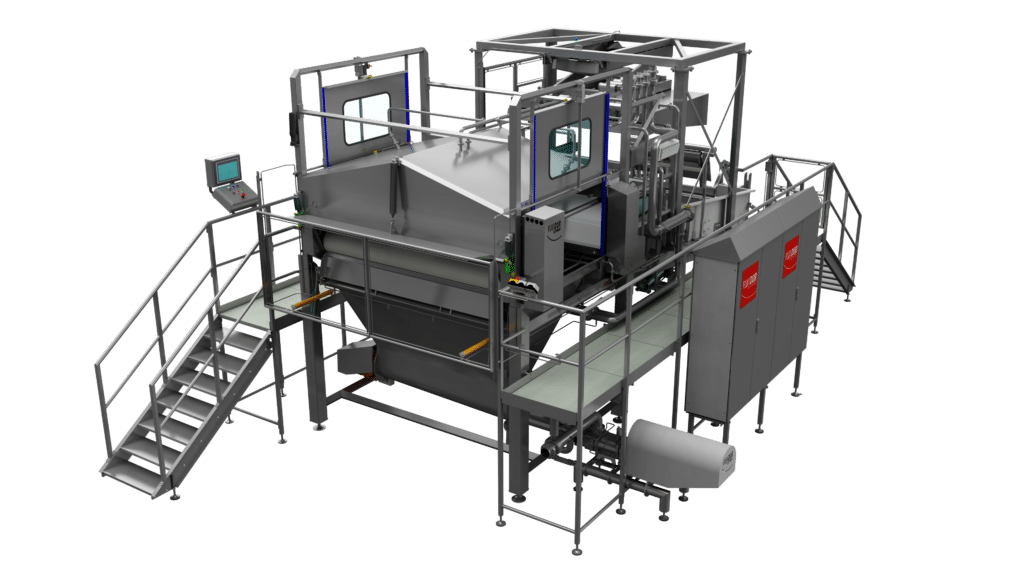

Tote Bin Dumper Paste

With the Tote Bin Dumper Paste (TBD-Paste), you can handle and empty tote bins and drums with paste-like substances efficiently.

Empty tote bins and drums safely and efficiently

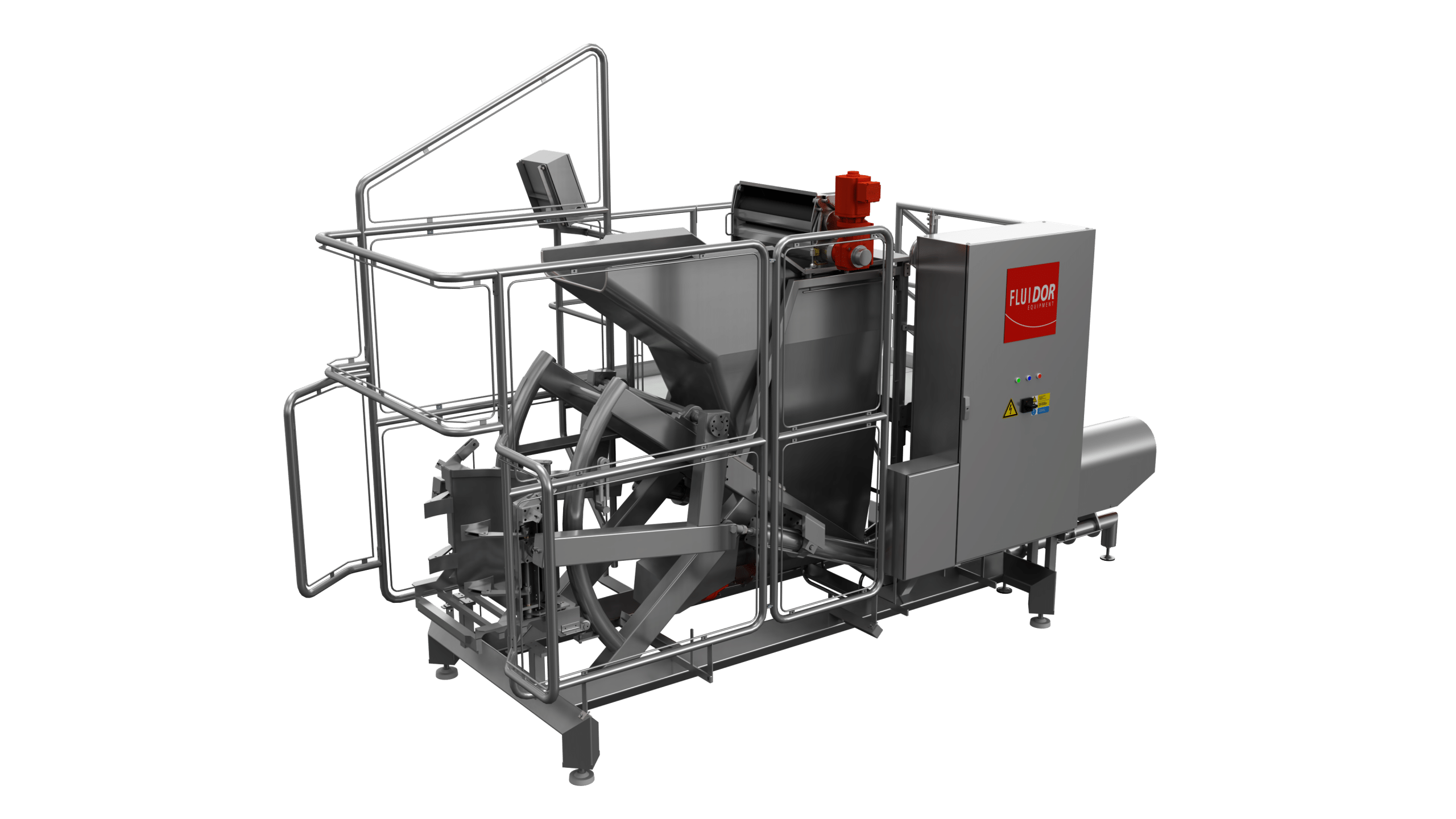

Does your industry require emptying tote bins and drums with thick materials like pastes? The Tote Bin Dumper Paste (TBD-Paste) from Fluidor Equipment is designed for automatic emptying of tote bins and drums with aseptically packed viscous products like Cold Break, Hot Break or Super Hot Break Tomato paste (with press plate).

Depending on the infeed and your product, it can handle up to 20 tote bins or 20 drums per hour.

How the TBD-Paste works:

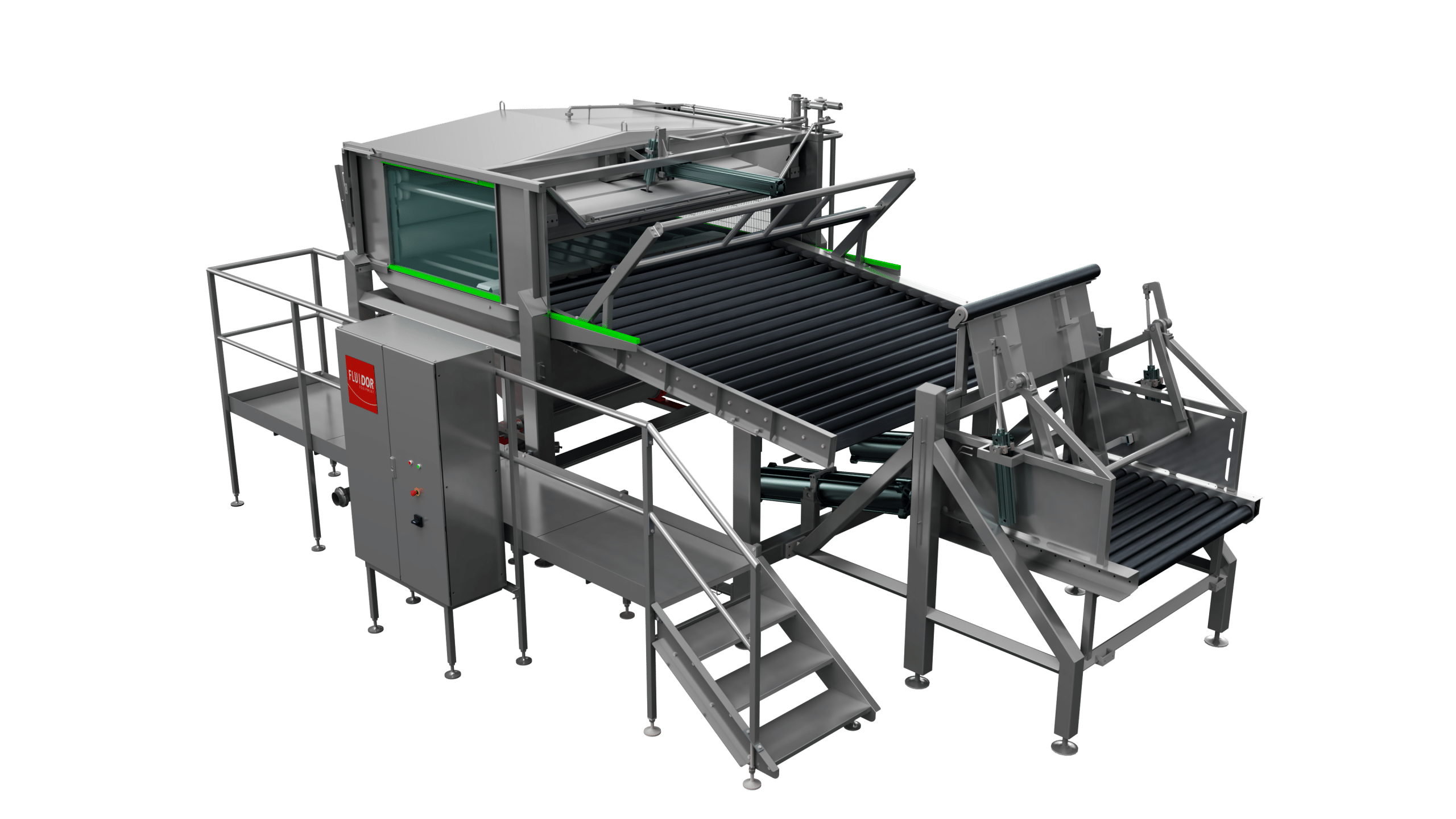

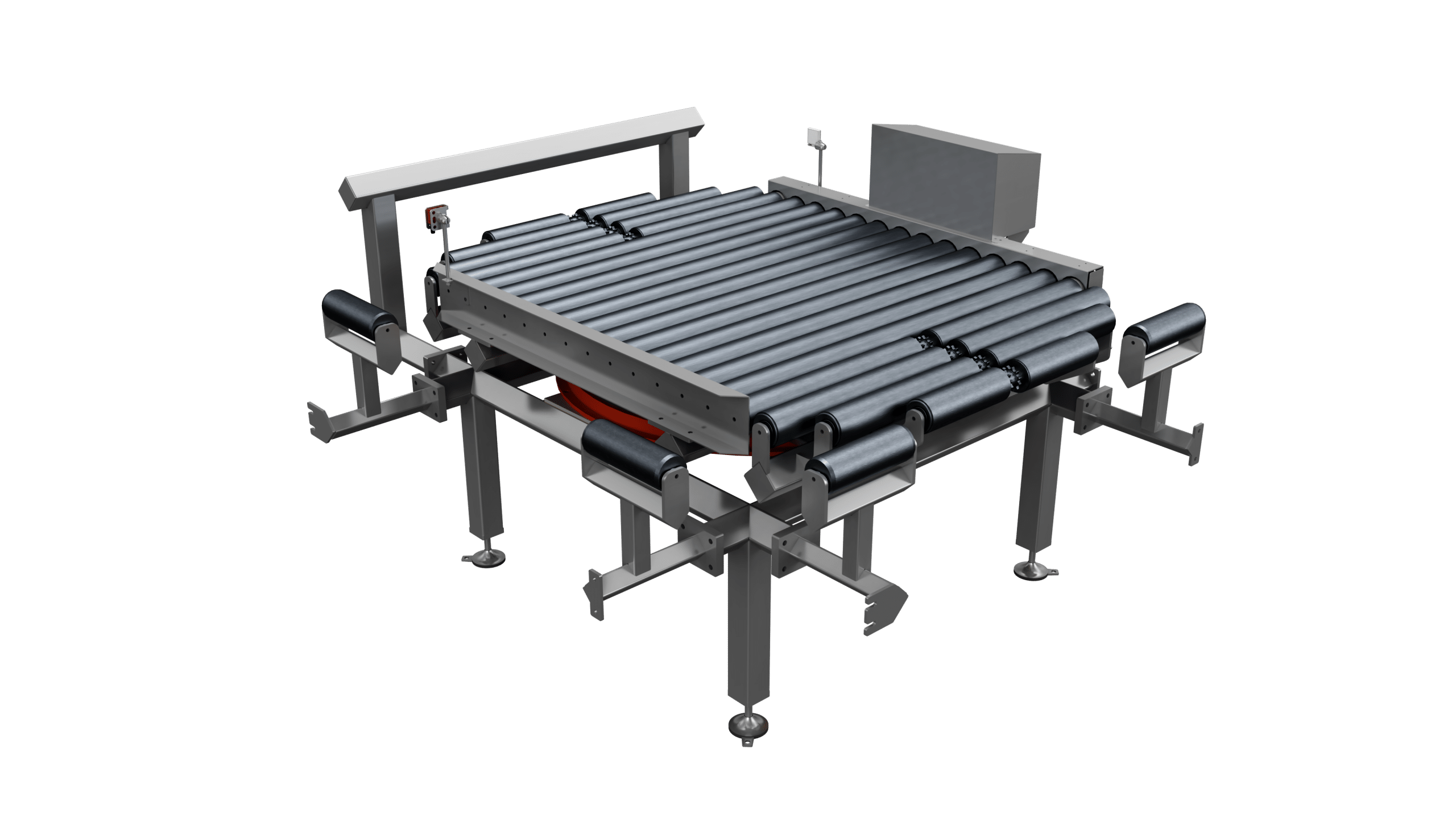

- The bins or drums are transported into the roller conveyor section of the bin/drum holder.

- The bin/drum is clamped and lifted by pneumatic cylinders. At the highest tilting point, the aseptic bag falls out of the bin/drum and spreads out on a stainless steel wire belt.

- The electric driven press plate lowers and flattens the aseptic bag (option for Super Hot Break).

- The wire belt transports the closed aseptic bag through the washing tunnel, provided with a set of spray-nozzles to clean all sides of the bag with high pressure. The cleaning water is collected and drained.

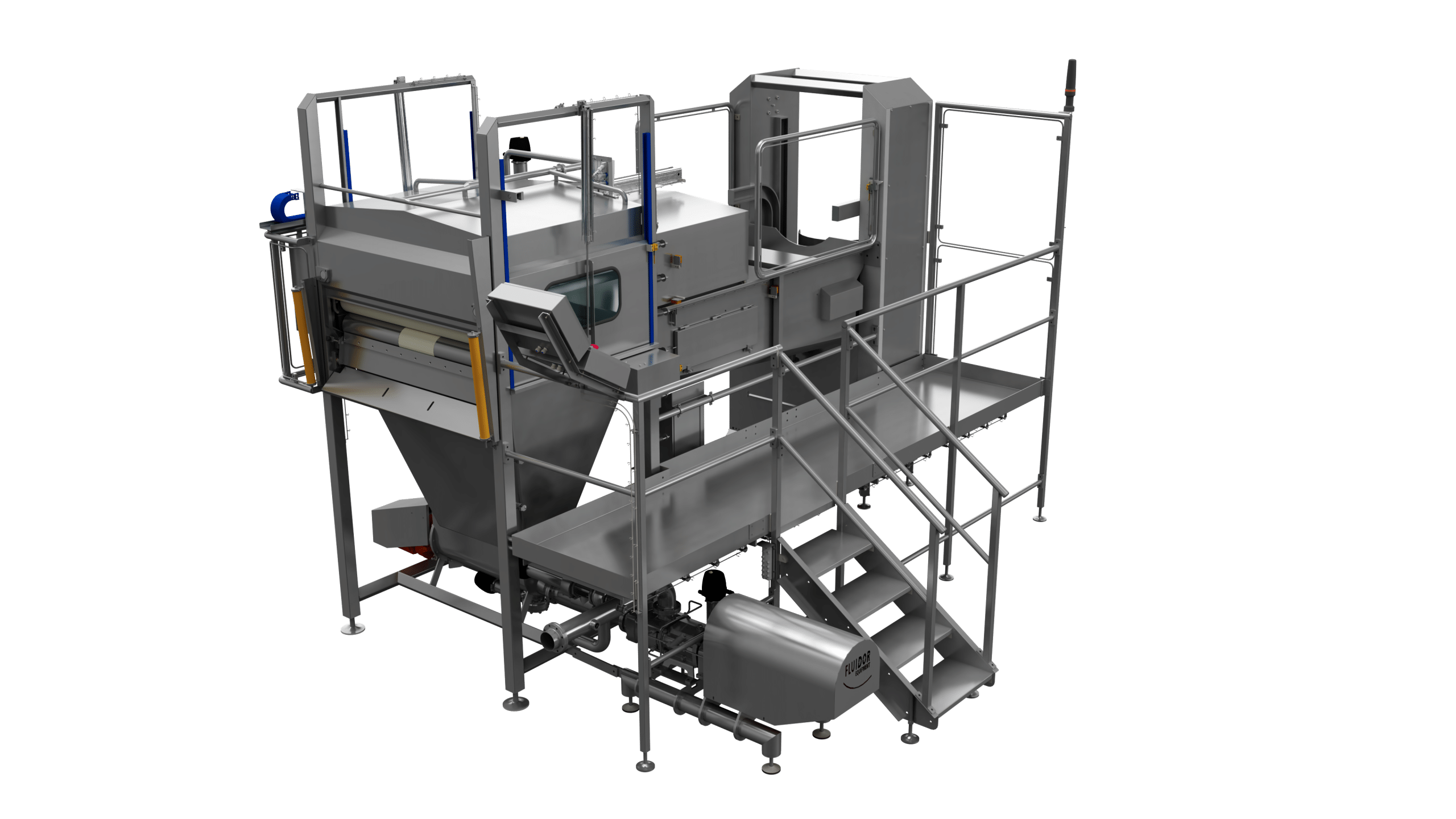

- Above the product hopper, the aseptic bag is automatically grabbed by the bag squeezer. A pneumatic cylinder pulls the bag squeezer over the driven knives that cut the bag open at the bottom side and the tomato paste flows into the product hopper.

- The aseptic bag is emptied completely by the bag squeezer, reducing the loss to a bare minimum (<0,1%). The empty bags are collected in a waste container at the outlet side of the machine (not in scope of supply).

- At the bottom of the hopper, a driven screw conveyor pushes the product into the external twin screw product pump for the next process step.

- After production and short manual pre-cleaning, the C.I.P. covers can be closed and the C.I.P. cleaning with an integrated set of nozzles can be started.

Due to variation in quality (hardness) of the poly liner filler caps, which cannot be influenced by Fluidor and can differ per (bag)supplier, there is a possibility that filler caps from certain bags can break during squeezing, which may lead to pieces of plastic ending up in the product. Fluidor offers a solution for this with transfer caps.

The TBD-Paste is versatile, capable of handling a wide range of paste-like substances across various industries.

The TBD-Paste improves workplace safety by minimising the risks associated with manual handling, ensuring a safer environment for operators.

The TBD-Paste enhances operational efficiency by automating processes for handling and transferring paste-like materials.