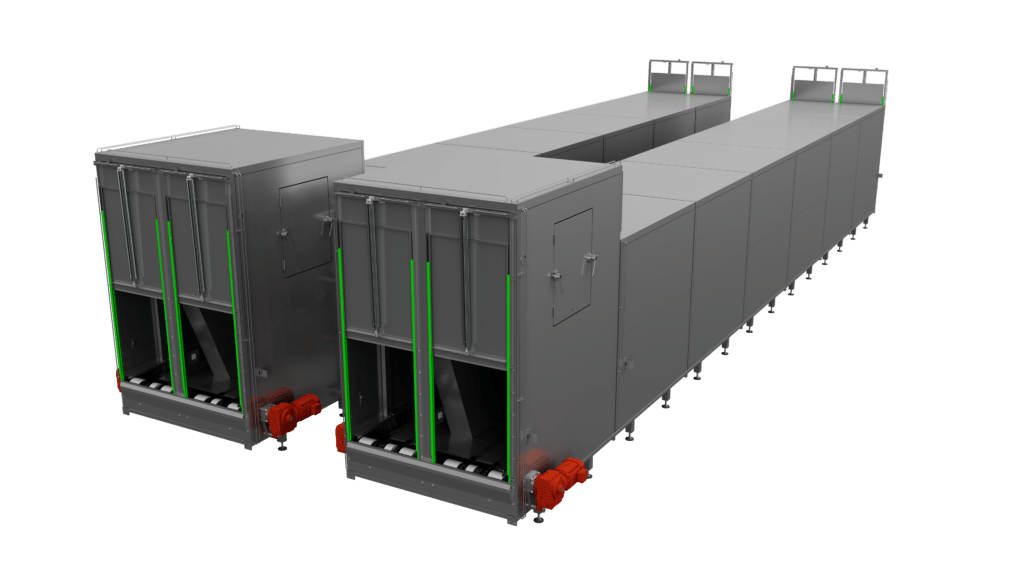

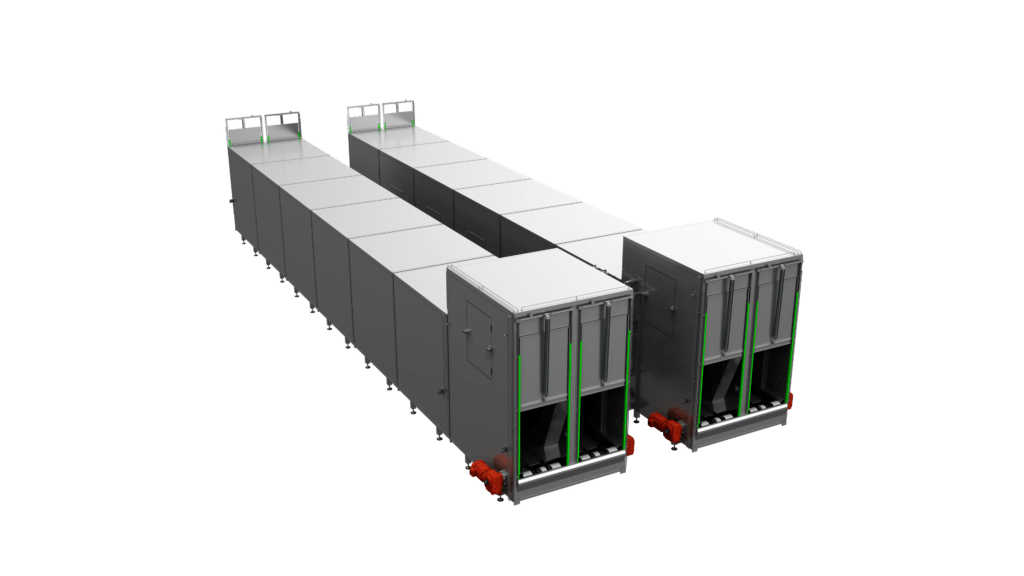

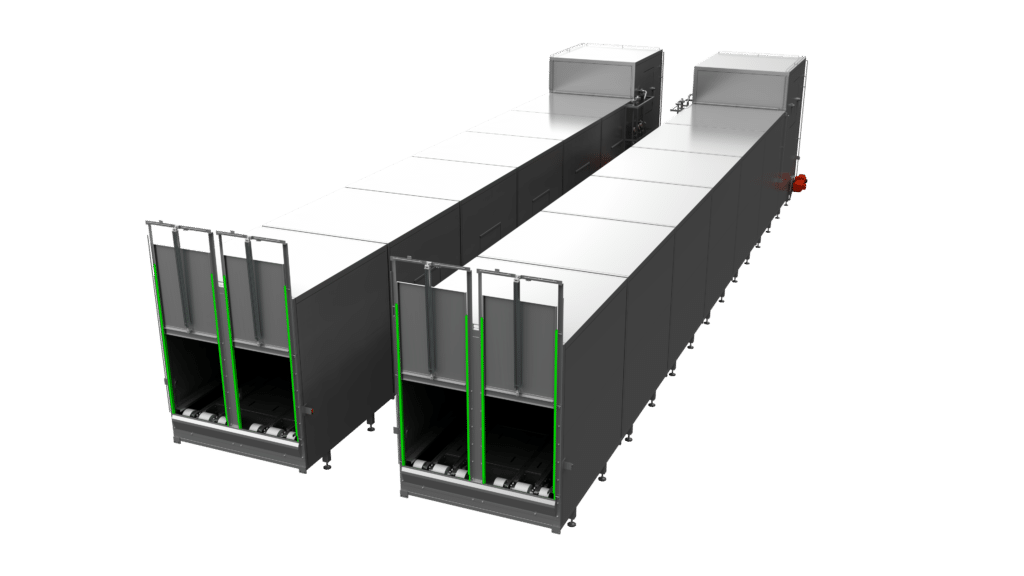

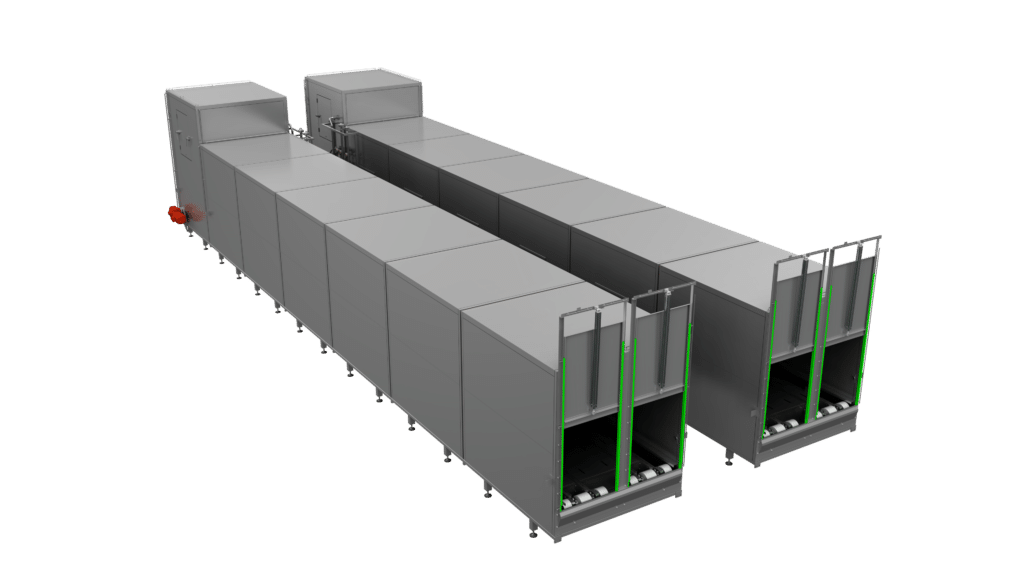

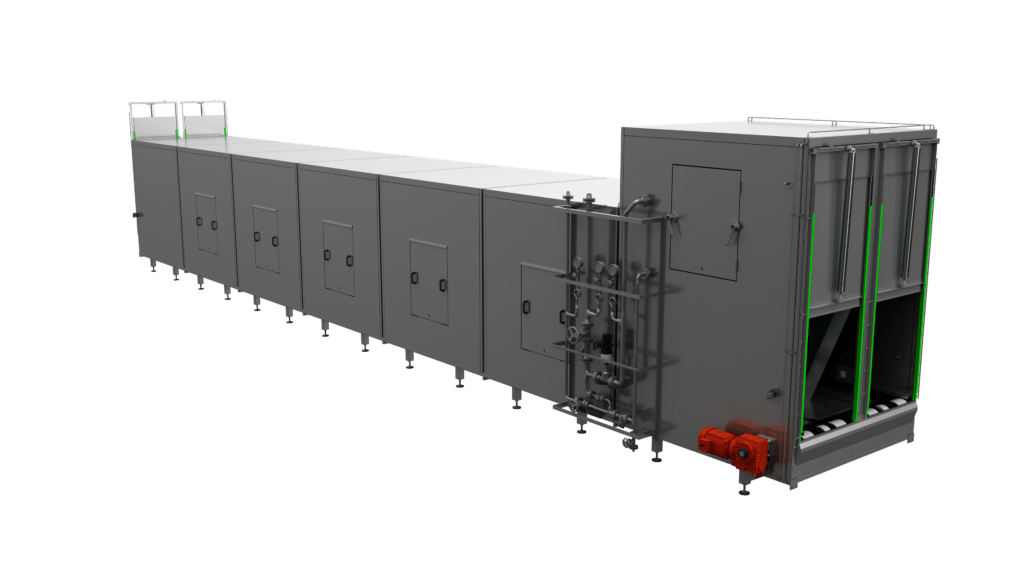

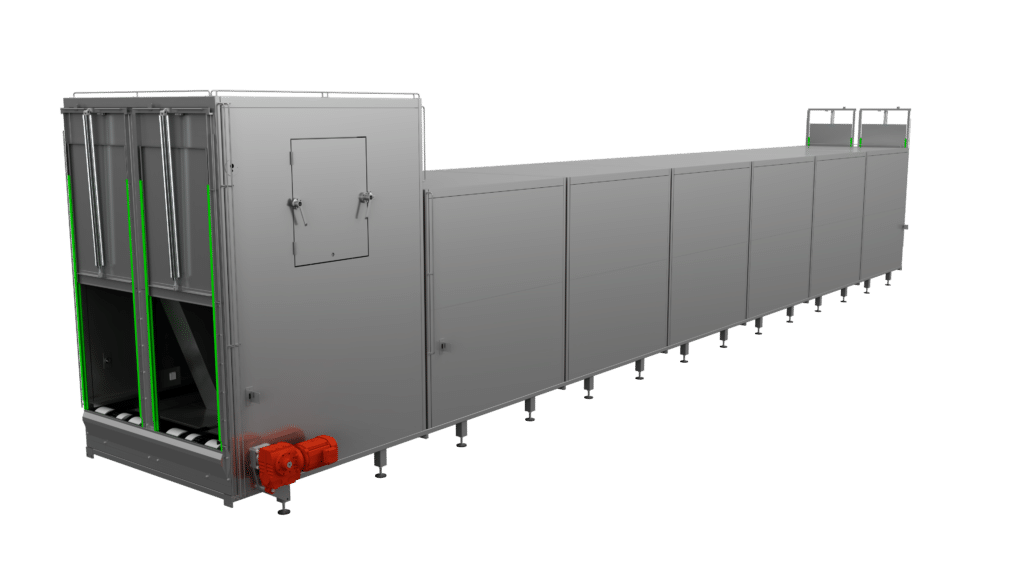

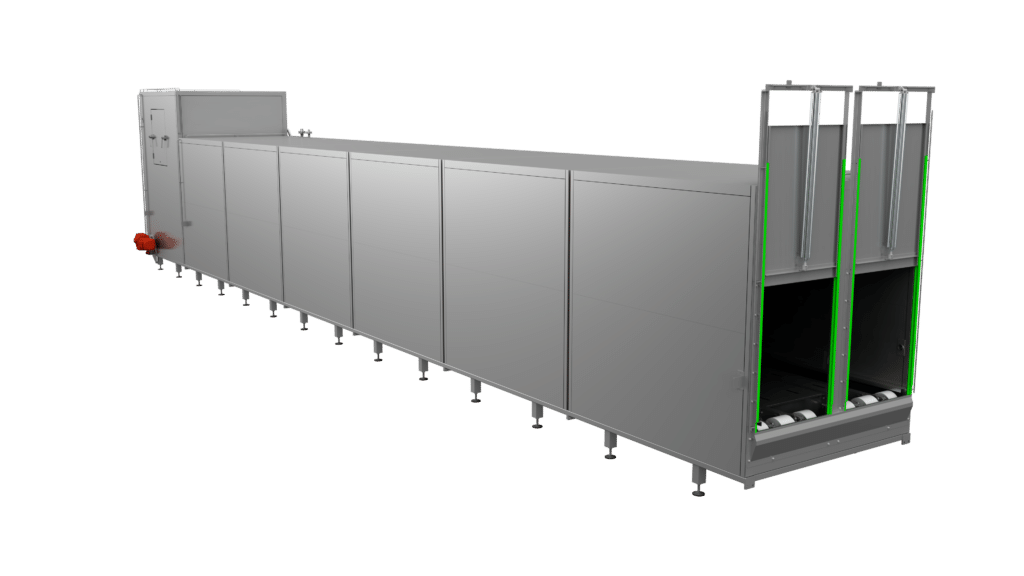

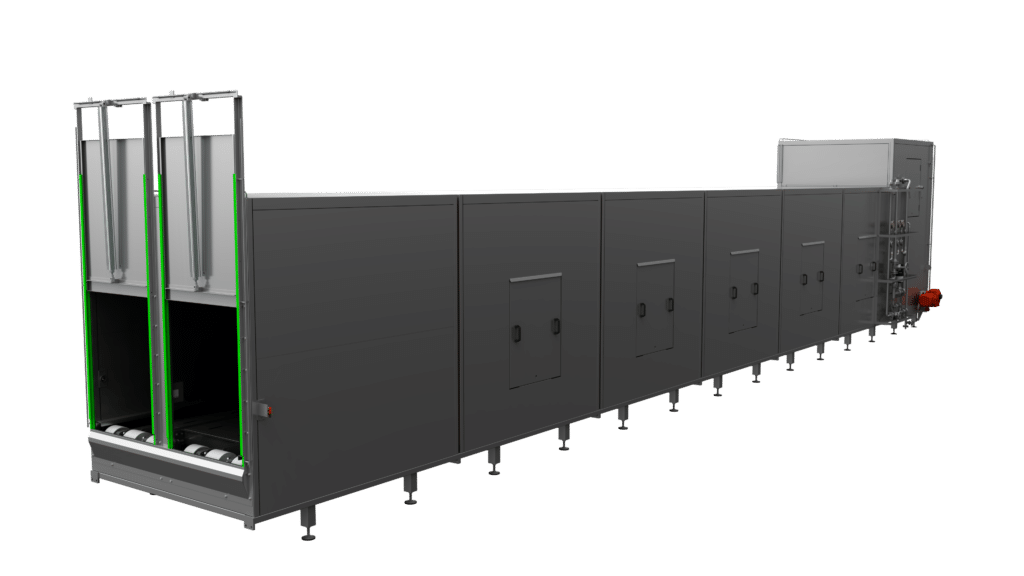

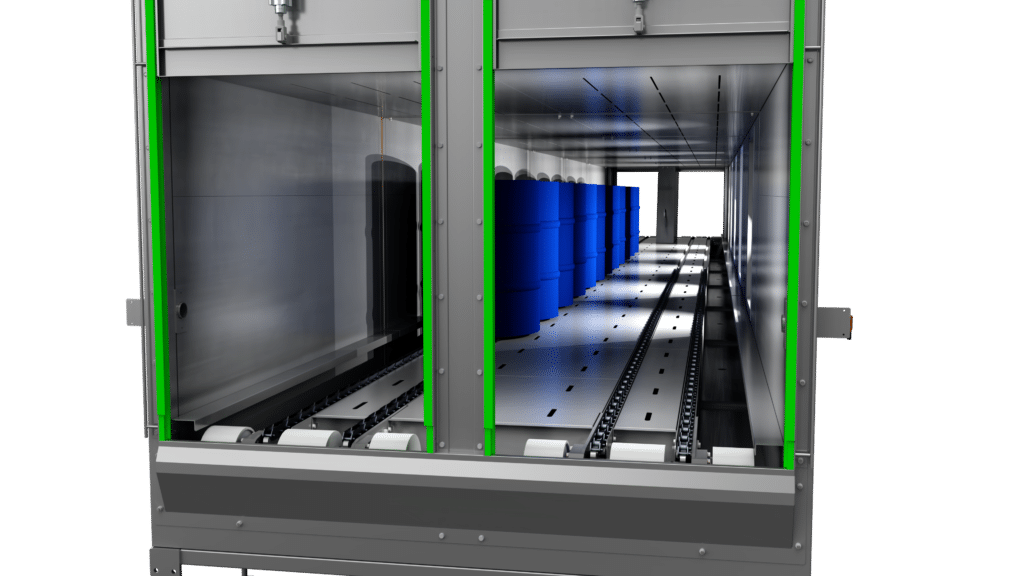

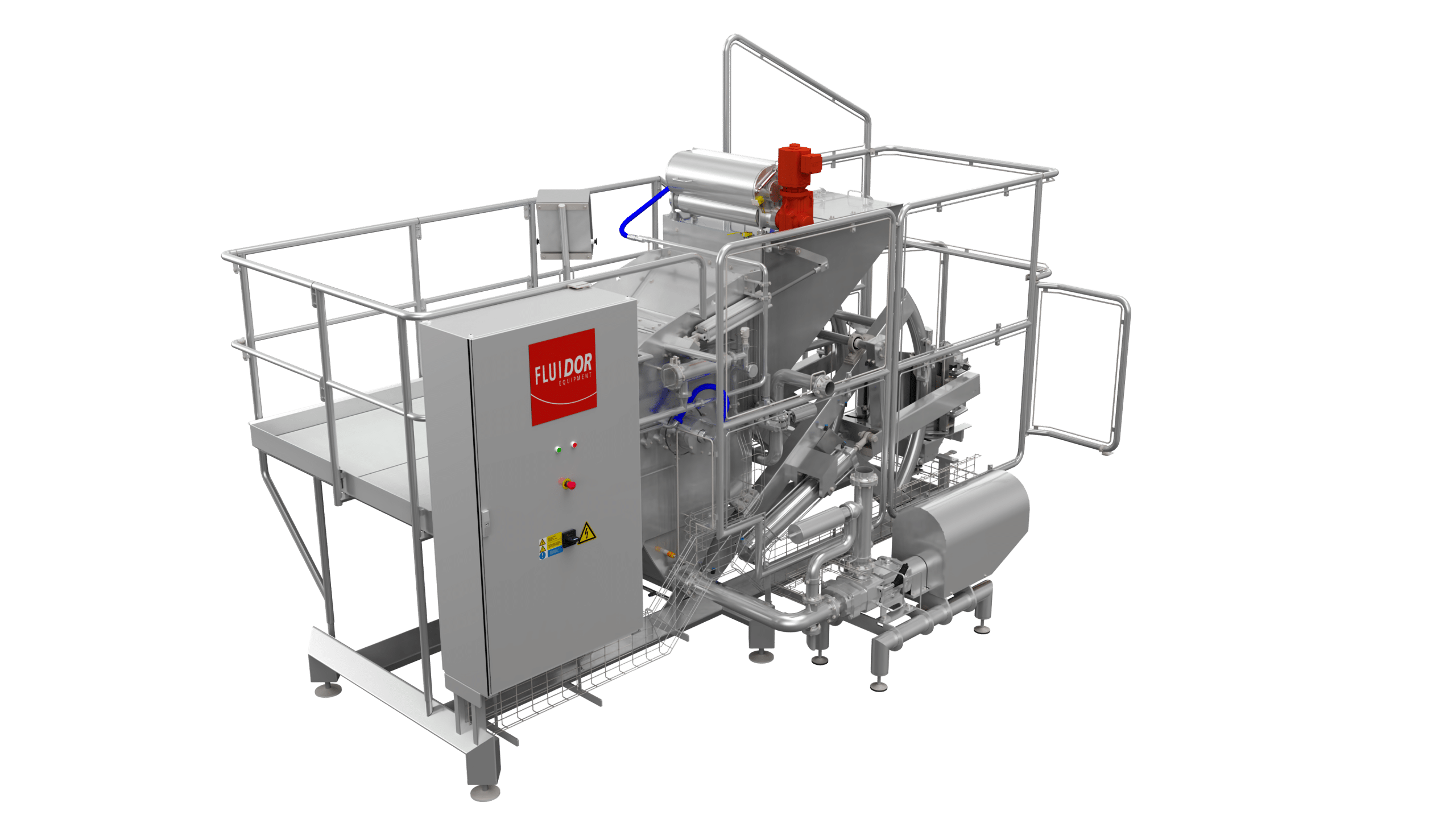

Thawing tunnel

With the Thawing tunnel, you can pre-thaw deep-frozen products and facilitate the release from the drum during dumping into the Drum Dumper Ice Crusher (DPRICS).

Pre-thaw deep-frozen products for easy tipping of drums

Does your industry require efficient and controlled pre-thawing of deep-frozen products in order to enhance processing efficiency?

The Fluidor Thawing Tunnel is designed to pre-thaw the outer shell of ice blocks, allowing for easy tipping of 200 litre drums containing deep-frozen fruit juices, fruit pulps and fruit purees.

This thawing process facilitates the release of products from the drum during dumping into the Drum Dumper Ice Crusher (DPRICS). The tunnel improves efficiency and operational flexibility, while preserving your product quality.

Depending on drum infeed & product, the maximum capacity based on batches is 20 drums per hour. For a corresponding maximum capacity to the DPRICS and CIM, two Thawing Tunnels of 32 drums each are advised.

How the Thawing tunnel works:

- Frequency driven shuttles transport the drums in pairs in and out of the Thawing Tunnel.

- Two driven chain tracks take care of the transport inside the Tunnel.

- On top of the Tunnel, hot air is created by circulating air through a steam / air heat exchanger.

- A frequency driven fan circulates the hot air through an air duct from which the air is precisely guided along the drums.

- Only the outer shell and top surface of around 2-3 cm is thawed, the rest of the product remains deep frozen to maintain product quality.

The capacity of the Thawing Tunnel is adjustable by duration time per track or drum and temperature (per tunnel). These parameters make it possible to pre-thaw smaller batches of different products with different pre-thawing times. The modular built configuration offers a flexible pre-thawing process.

The Thawing tunnel efficiently pre-thaws only the outer shell of the ice block, facilitates easy tipping and processing of deep-frozen products and speeds up production.

The Thawing tunnel maintains the core of the product deep-frozen, to ensure the quality of the product is preserved.

The Thawing tunnel offers adjustable parameters for different pre-thawing times and modular configuration, which makes it suitable for various product types and batch sizes.