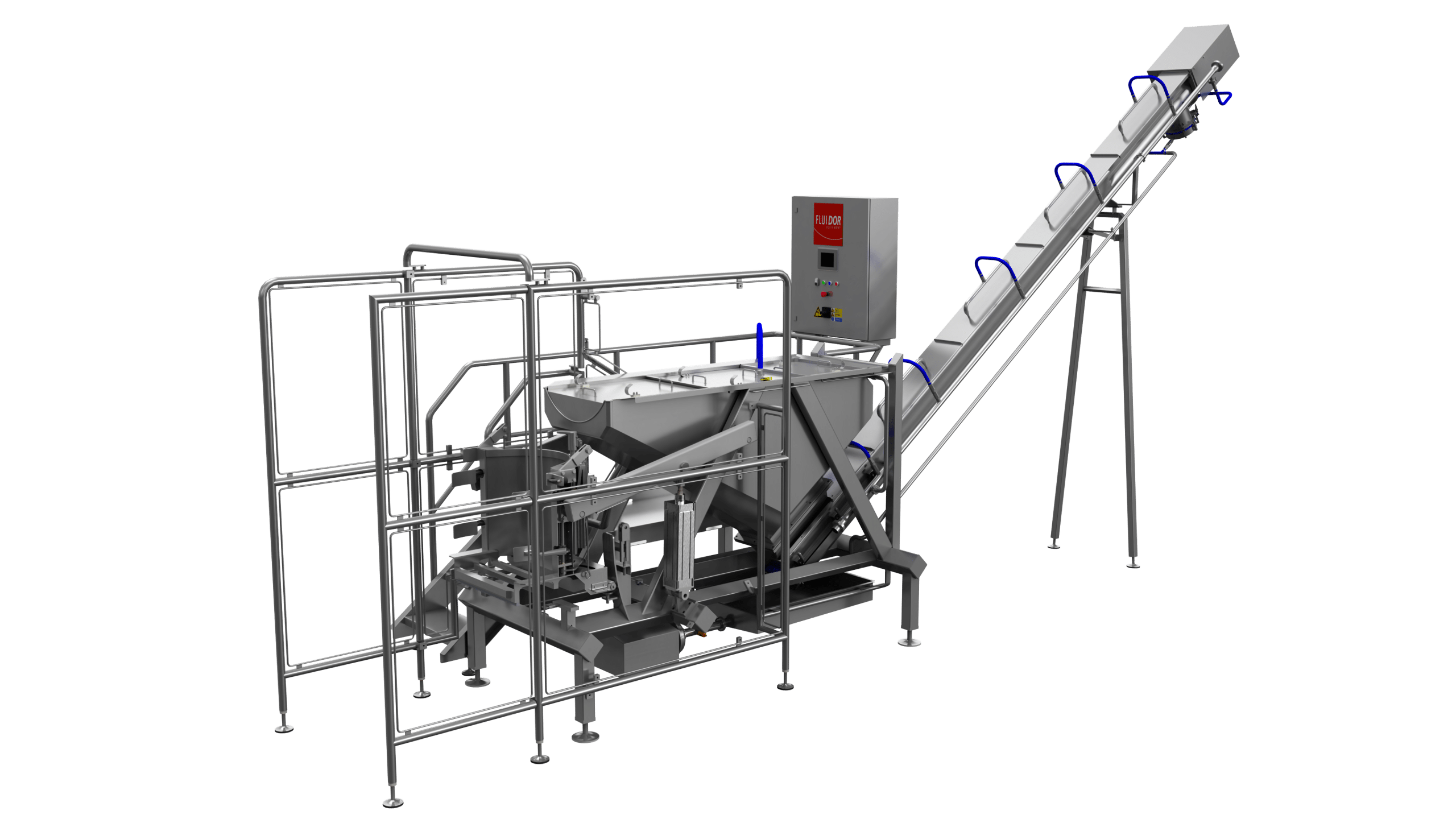

FLUIVAC

With FLUIVAC, you save valuable utilities and turn valueless waste into sellable product. More efficiency, less waste.

Empty liquid and viscous products from process lines

Does your industry wish to recover valuable product and minimise waste?

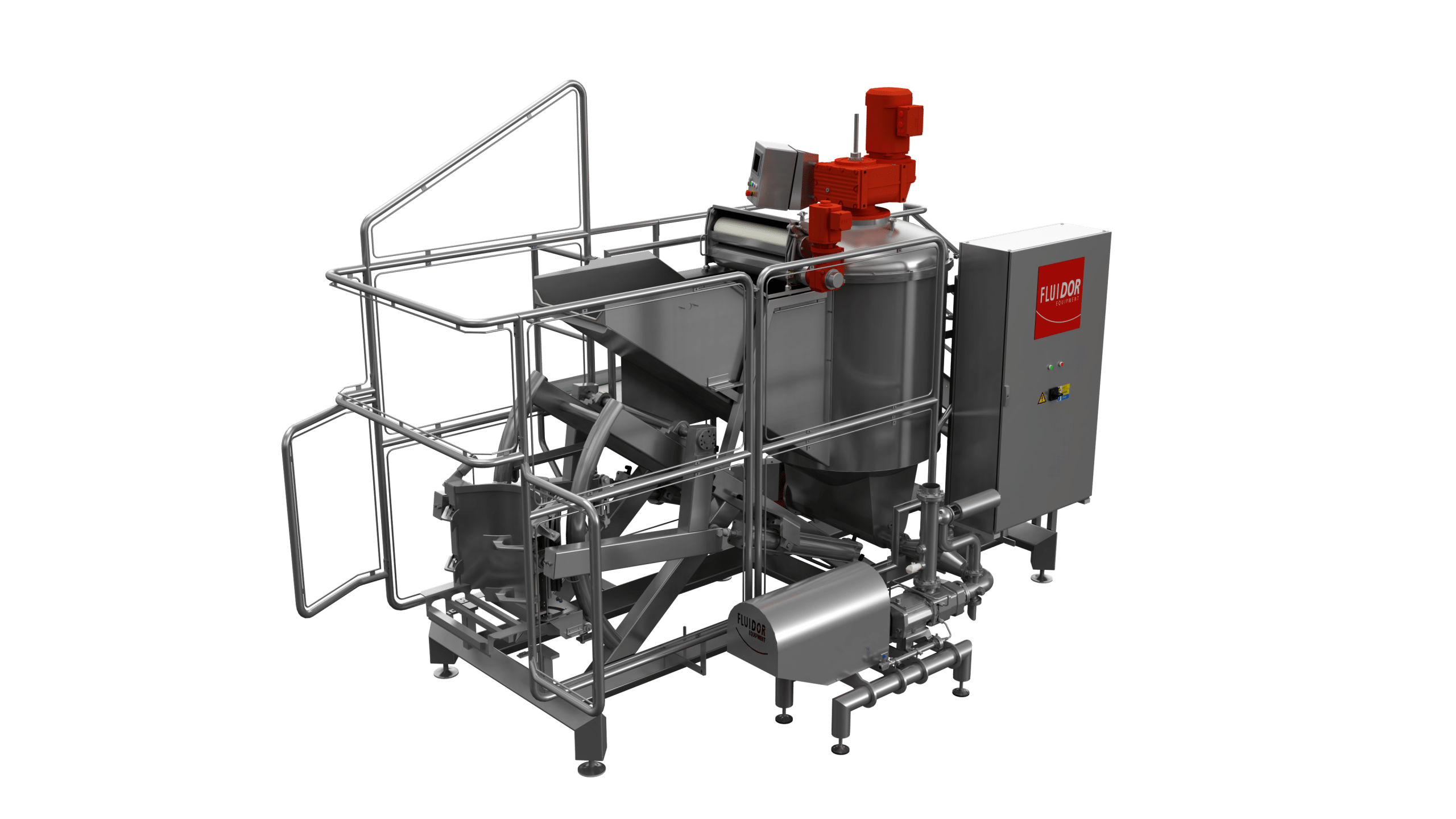

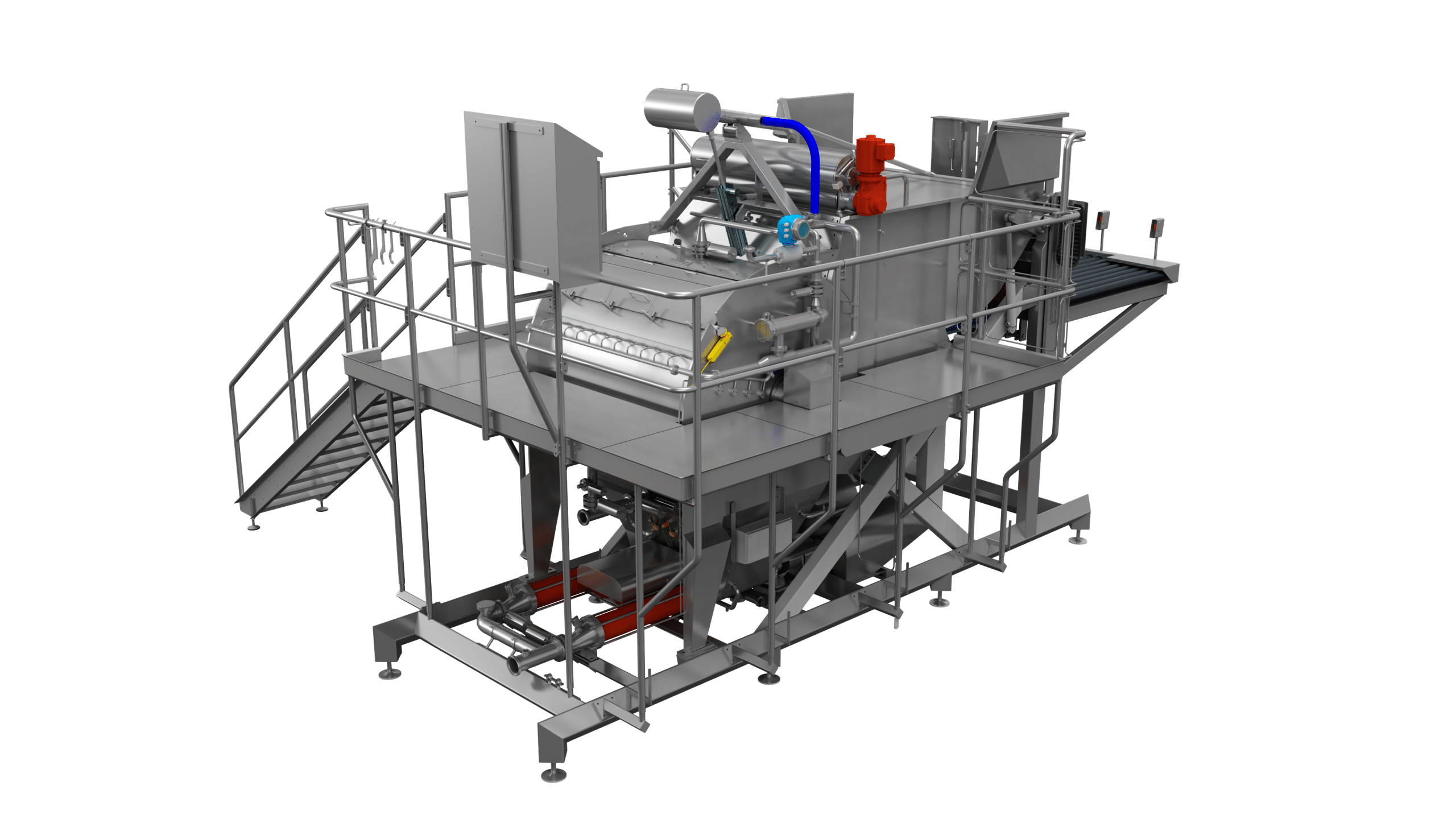

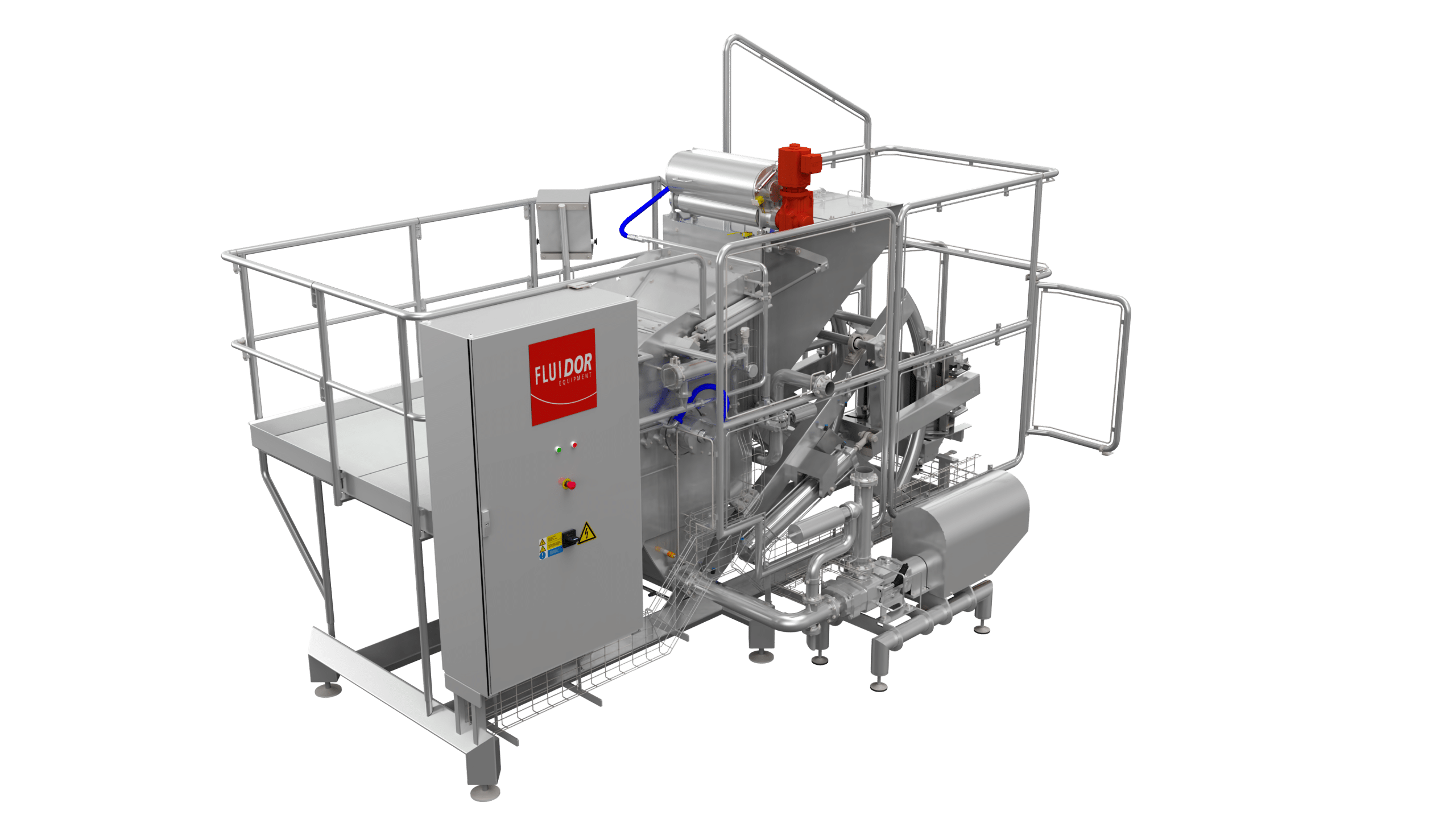

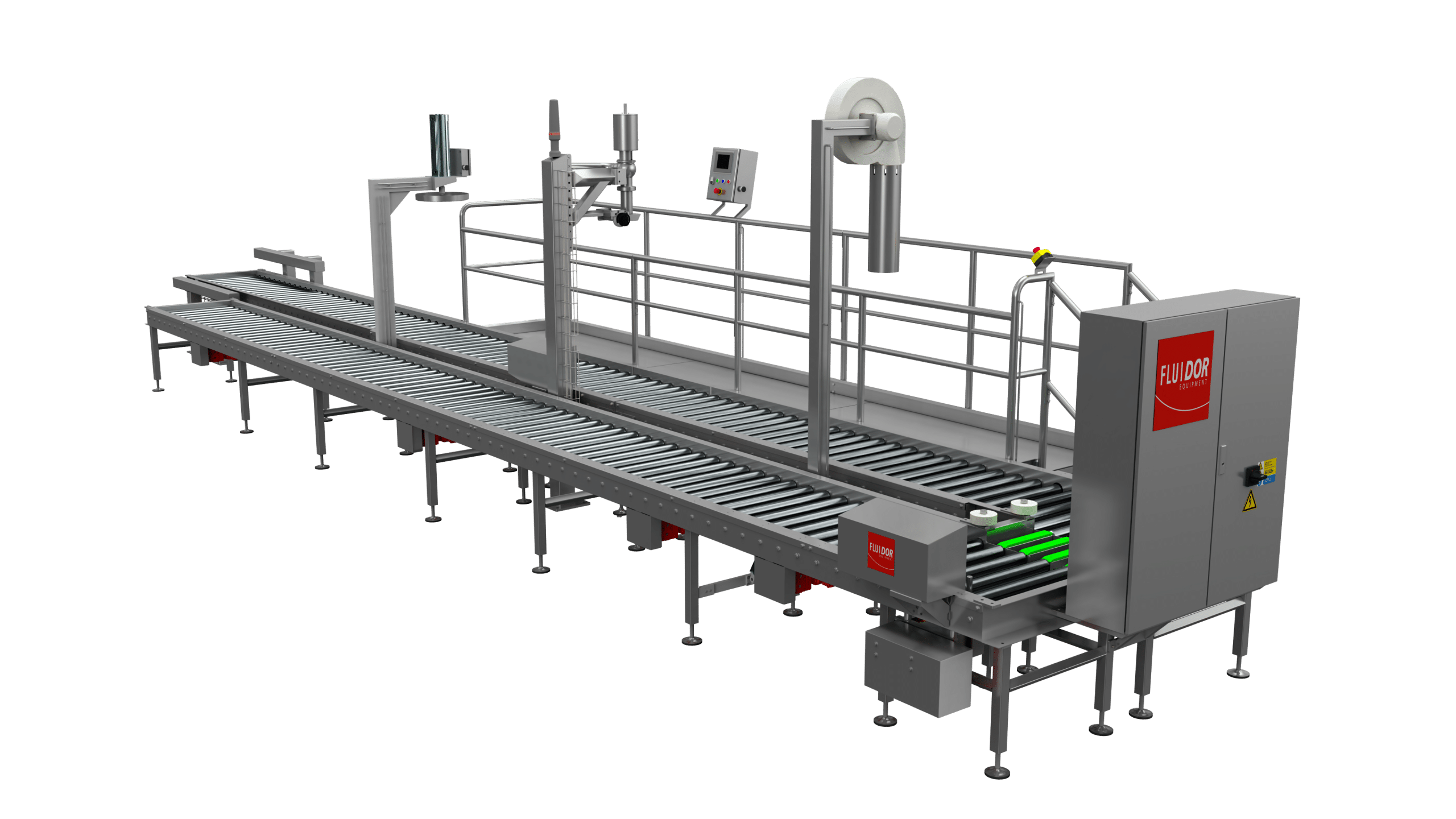

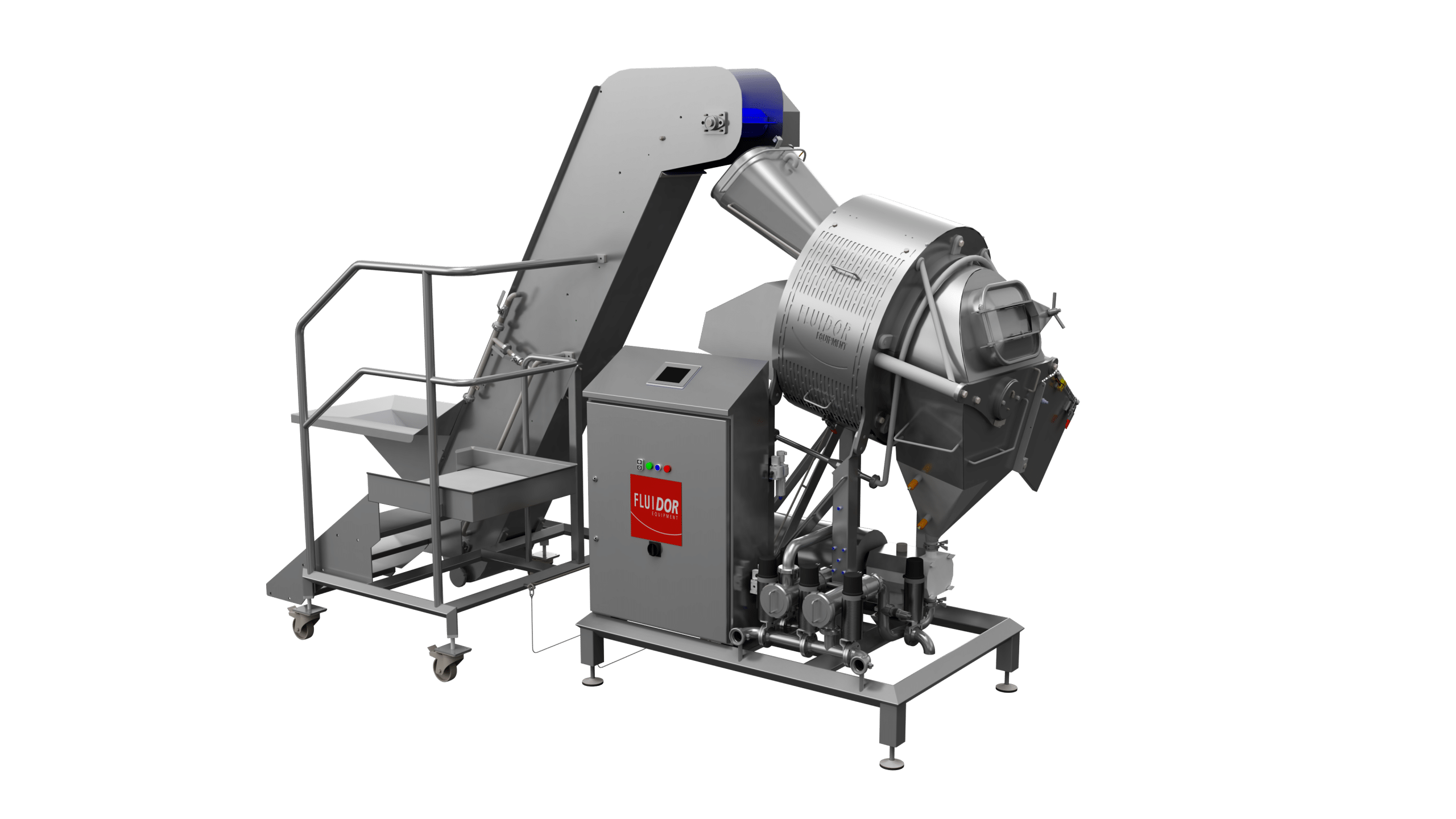

FLUIVAC from Fluidor Equipment is designed for efficient emptying of liquid and viscous products from process lines up to 100mm. The system can automatically clear up to 300 different production and CIP process lines by programmed recipes.

This innovative, patented system recovers and saves valuable utilities and turns waste into sellable product. Integrate FLUIVAC into your production process and save up to 98% of usable product that’s left in your pipes and components.

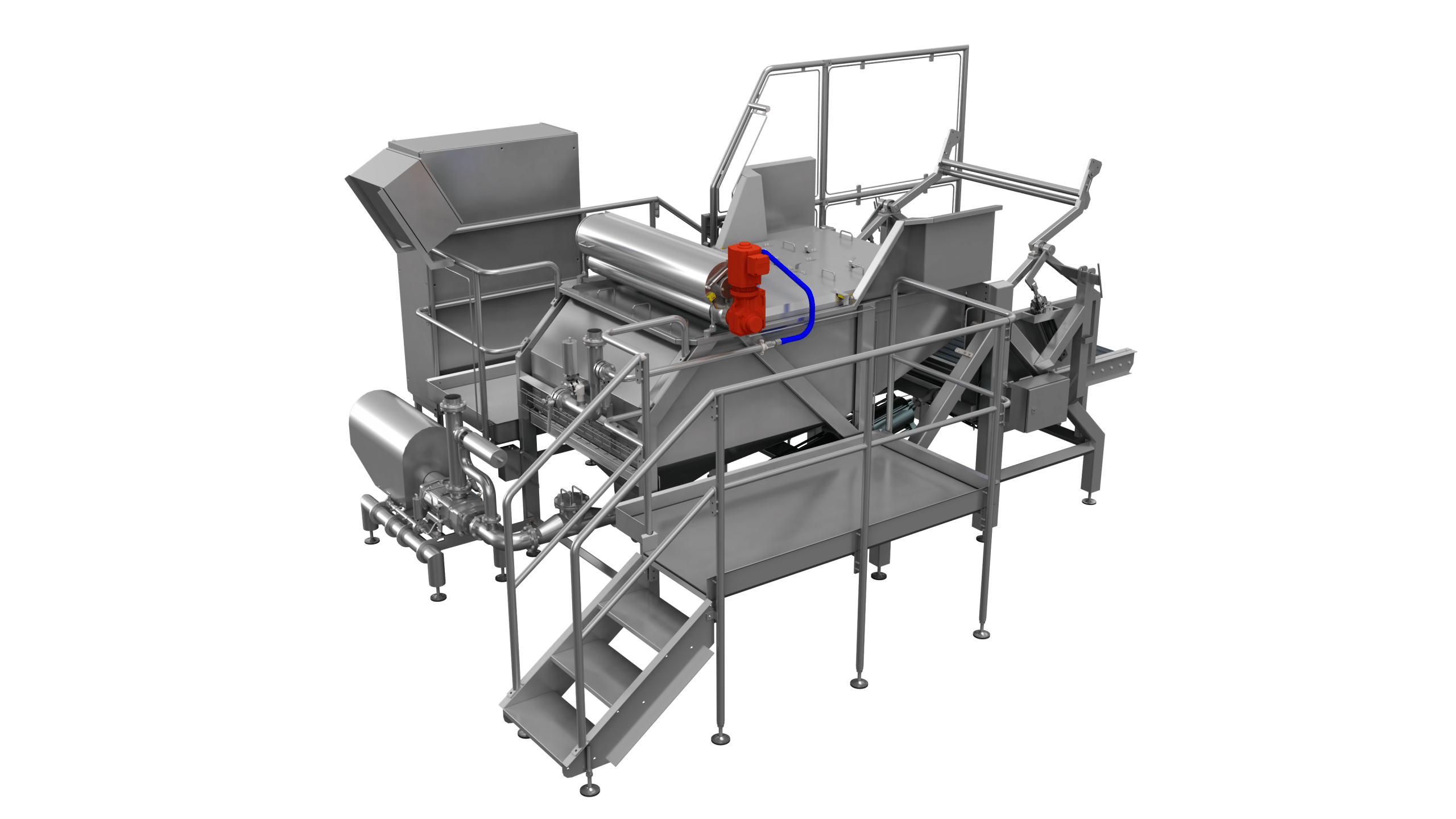

How FLUIVAC works:

FLUIVAC cleans your systems in 4 steps, with sterile filter air and a minimum amount of water:

1. PUSH

FLUIVAC pushes the product out of the pipes in a controlled manner, with compressed air. This saves 60-70% of your product.

2. BLOW

FLUIVAC blows the rest of the product out of the pipes with an internal compressor, which saves 90 to 98% of your product.

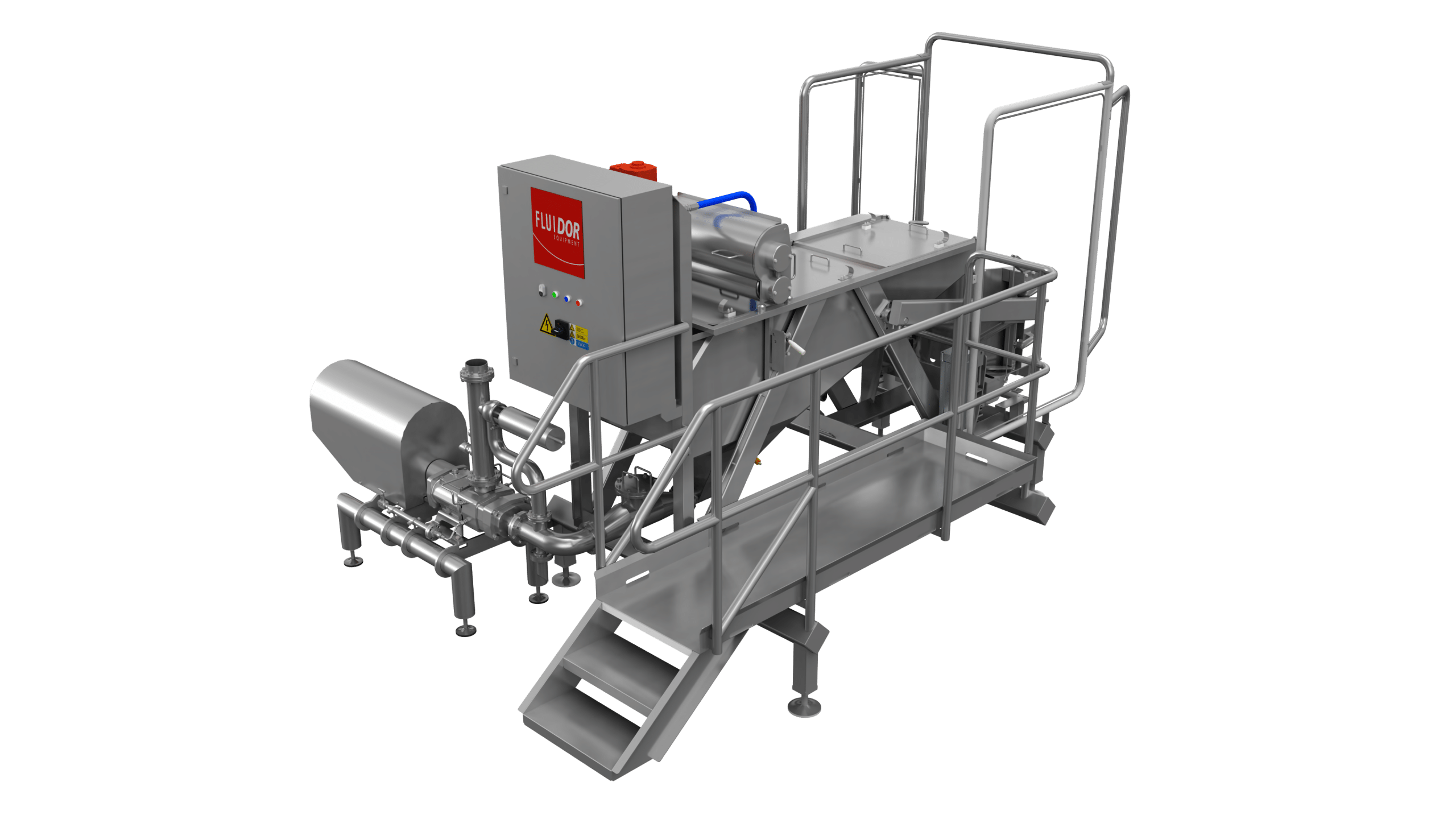

3. RINSE

FLUIVAC uses a small amount of water to flush out the last product from the inner surface, for a visually clean pipe.

4. DRY

FLUIVAC dries the pipes, ready for new production. The next production doesn’t mix with water or other product, so there’s no waste from the start.

When you combine FLUIVAC with your CIP system, you will also save extra water and detergent.

FLUIVAC helps you achieve your sustainability goals. With FLUIVAC, you recover up to 98% of valuable produce and save up to 96% of water plus a lot of energy and time.

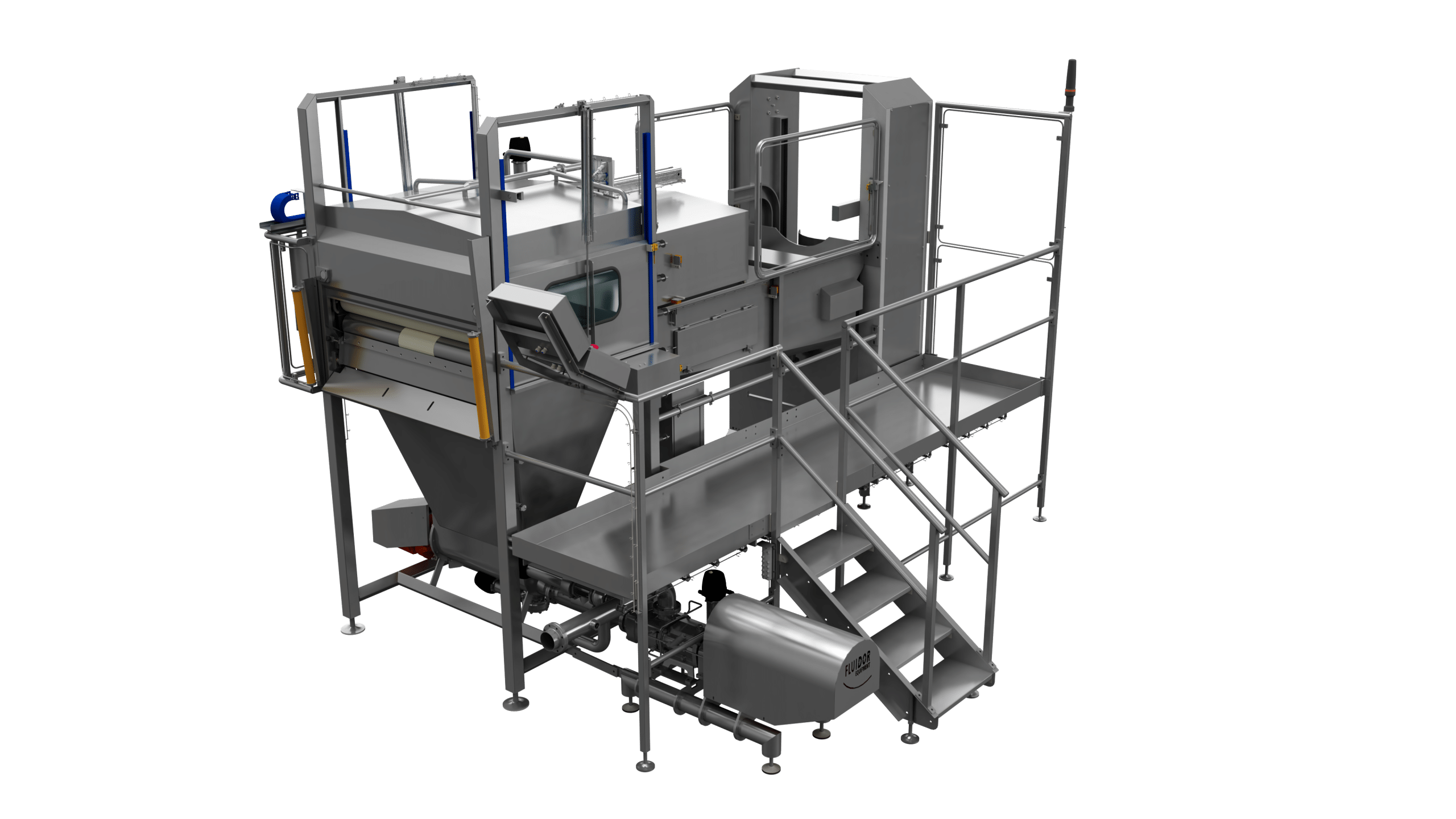

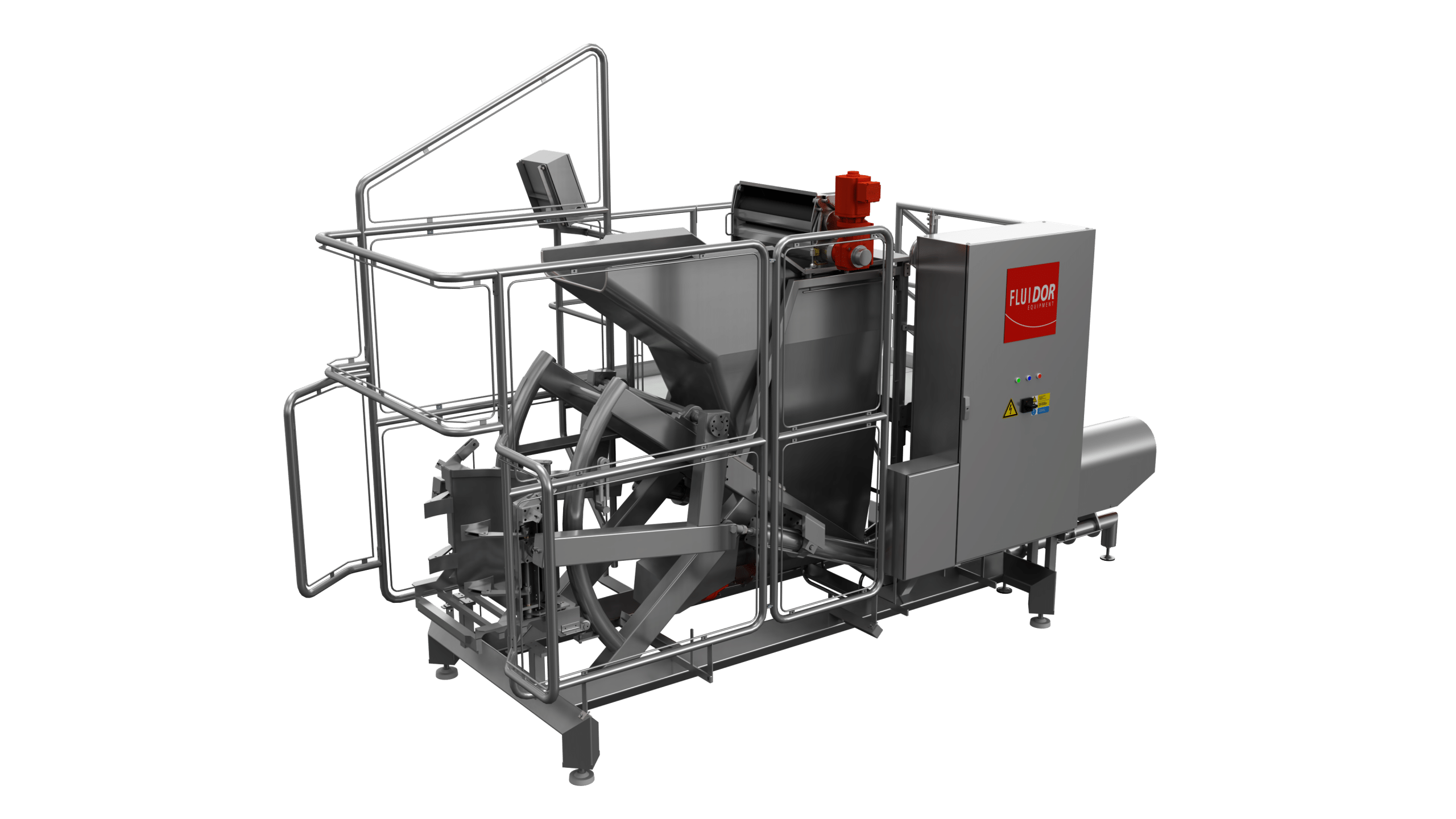

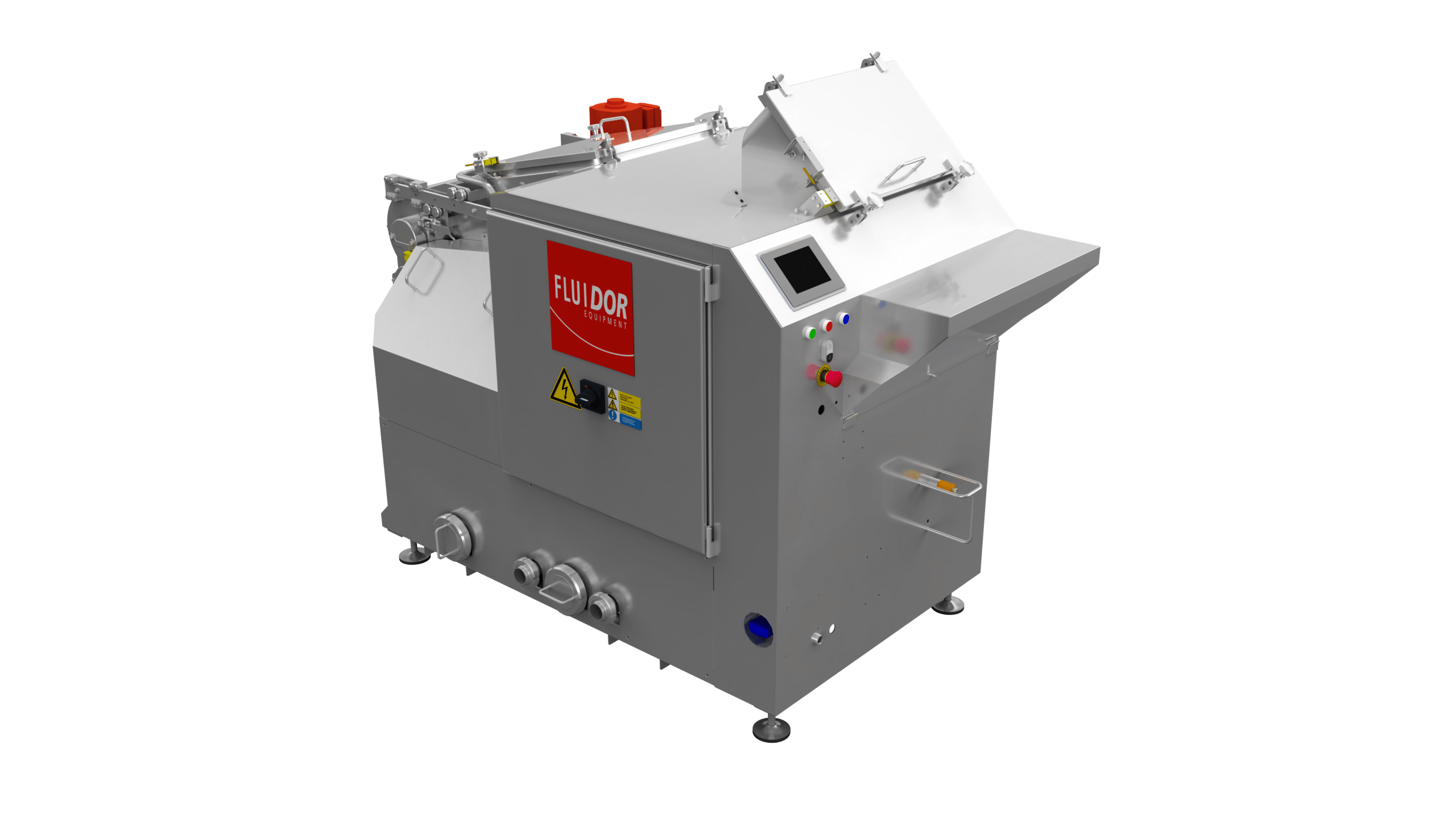

This compact built unit with integrated Siemens or Allen Bradley HMI control panel, consists of a complete configuration of high quality components like compressor, pressure vessels, (control-)valves and sensors.

FLUIVAC is user-friendly by simple parameter settings for easy process operation. Once set up, it can be integrated in an automatic production process, using PROFINET or Ethernet/IP.