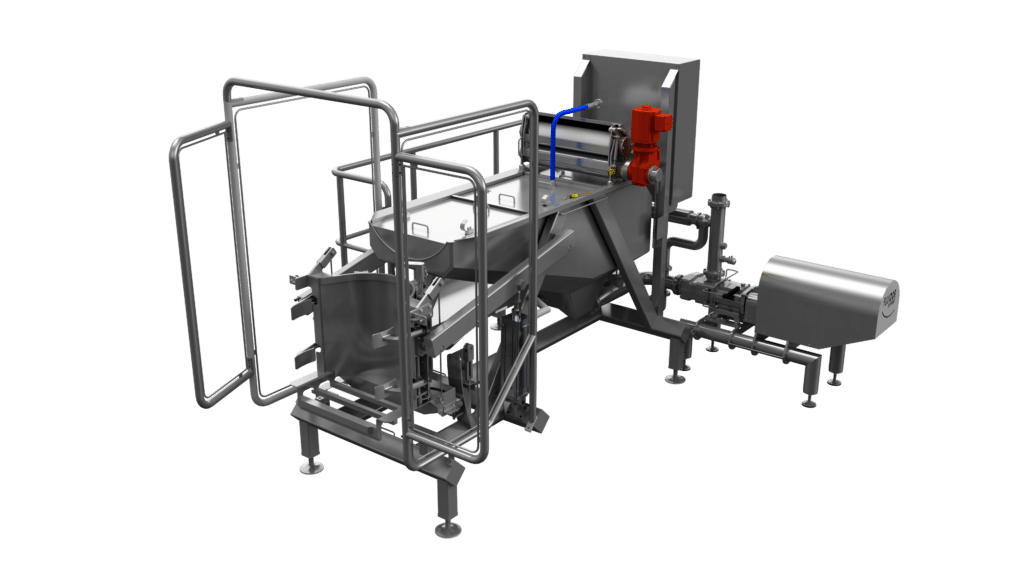

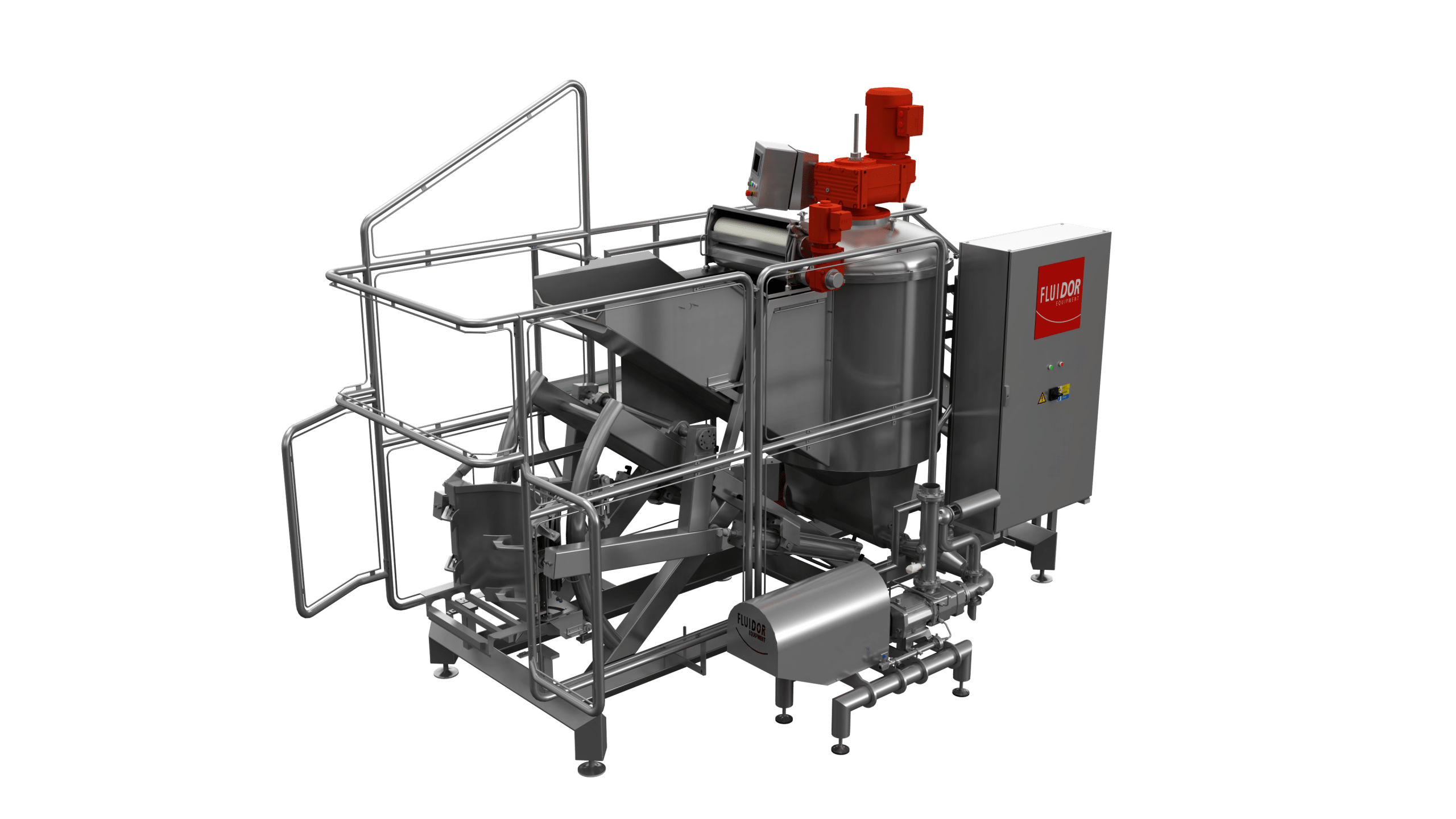

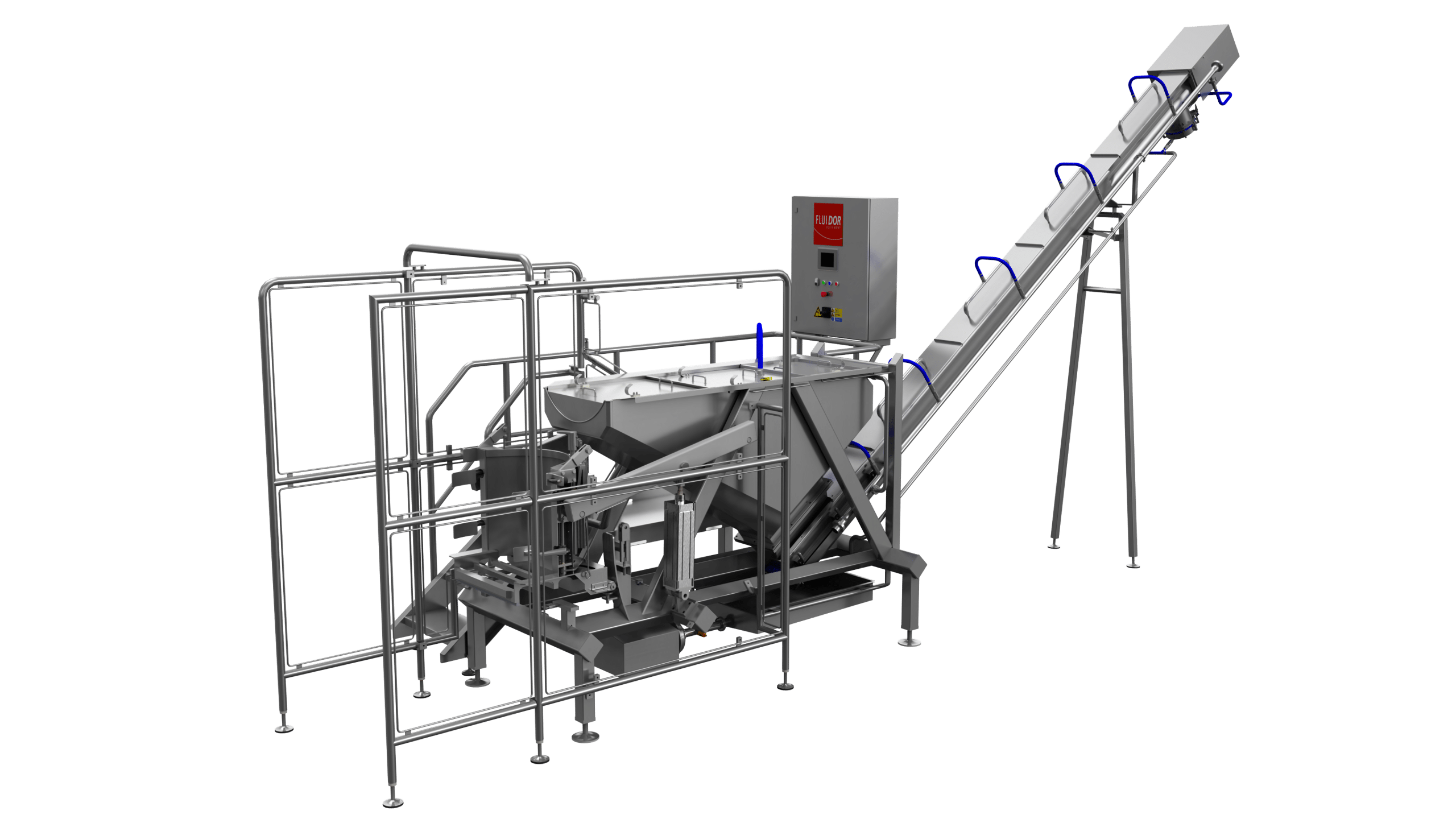

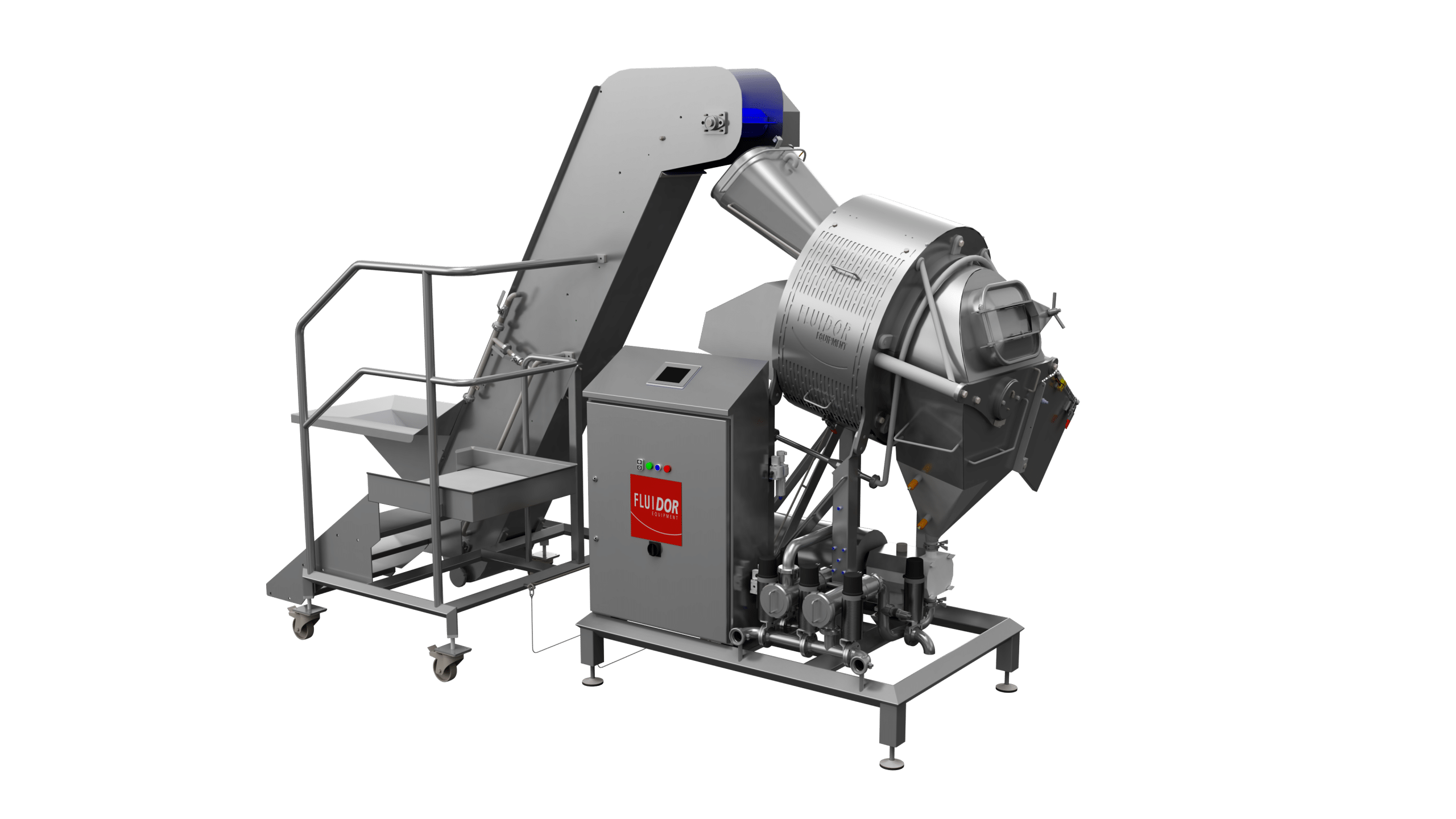

DAPS Drum Dumper

With the DAPS Drum Dumper, you can safely process large quantities of liquids in drums and make your production process more efficient and easier.

Empty drums quickly, efficiently and safely

Does your industry need to transfer liquids from drums to a production process or other storage containers? The Drum Dumper (DAPS) from Fluidor Equipment empties your drums quickly, efficiently and safely.

This machine is designed for an efficient emptying of 200 litre open top drums containing liquid products like fruit juice concentrates (up to 70° brix), with a maximum viscosity of up to 20.000 cP.

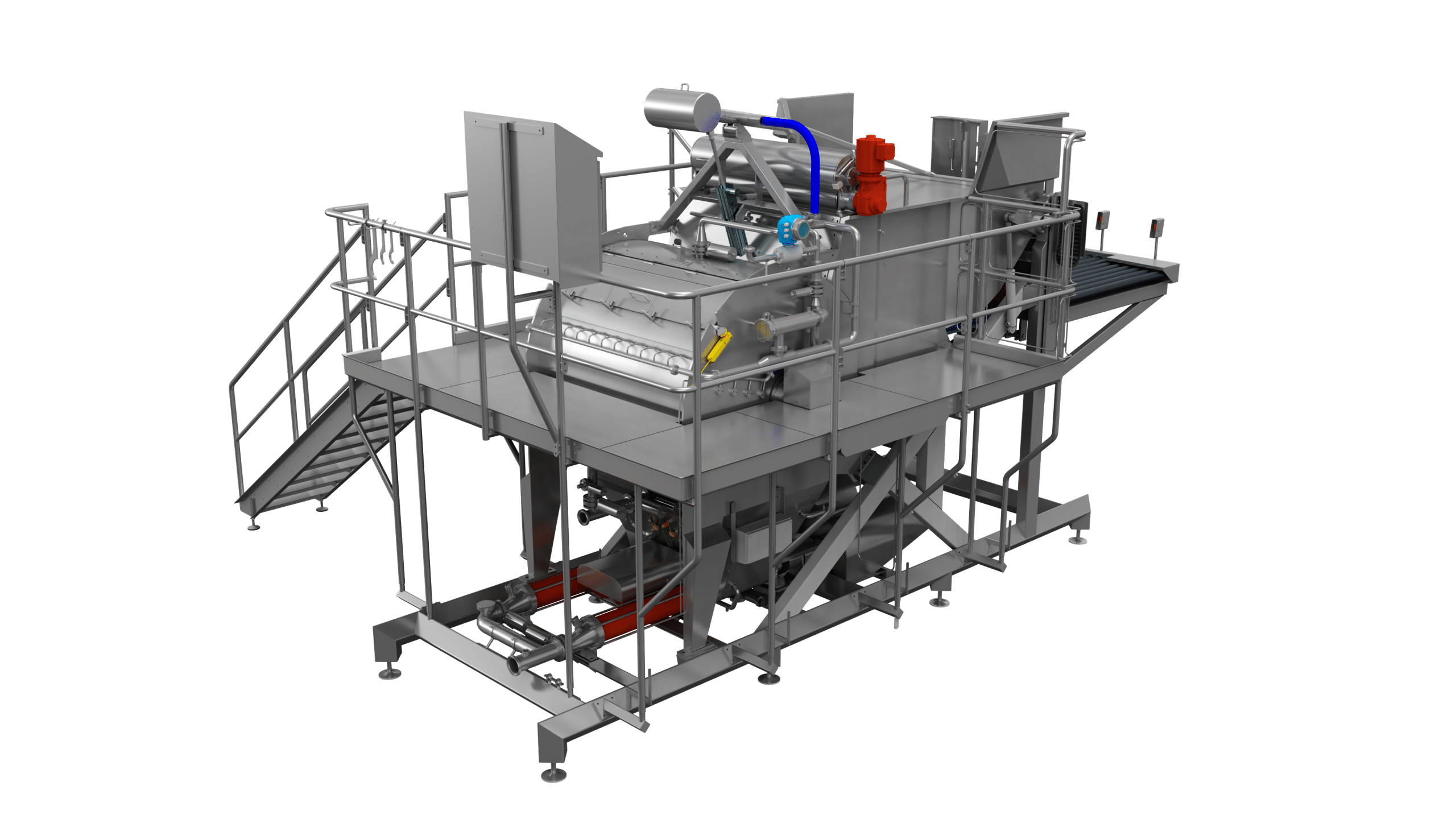

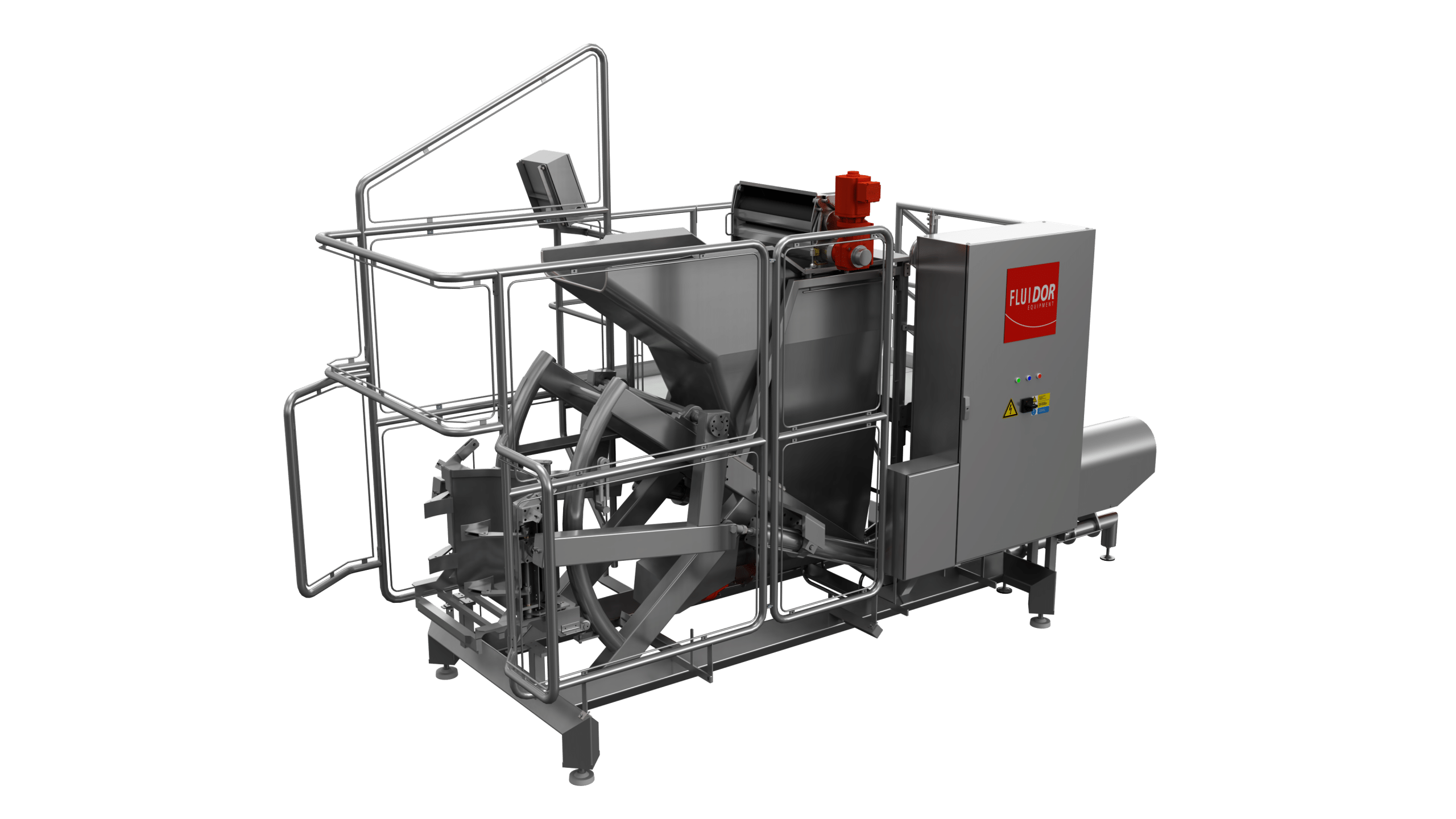

How the DAPS works:

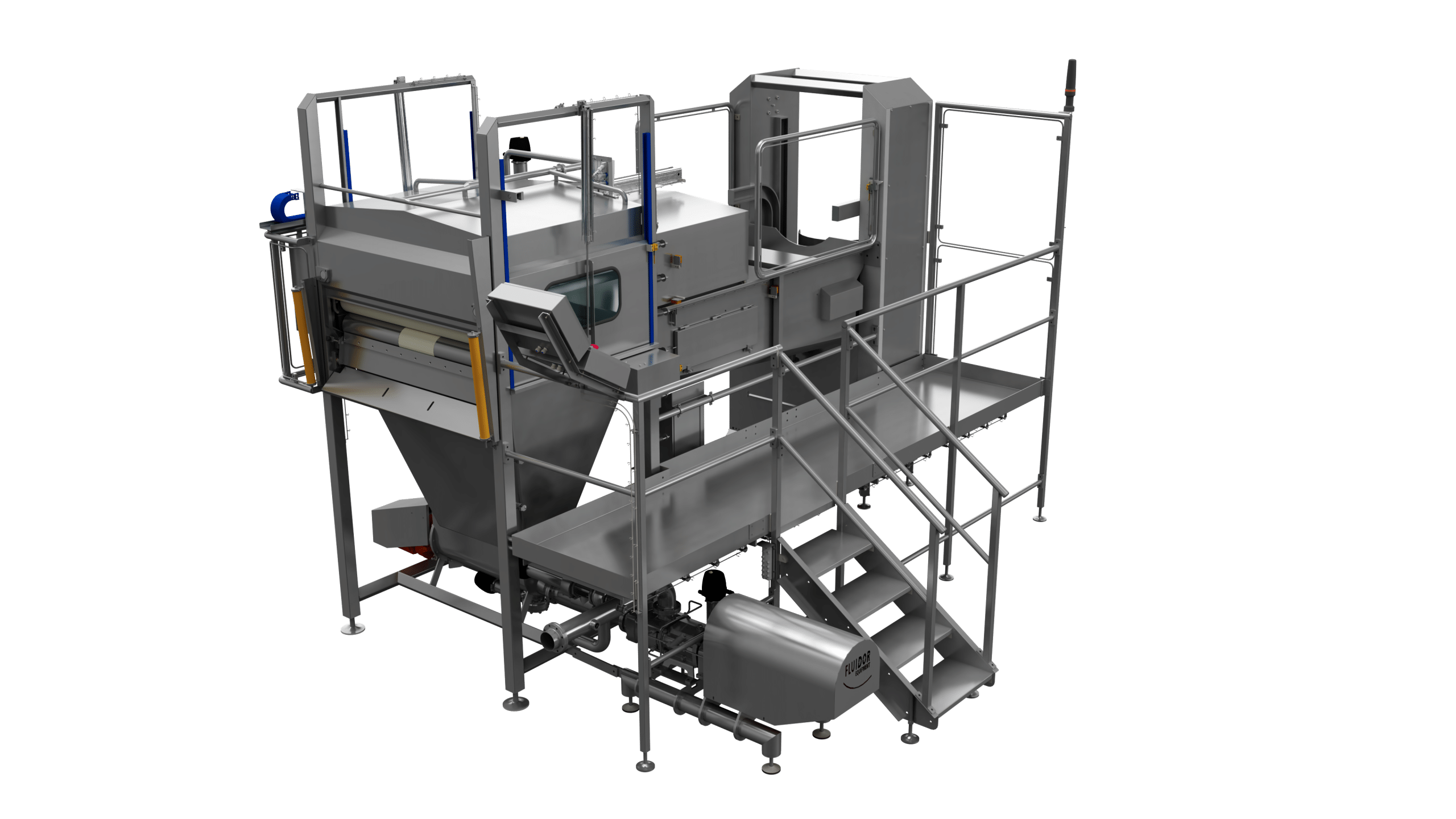

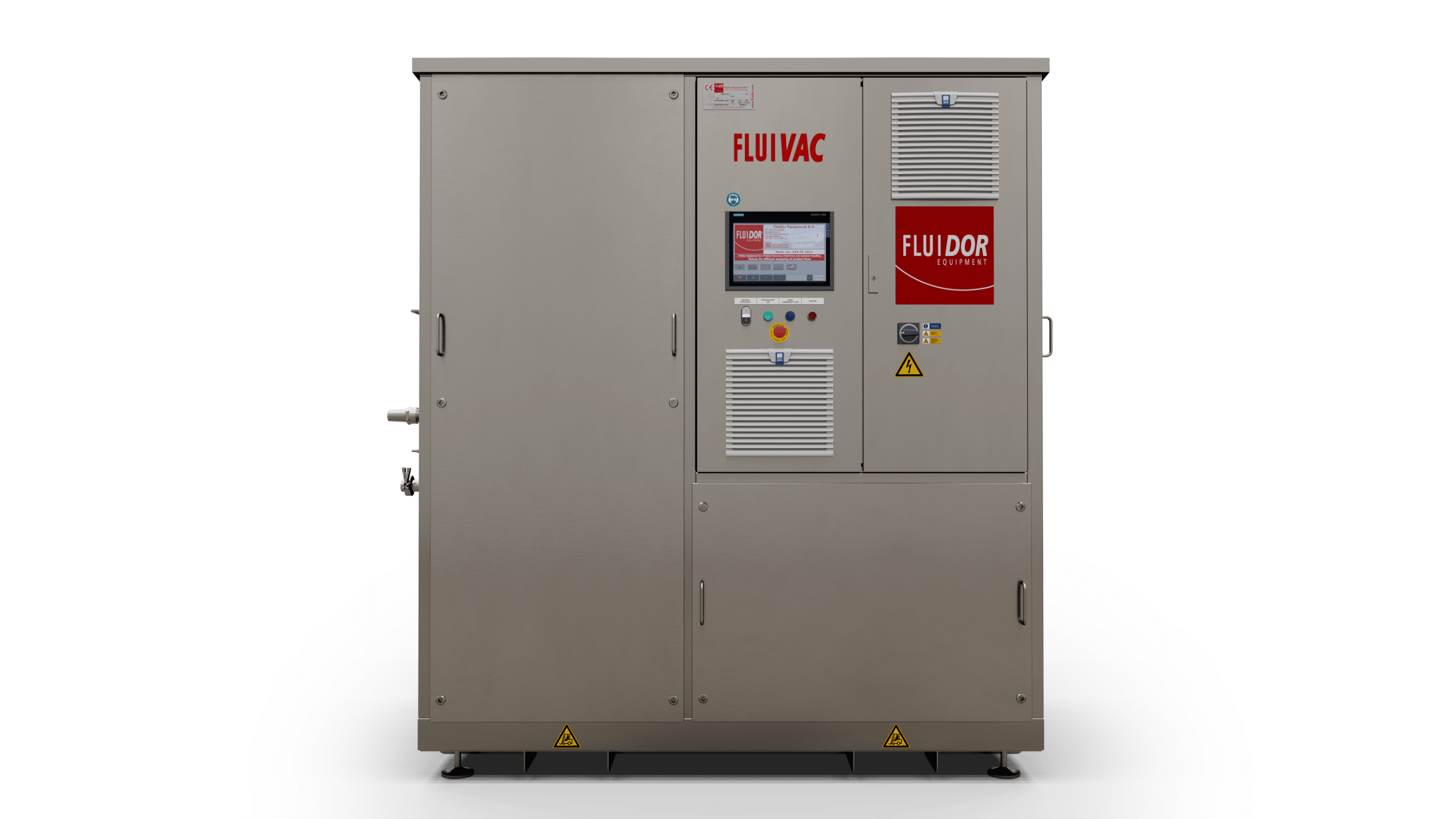

- After production, CIP covers with rotating nozzle can be placed for integration into your CIP process.

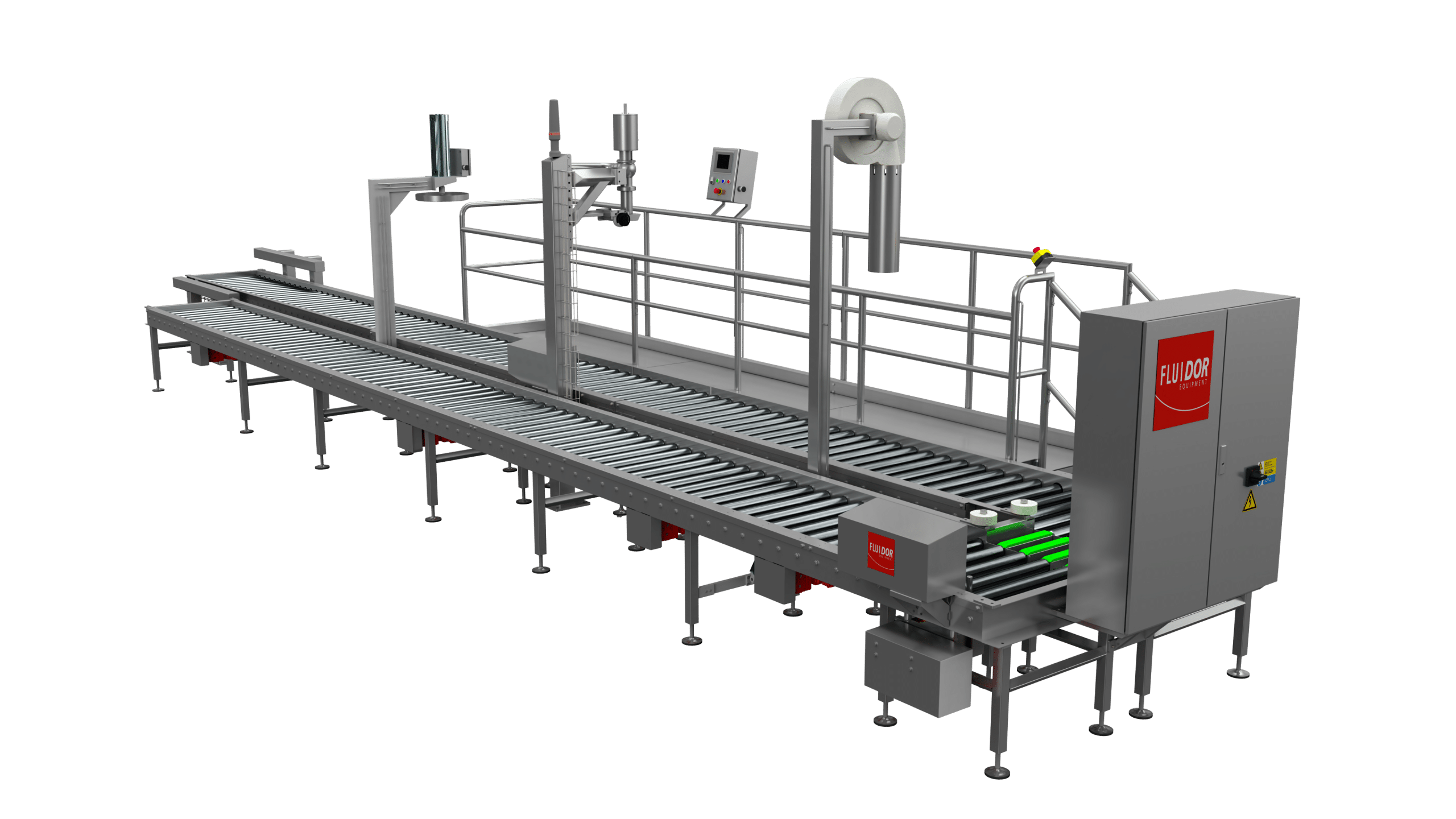

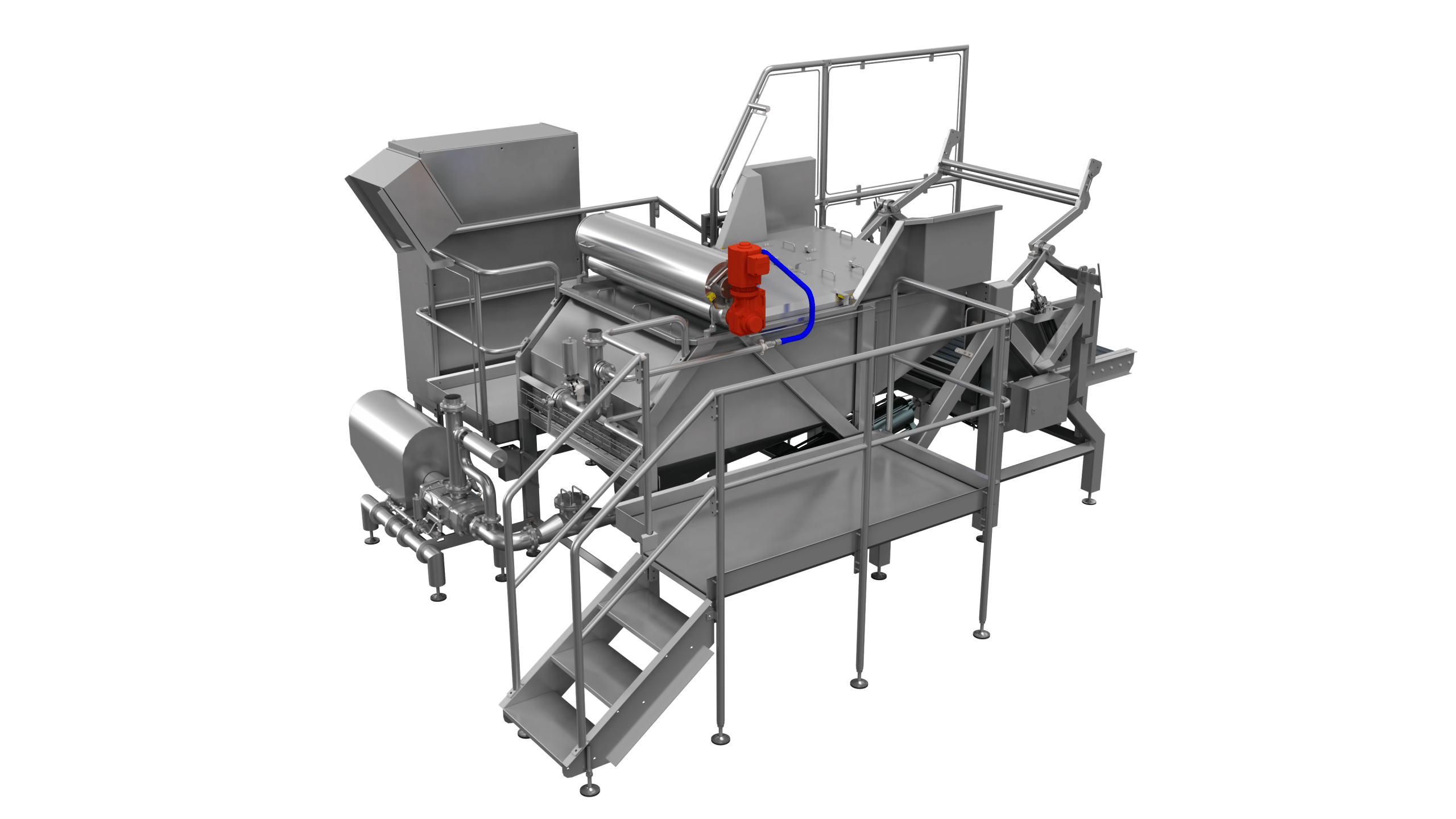

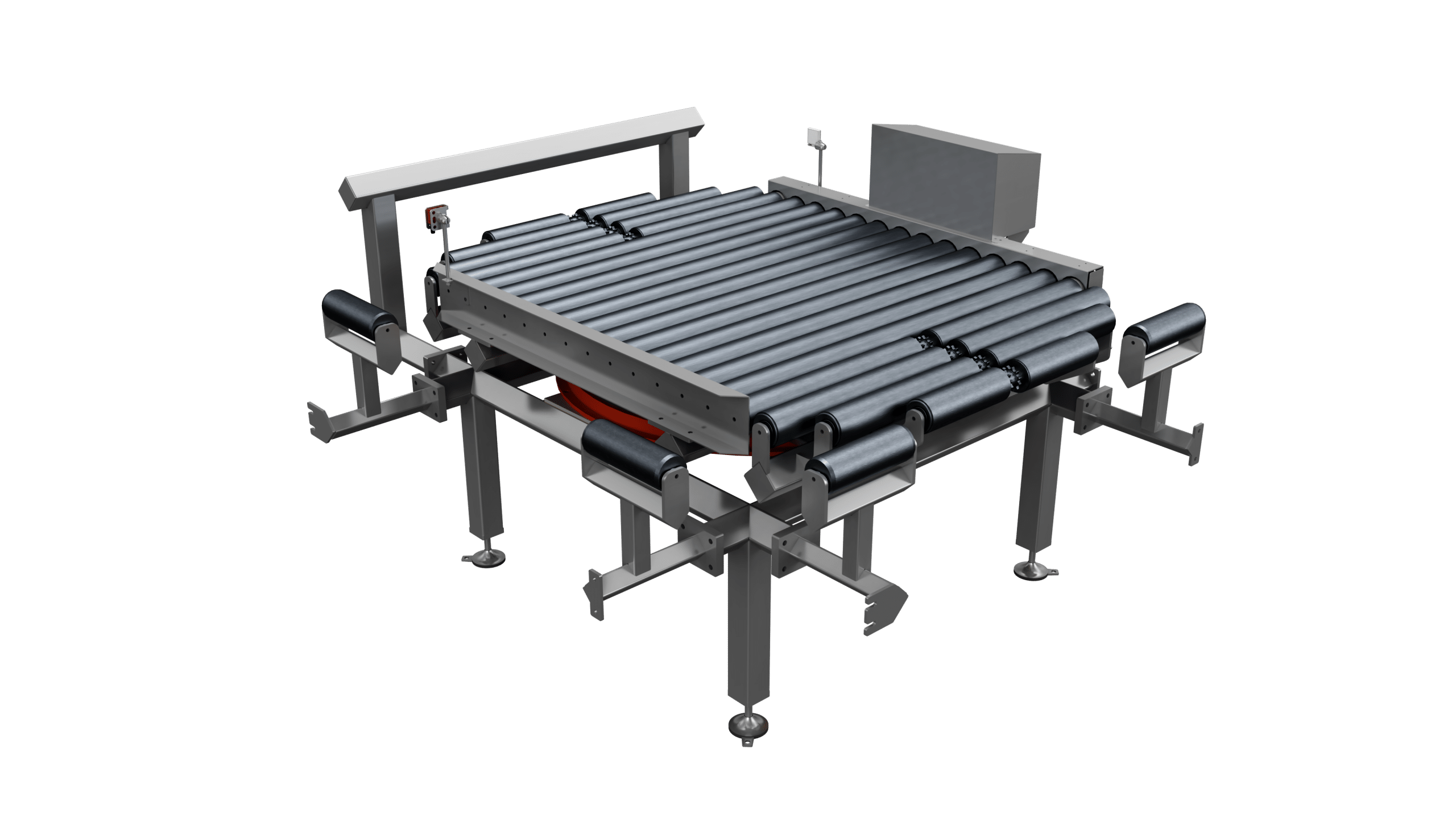

- Drums are placed on the roller conveyor section, at (optional) the drum opening station the lid is removed and the liner(s) are opened.

- The drums are transported to the Drum Dumper, where the drums are lifted and tilted pneumatically.

- The liner with product falls into the collection hopper and is stopped by a grid. The liner will partially empty itself.

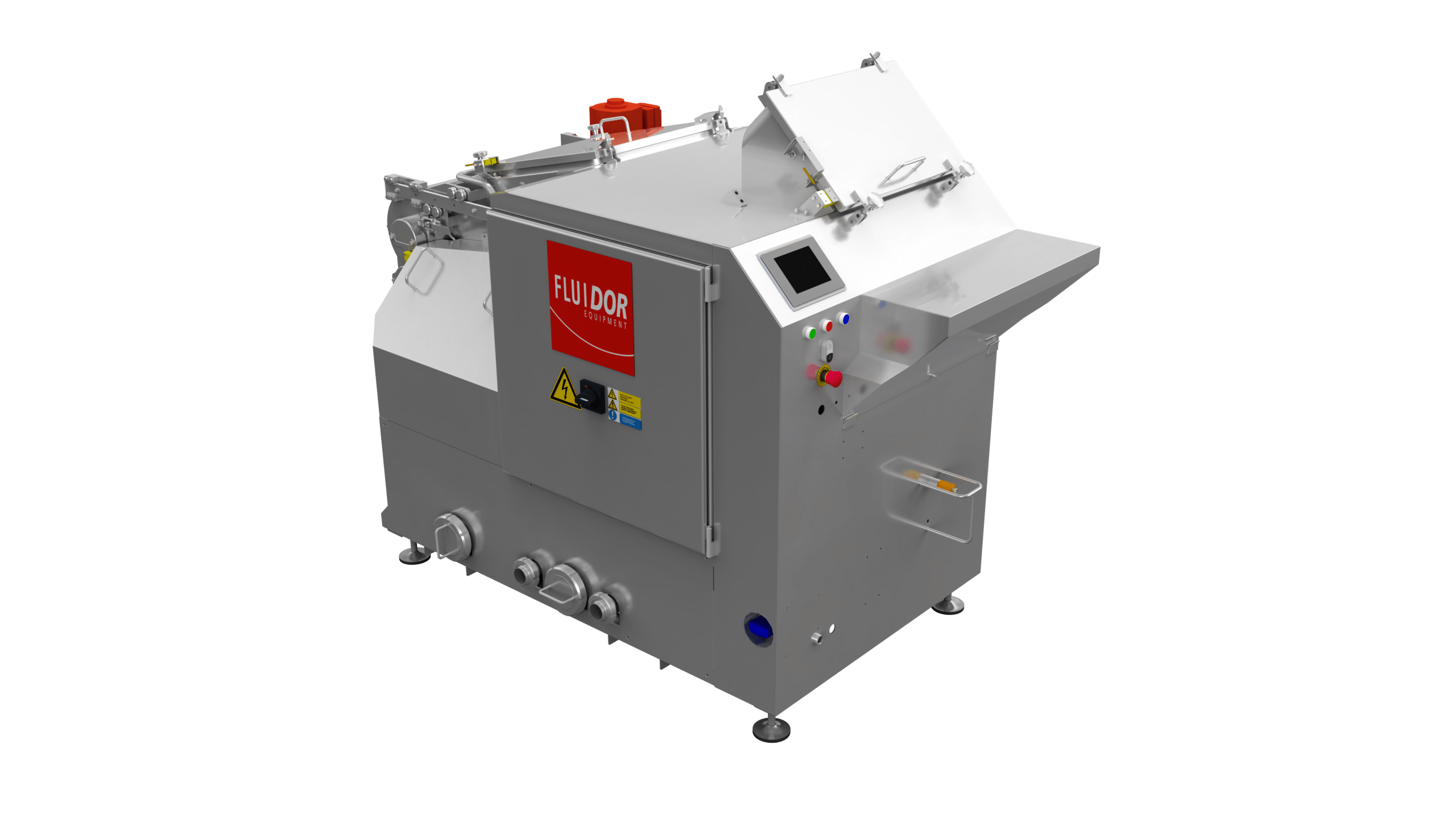

- The operator inserts the lower part of the liner into the squeezer and the remaining product is squeezed out.

- The product flows into the product hopper and is discharged by a twin-screw pump.

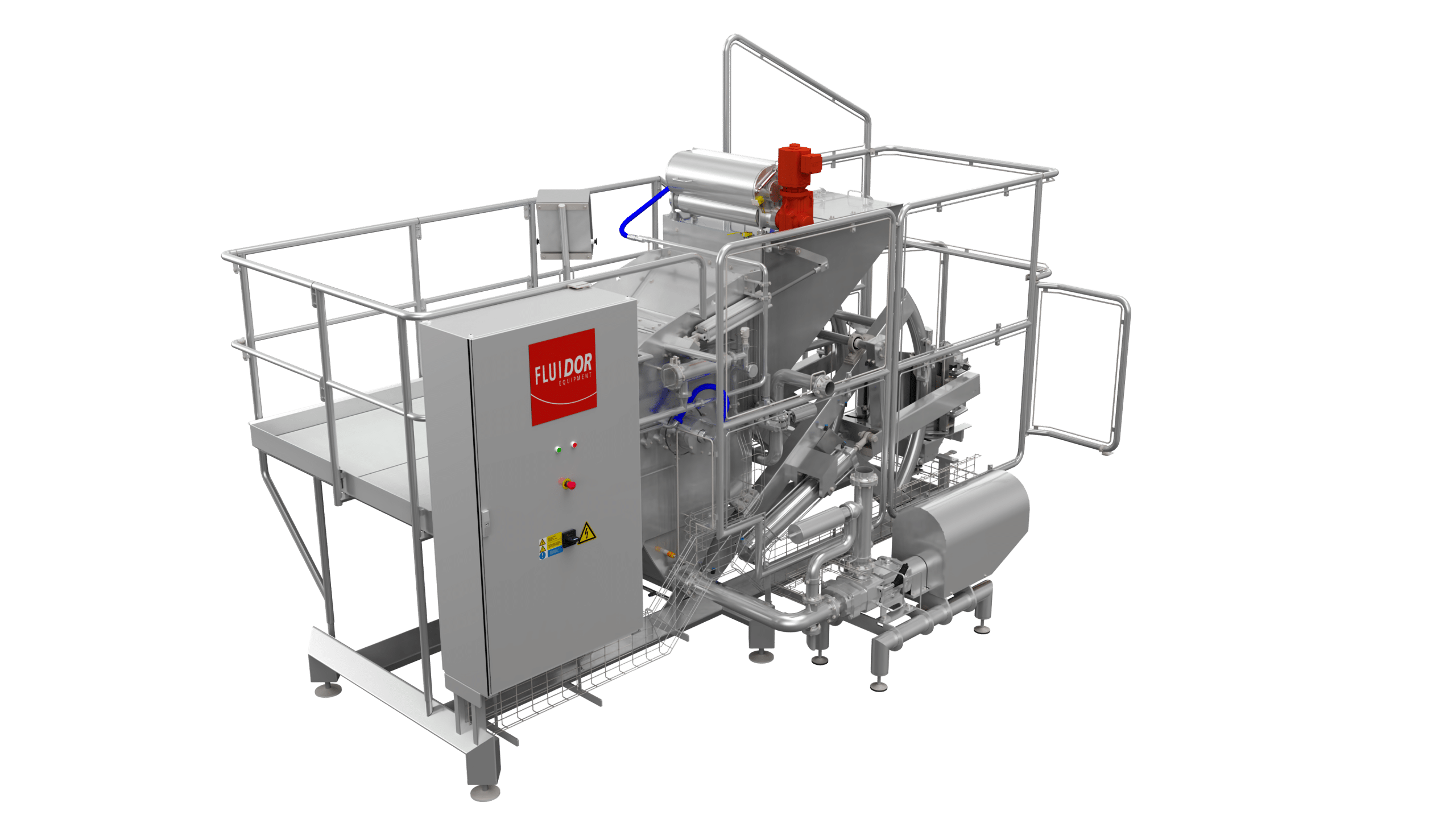

The DAPS is designed to empty the entire drum, which minimises raw material waste. It also ensures fast and consistent emptying of drums, helping to save production time and increase productivity.

The DAPS minimises the risk of spills and accidents, which contributes to a safe working environment. It also reduces the physical burden on employees, as manual lifting and tilting is no longer necessary.

The DAPS Drum Dumper is built to last and requires minimal maintenance. The machine can handle different sizes and types of drums, making it widely applicable in various industries.