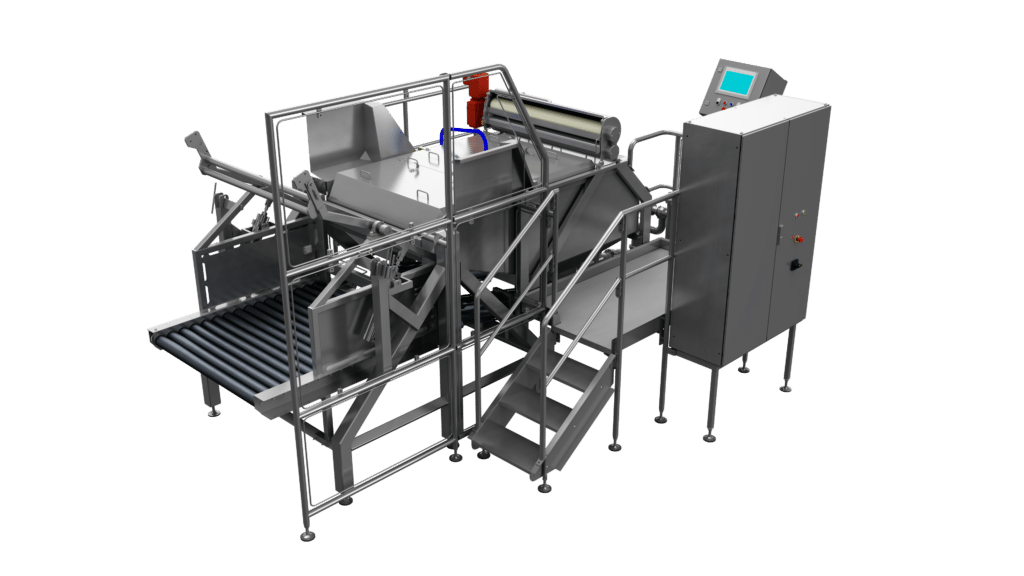

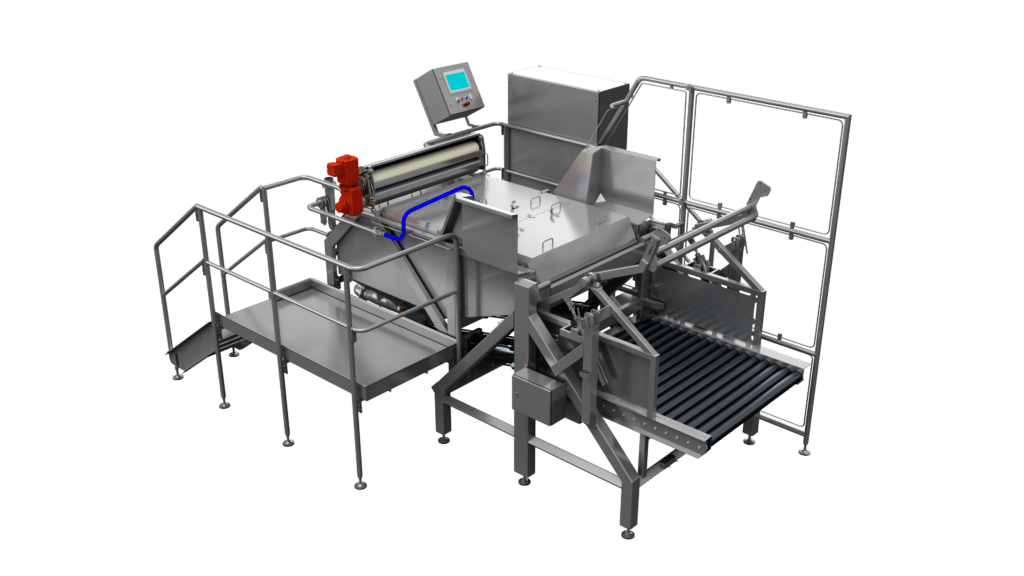

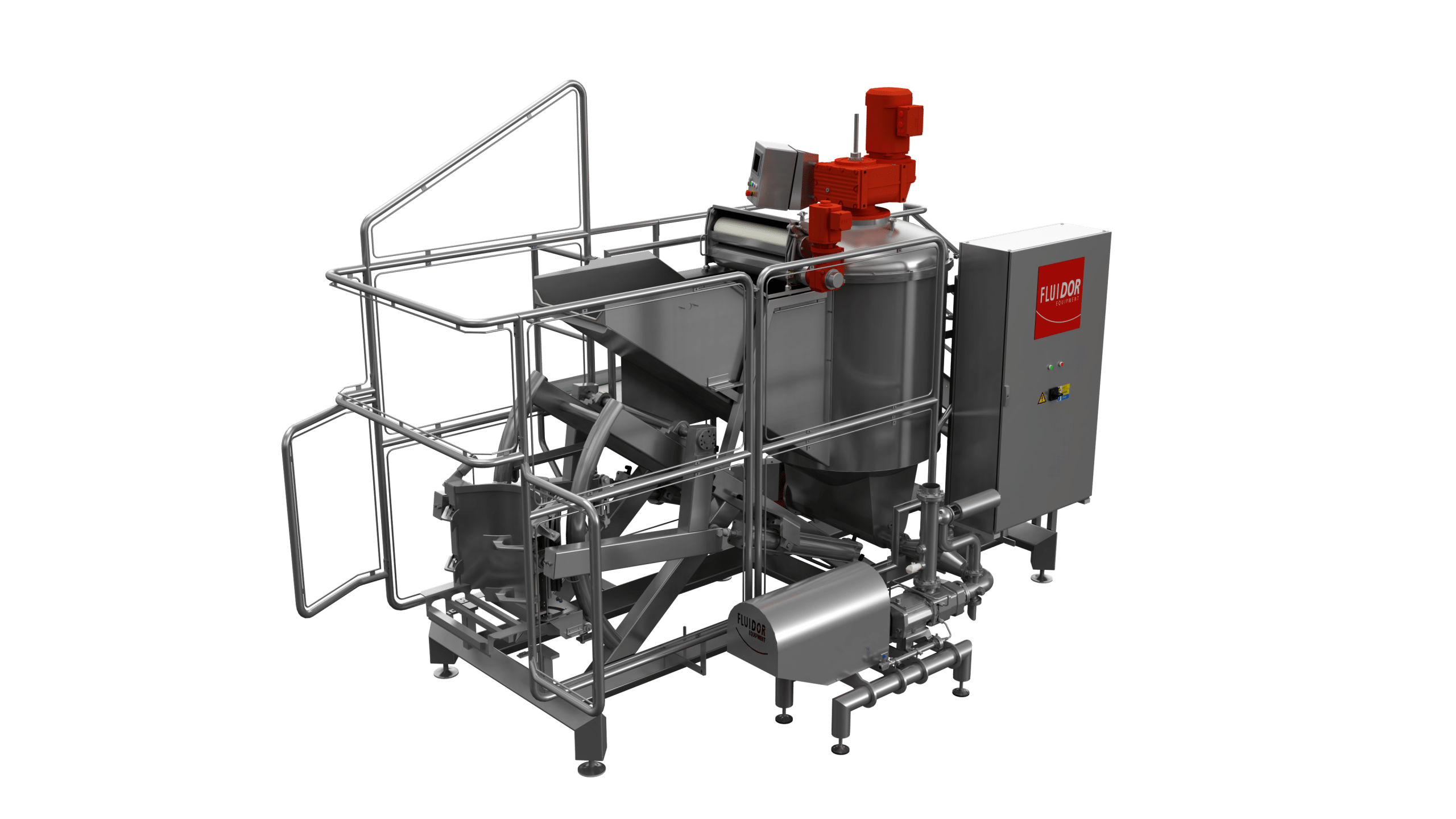

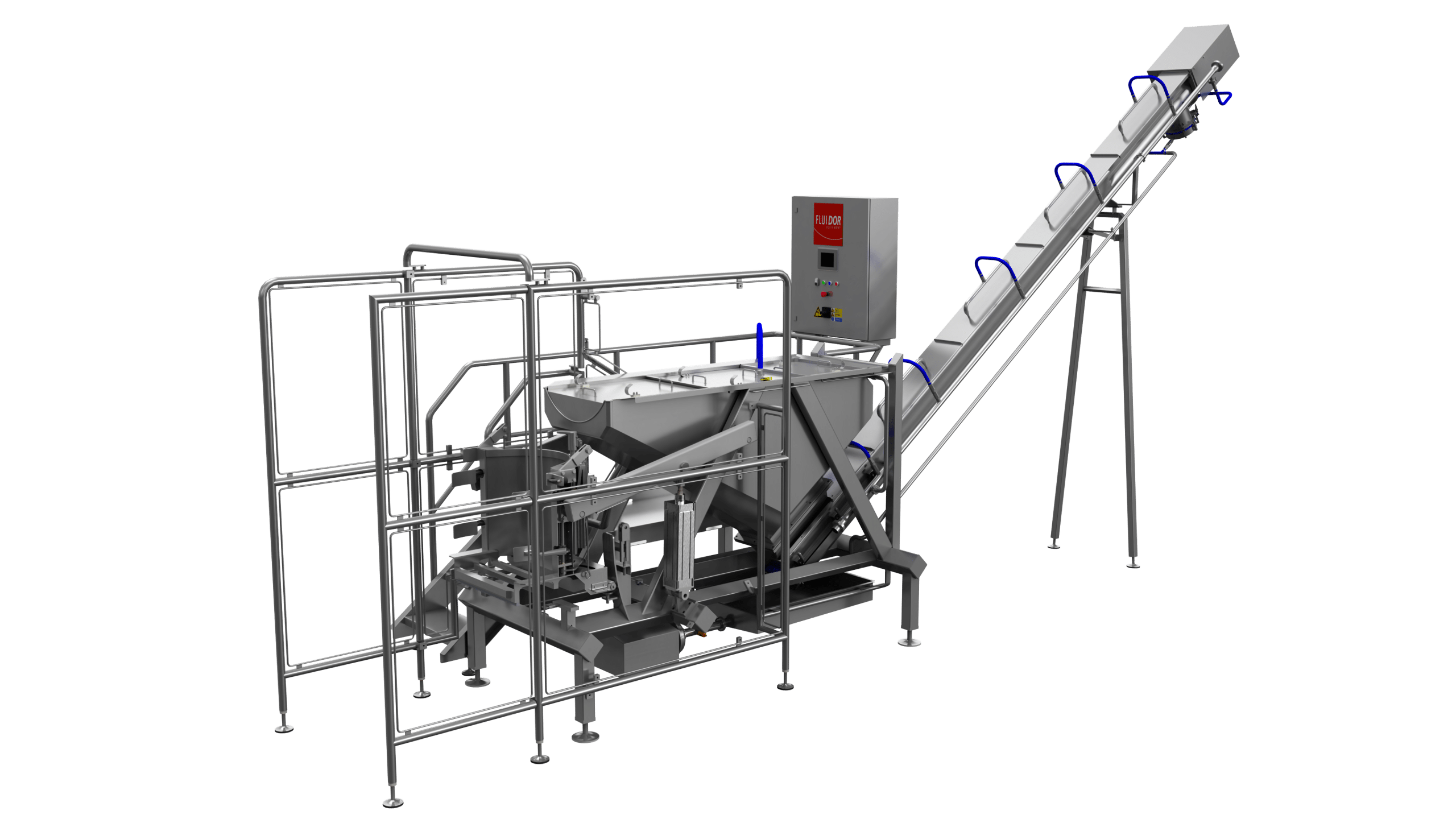

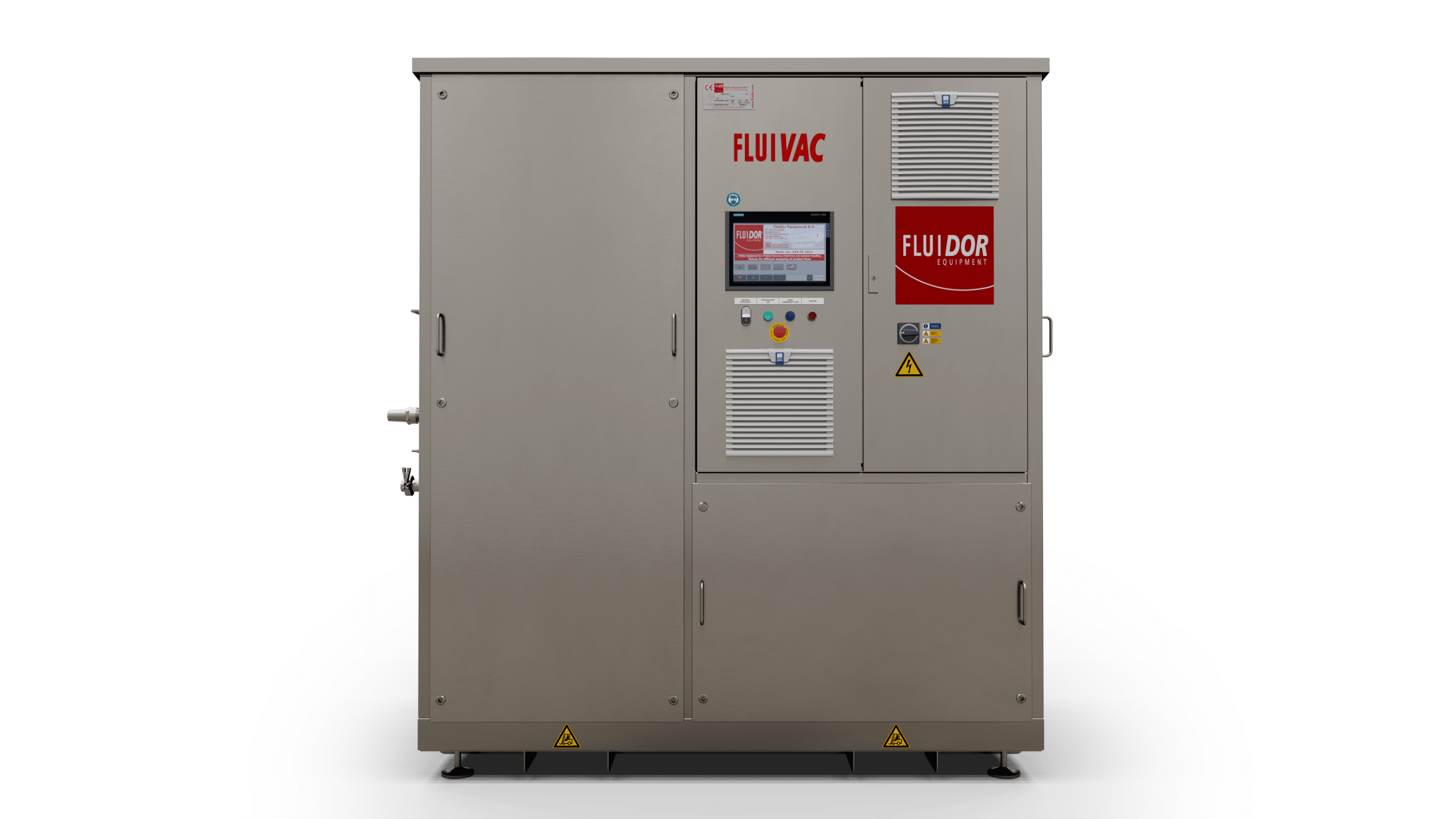

Tote Bin Dumper-Fluids (TBD-Fluids)

With the Tote Bin Dumper-Fluids (TBD-Fluids), you can safely and efficiently empty liquids from large storage containers. Save costs, waste less and ensure a consistent production process.

Empty tote bins and drums efficiently

Does your industry work with liquids stored in containers and do you want to transfer these liquids to production processes or other storage facilities? The Tote Bin Dumper-Fluids from Fluidor Equipment empties your tote bins and drums quickly, efficiently and safely.

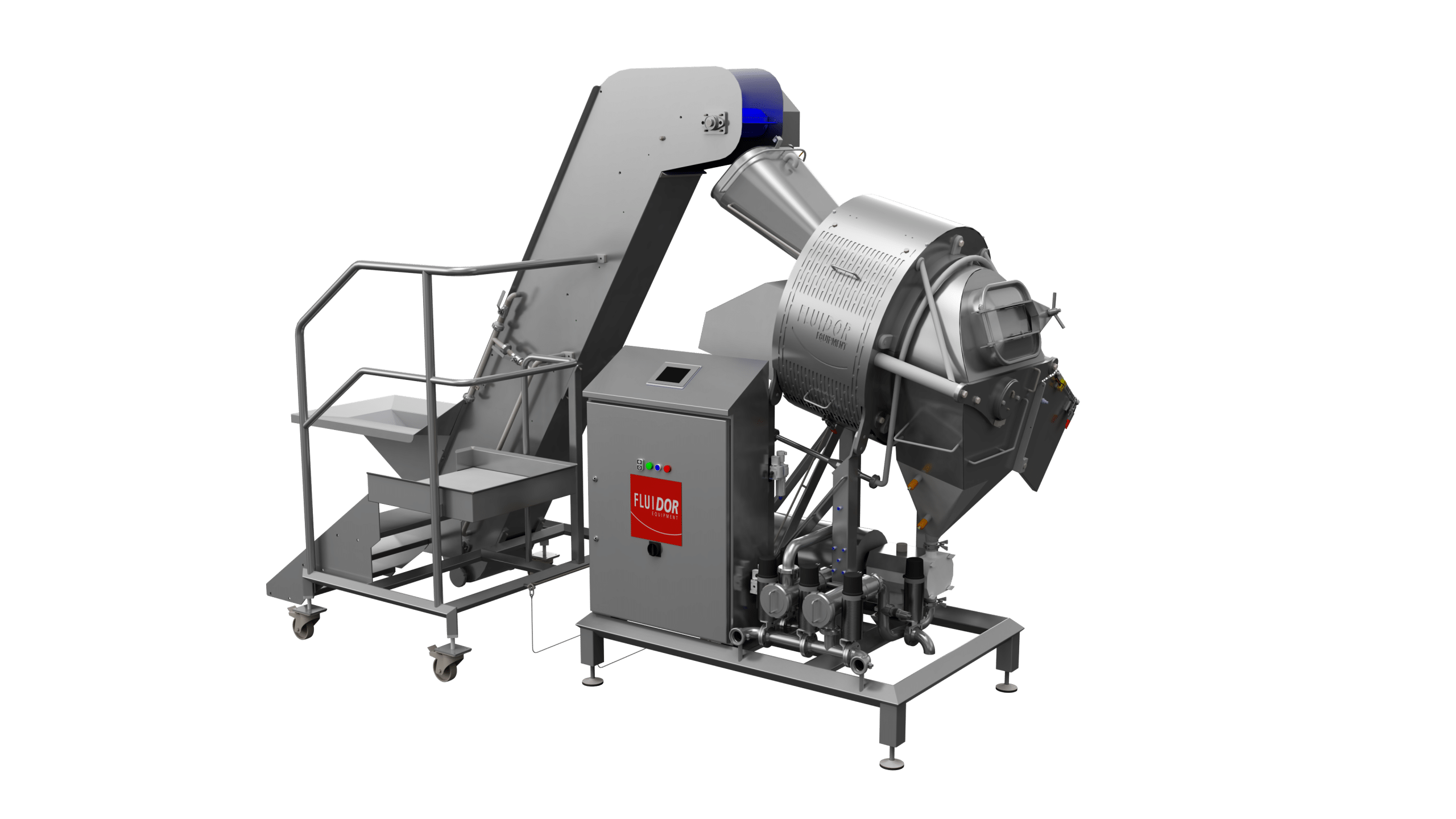

The TBD-Fluids is designed for an efficient emptying of tote bins and drums with liquid product in aseptic bags, like fruit juices and concentrates or other liquids up to 70°. Depending on the bin / drum infeed and your product, it can handle 20 tote bins or 40 drums per hour (2 drums per cycle).

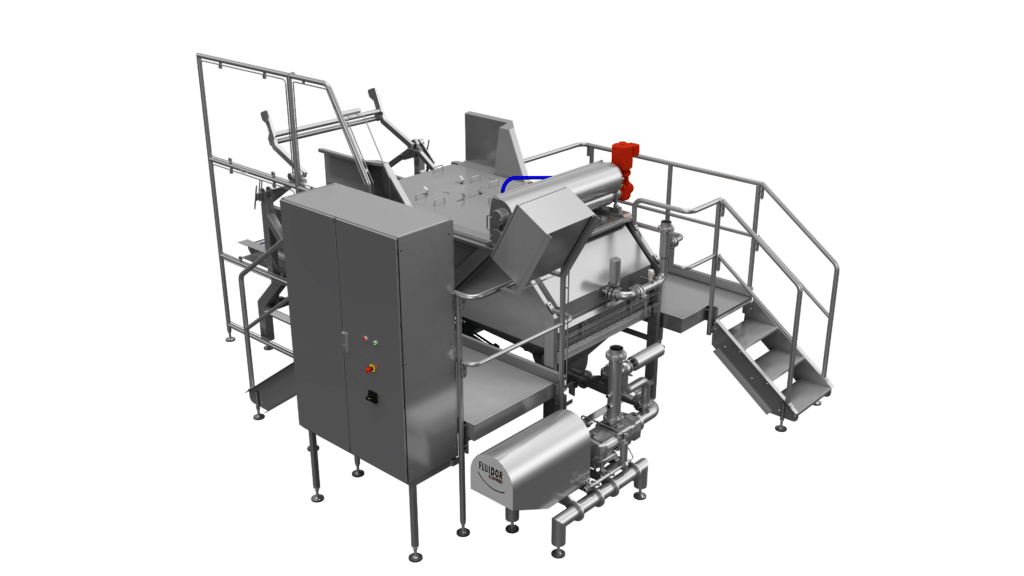

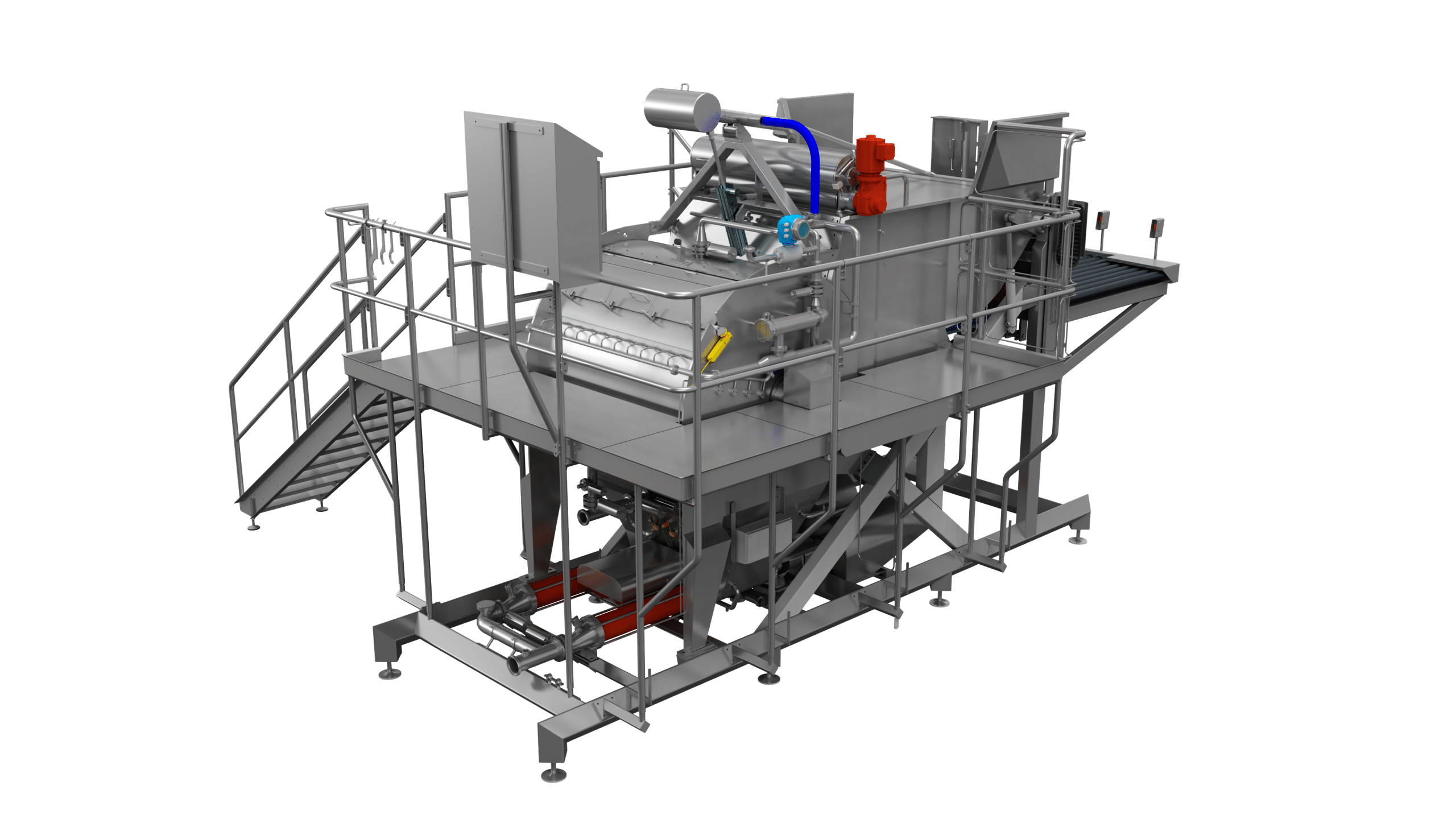

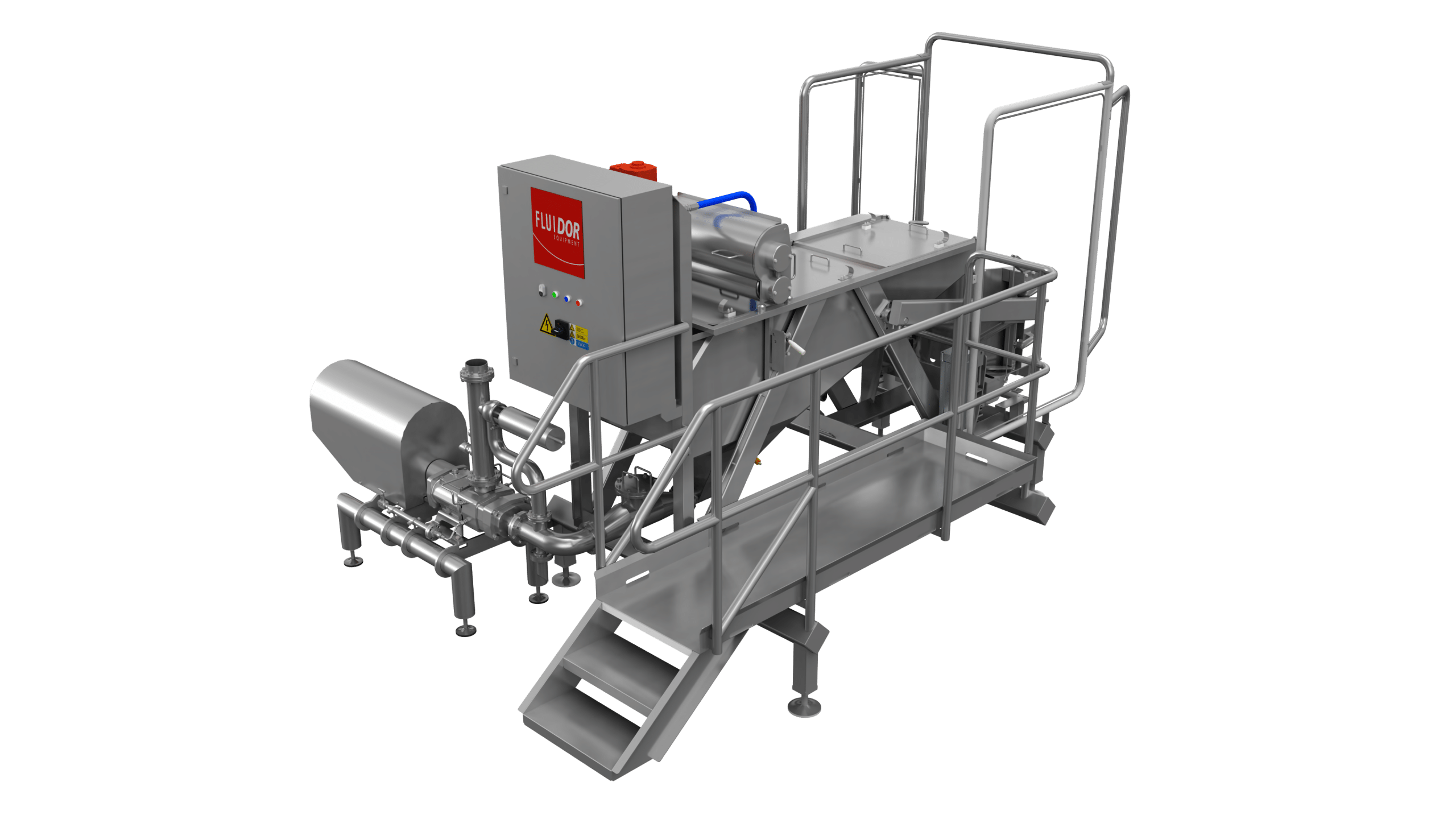

How the TBD-Fluids works:

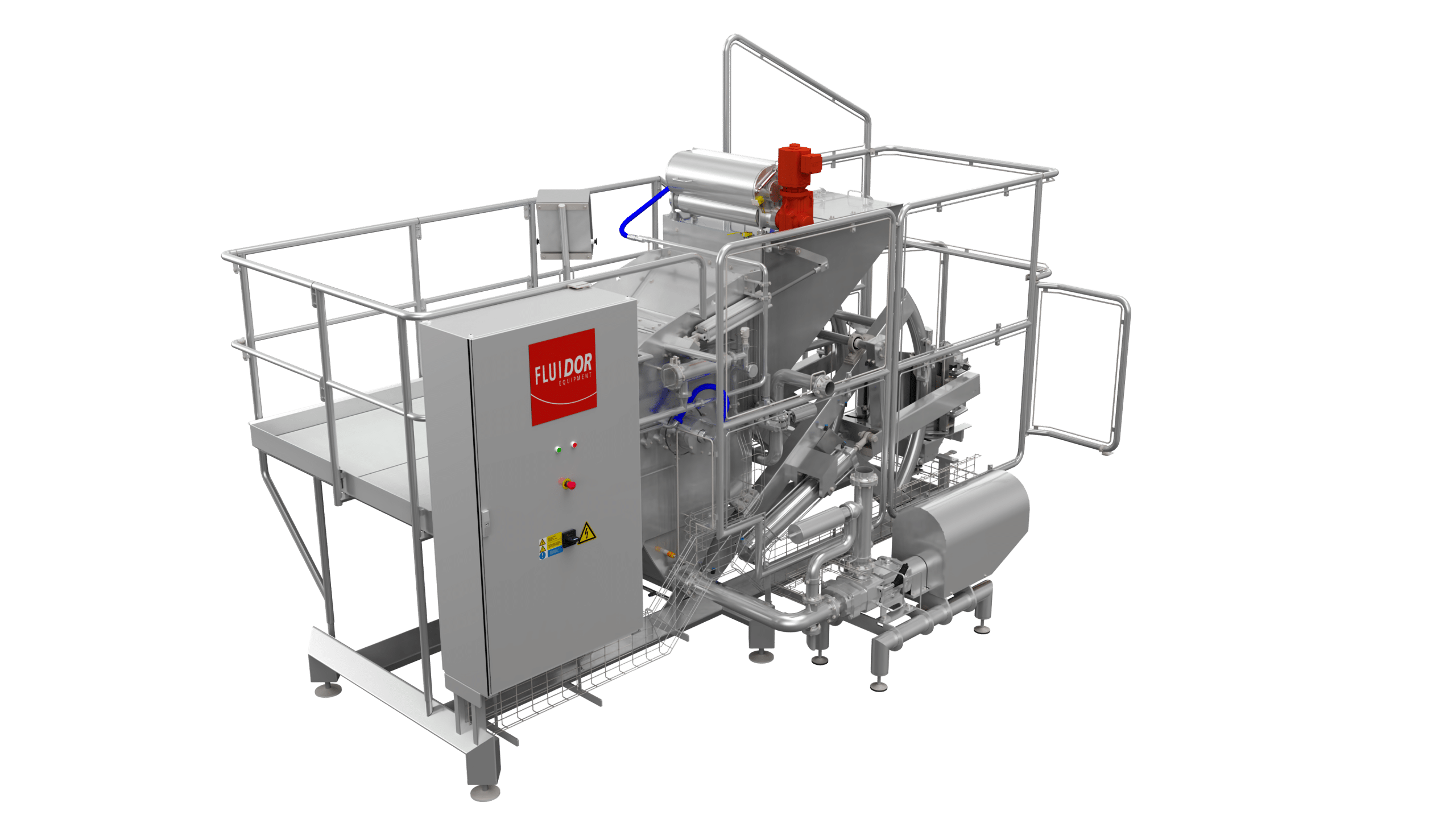

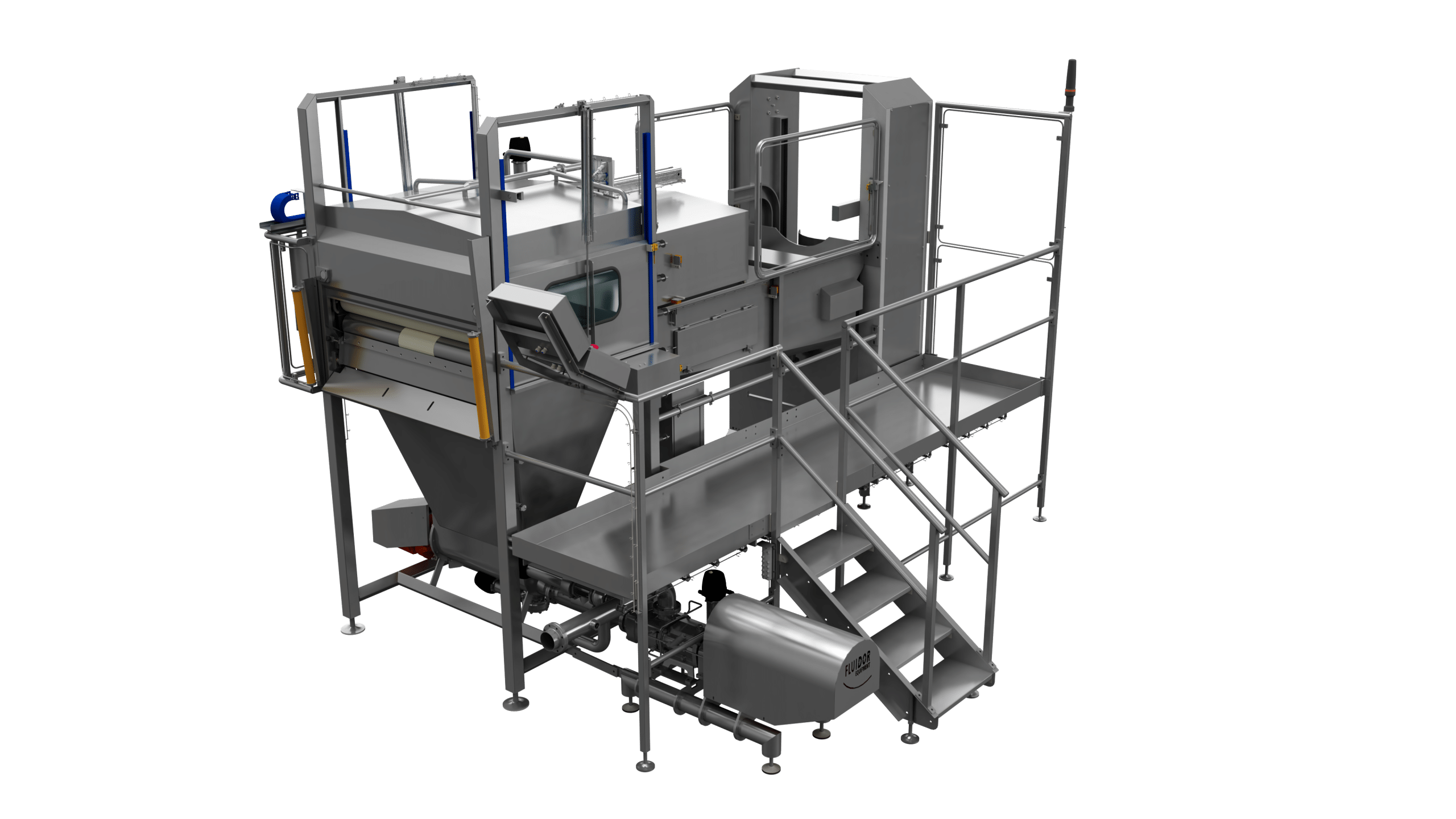

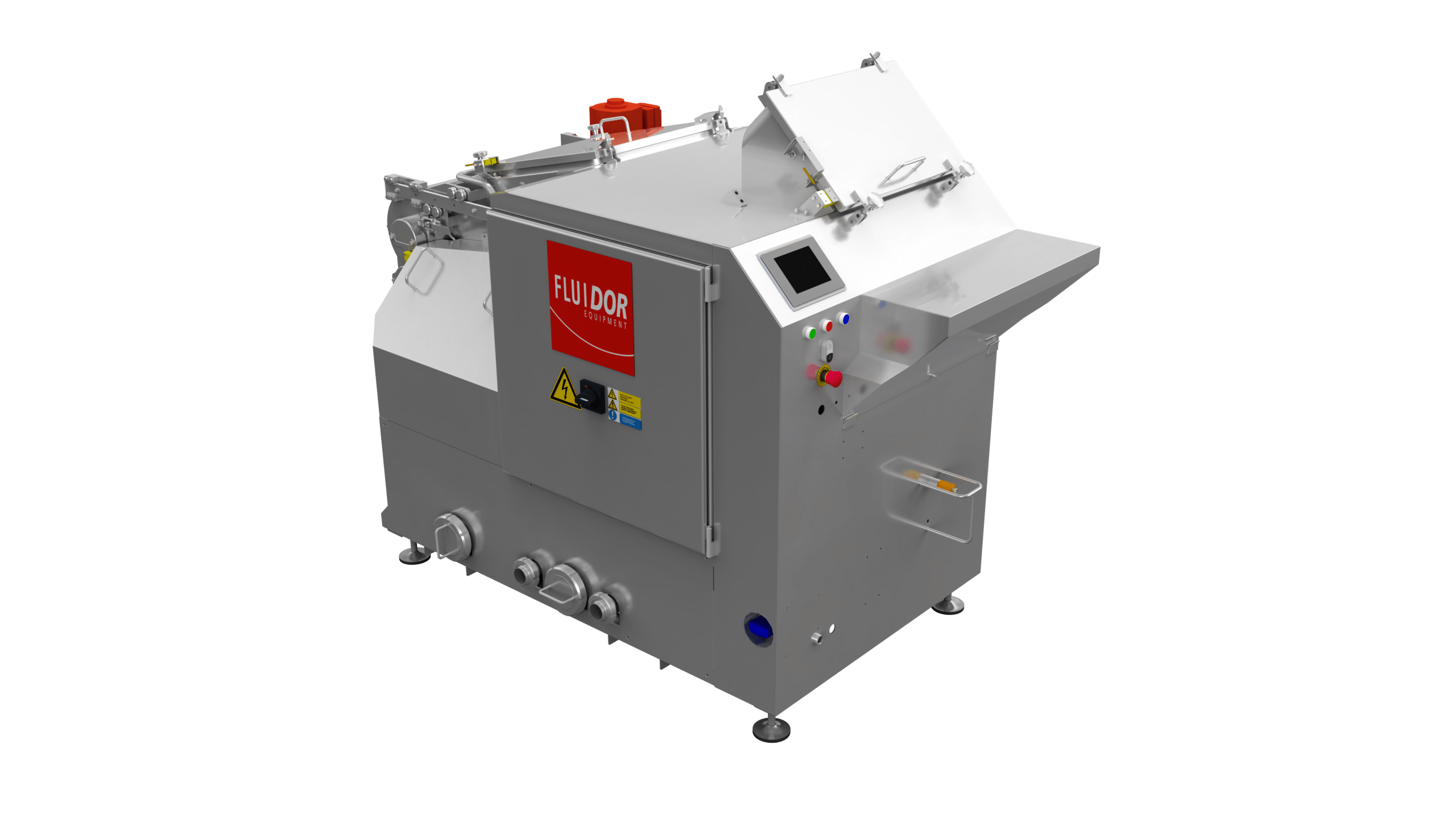

- After production, CIP covers are placed and TBD-Fluids can be integrated into your CIP-process.

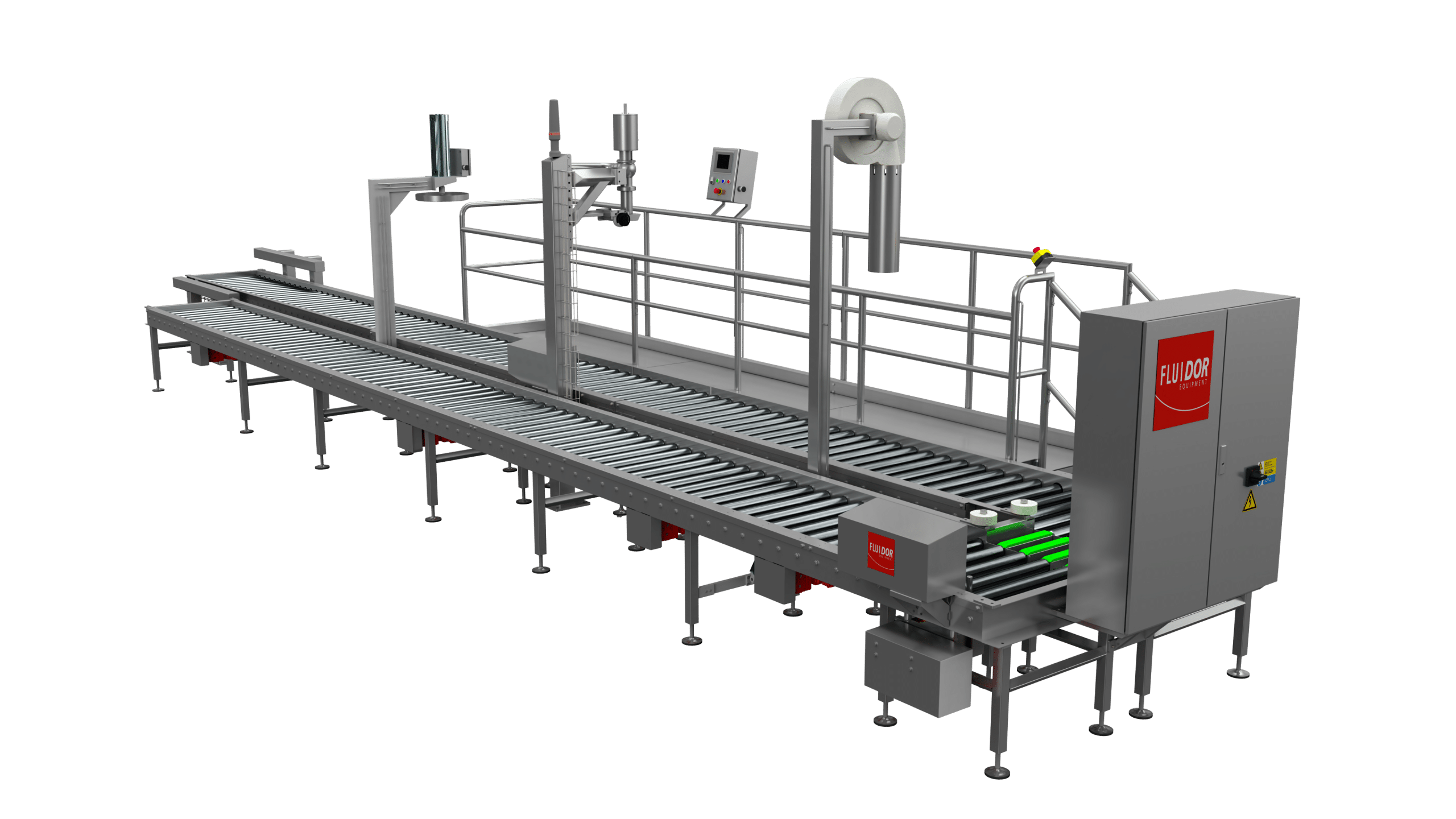

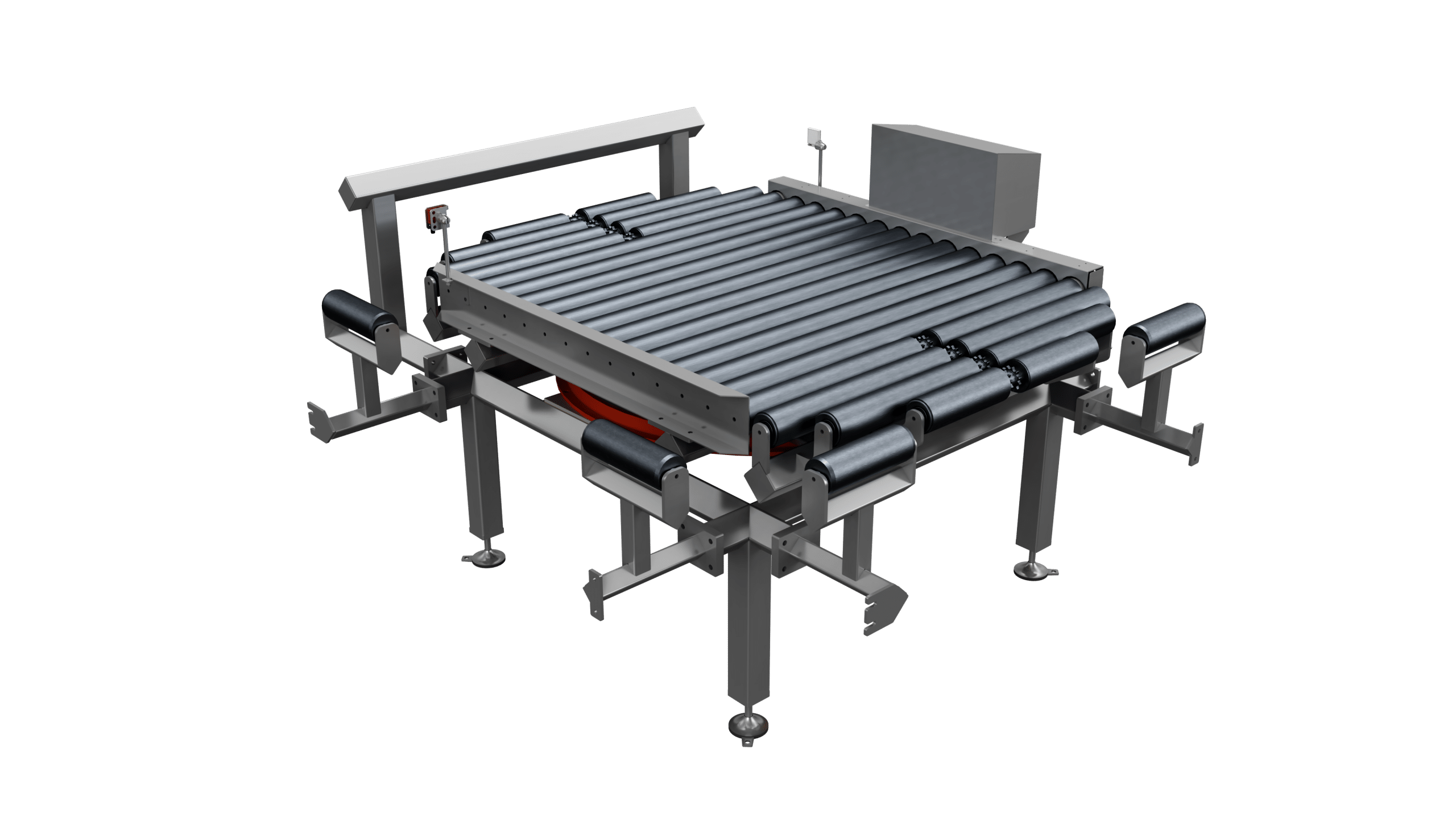

- The tote bins or drums are placed on the roller conveyor system by fork lift truck.

- The covers are removed and the bag is opened by an operator.

- Bins and drums are centred for correct infeed in the bin/drum holder for pneumatic lifting / dumping.

- The bag falls on the grid and the product flows towards the product discharge pump.

- Operator feeds the bag into the squeezer, reducing the product loss to a bare minimum.

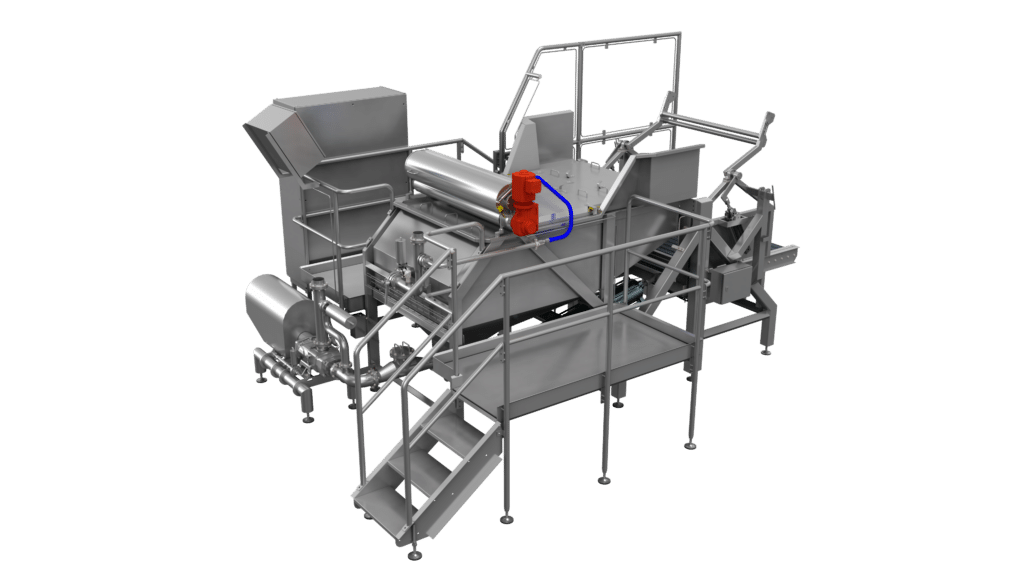

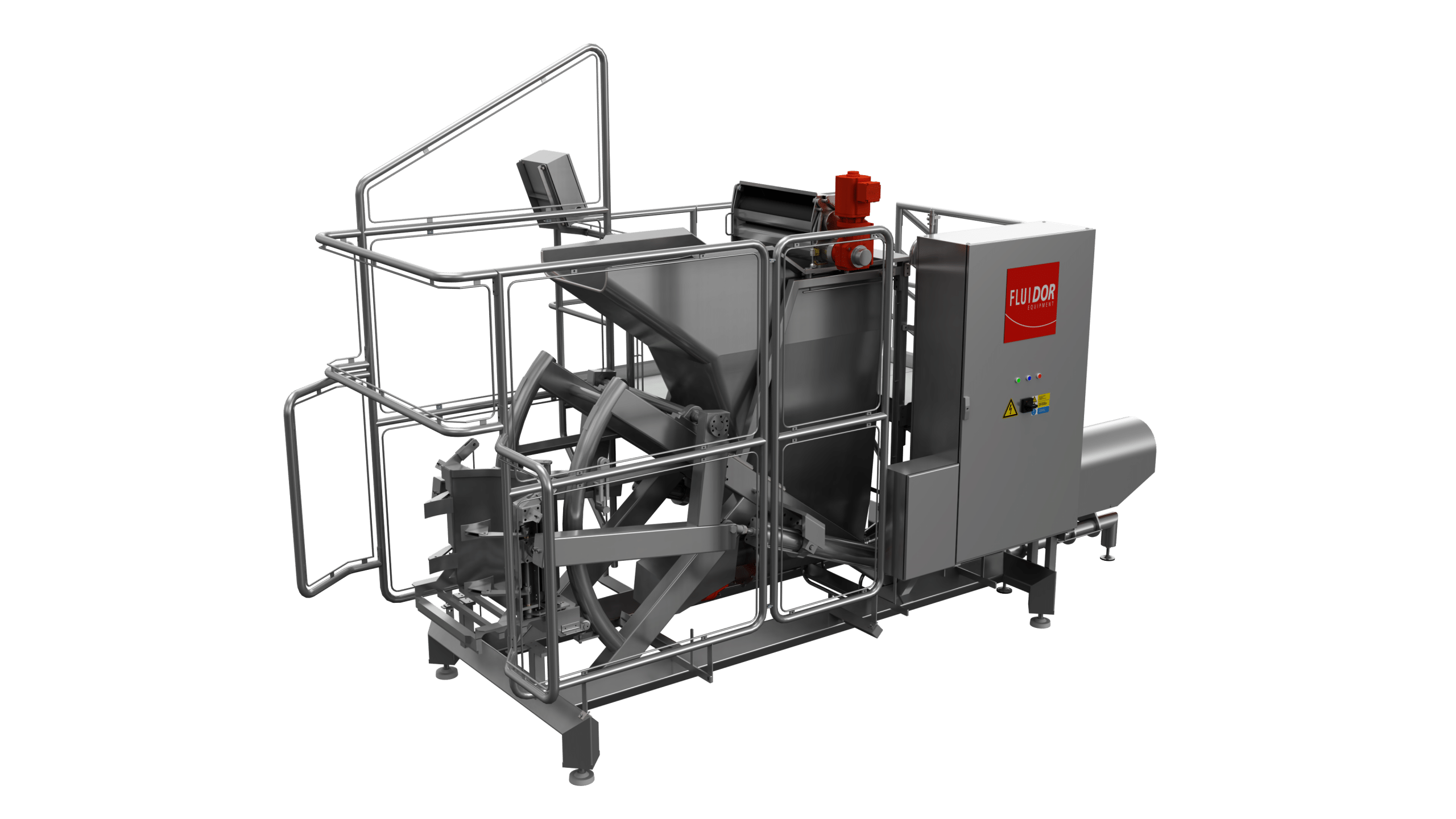

The TBD-Fluids empties tote bins and drums fast and consistent, which increases production throughput and saves time.

The TBD-Fluids minimises the risk of spills and accidents, reducing manual lifting and tilting. For a safer work environment and less physical strain on workers.

The TBD-Fluids automates and integrates into your production lines, designed to completely empty containers. That results in lower labour costs, less material waste and lower maintenance expenses.