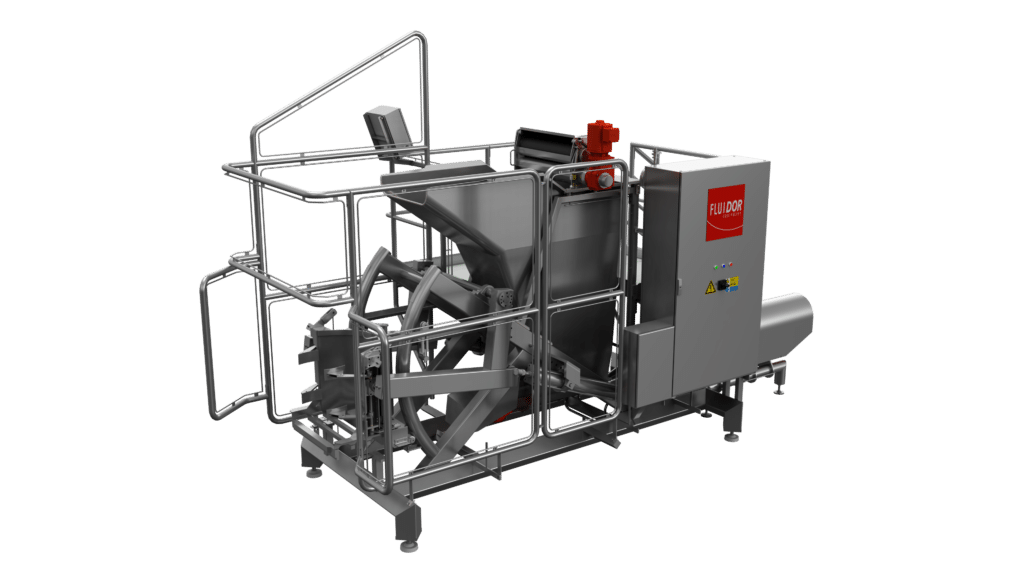

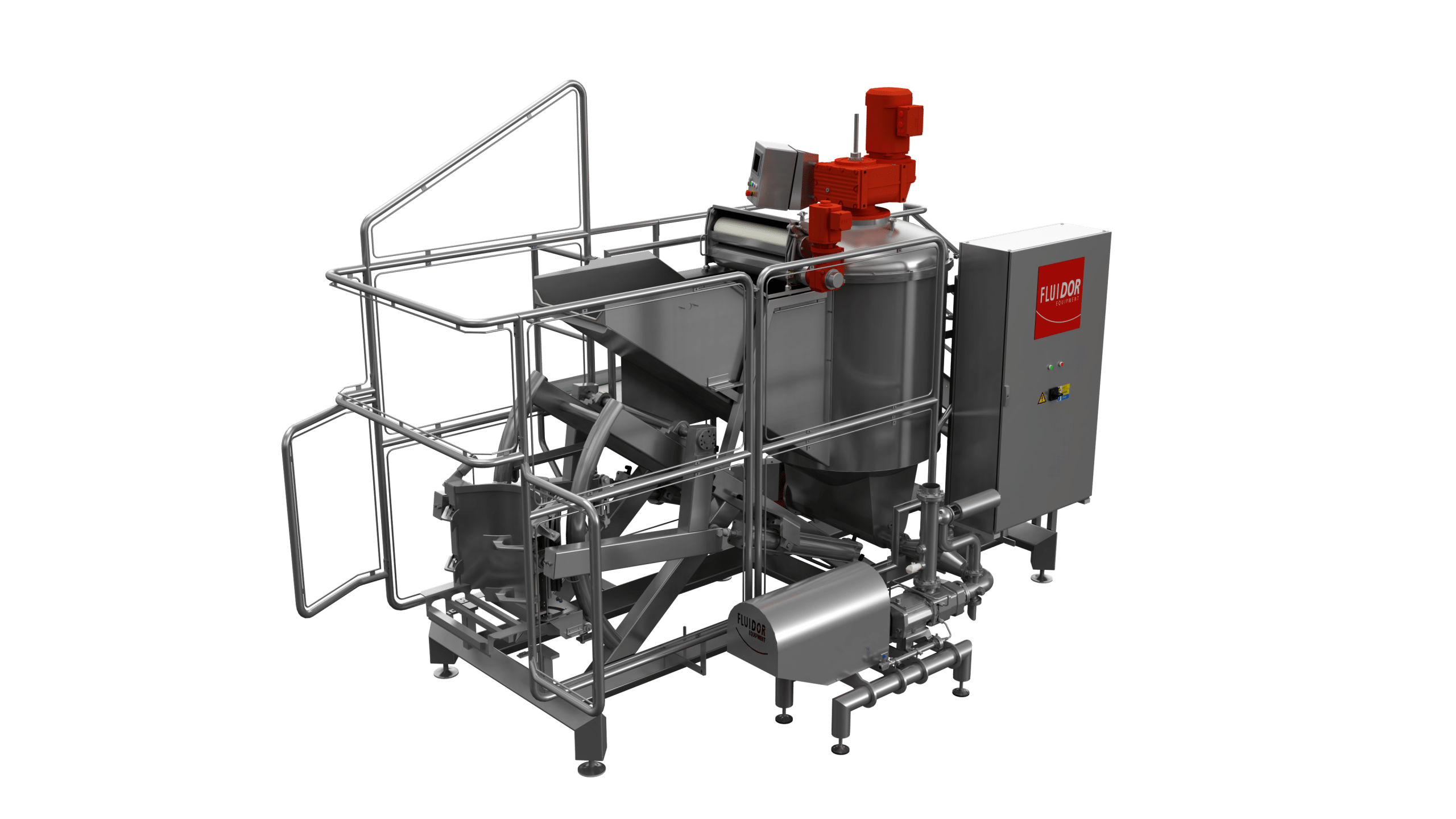

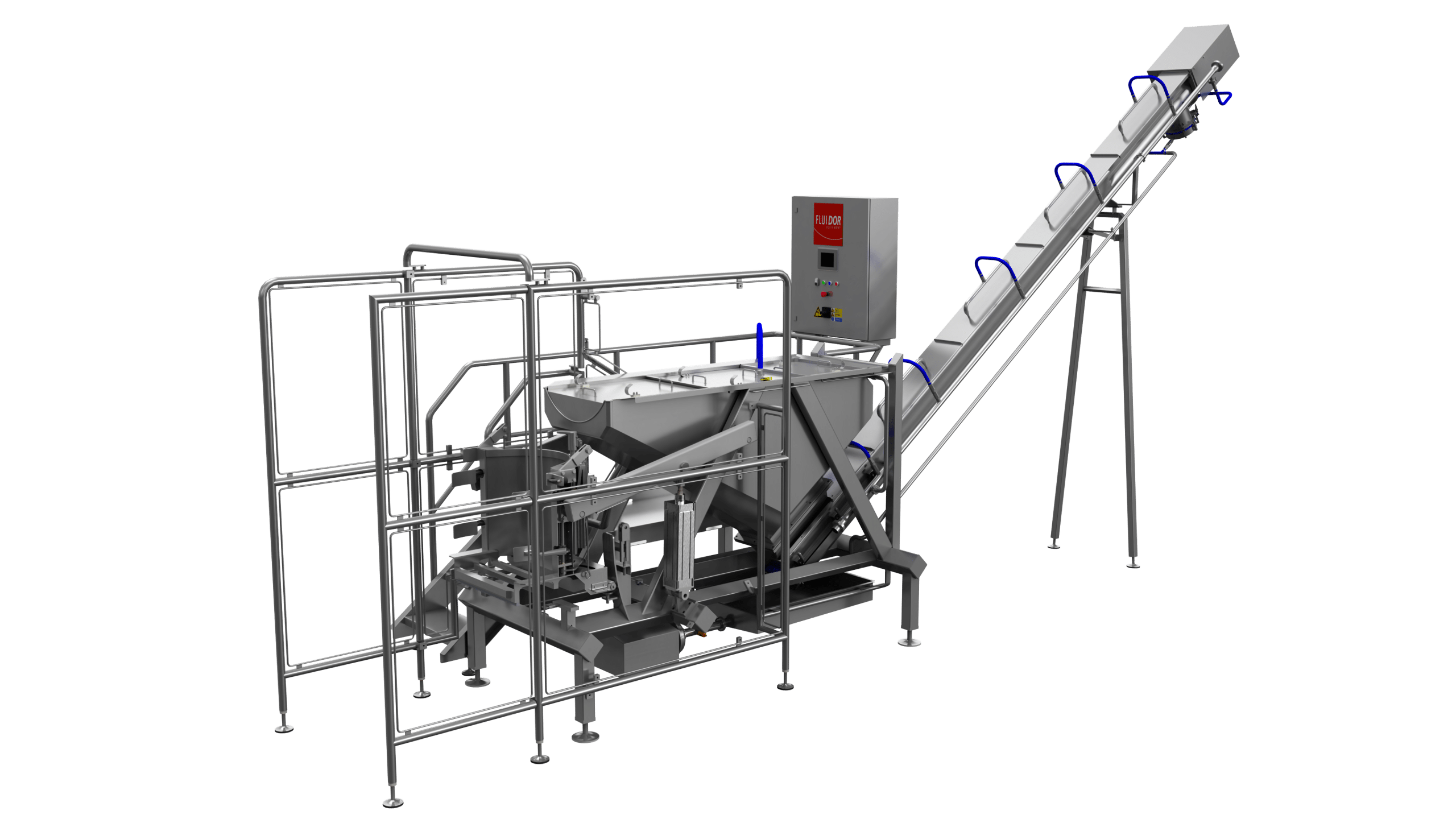

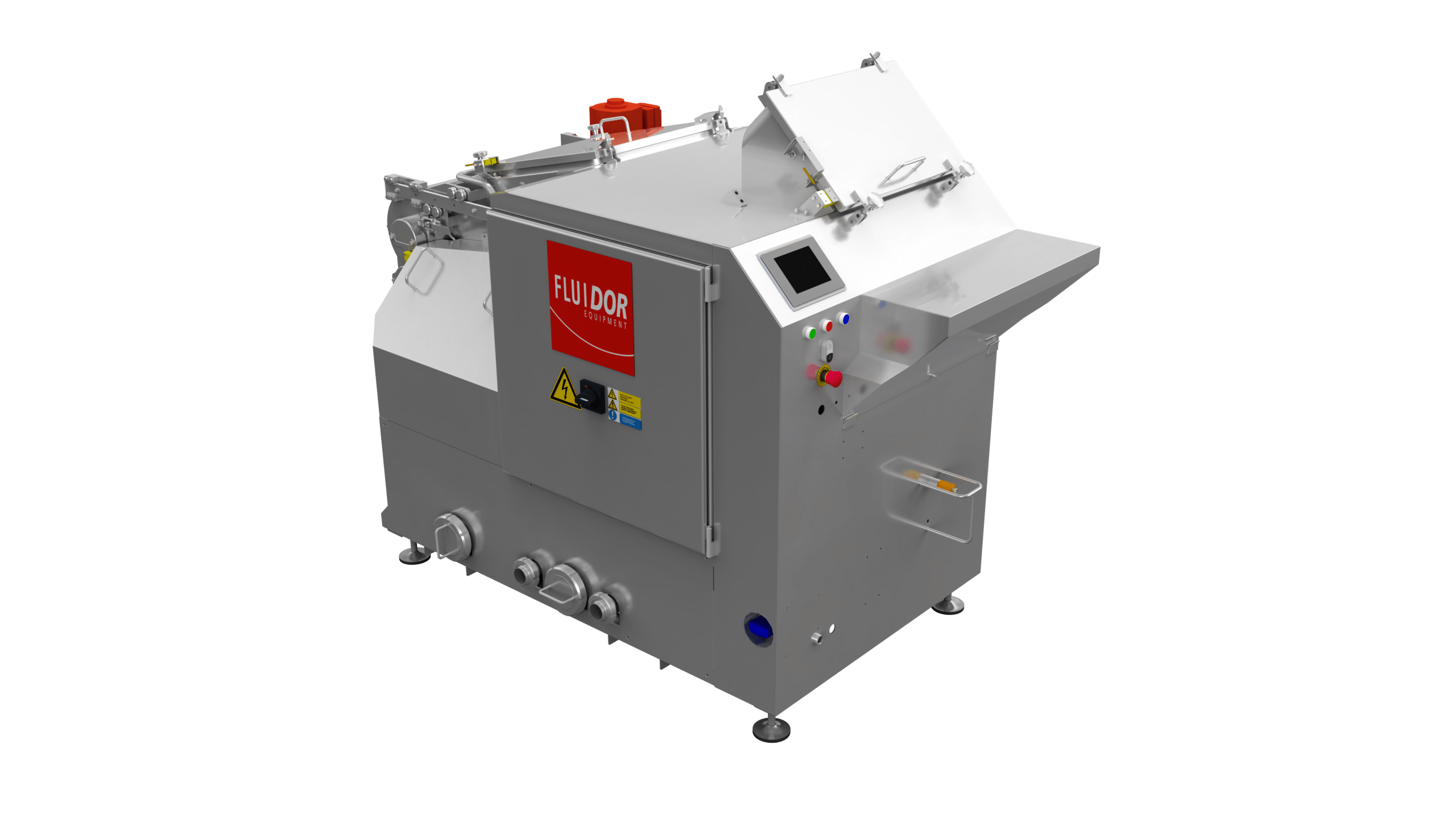

Drum Dumper DAPS Paste

With the Drum Dumper Paste (DAPS Paste), you can efficiently handle and empty drums containing pasty or viscous substances.

Empty drums quickly, safely and efficiently

Does your industry require transferring thick materials like pastes from drums to production processes or storage? The DAPS-Paste from Fluidor Equipment is designed to empty your drums quickly, safely and efficiently.

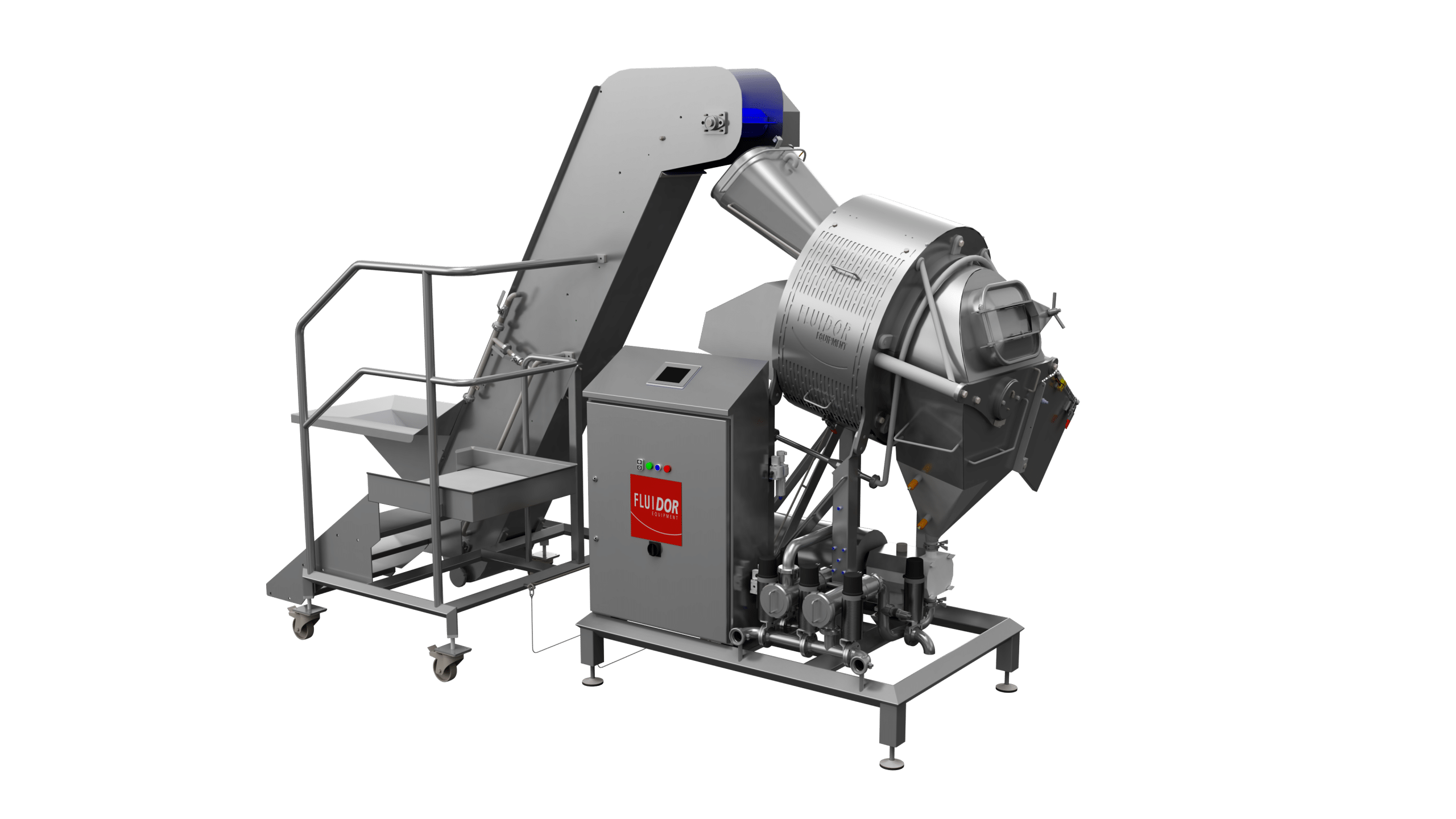

The Drum Dumper DAPS-Paste is designed for an efficient emptying of 200 litre open top drums containing viscous products (up to 38° brix) with viscosity up to 25.000 cP.

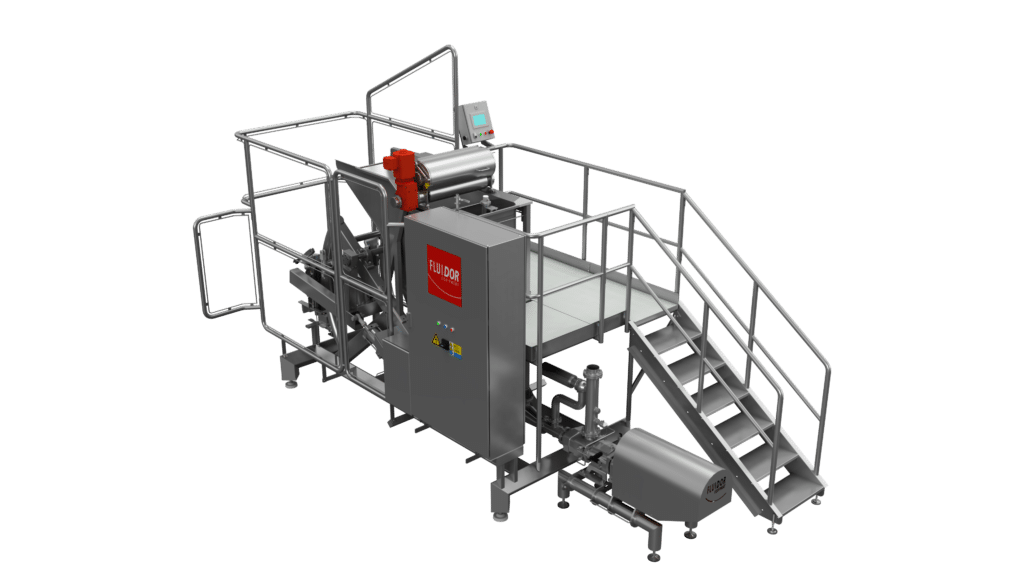

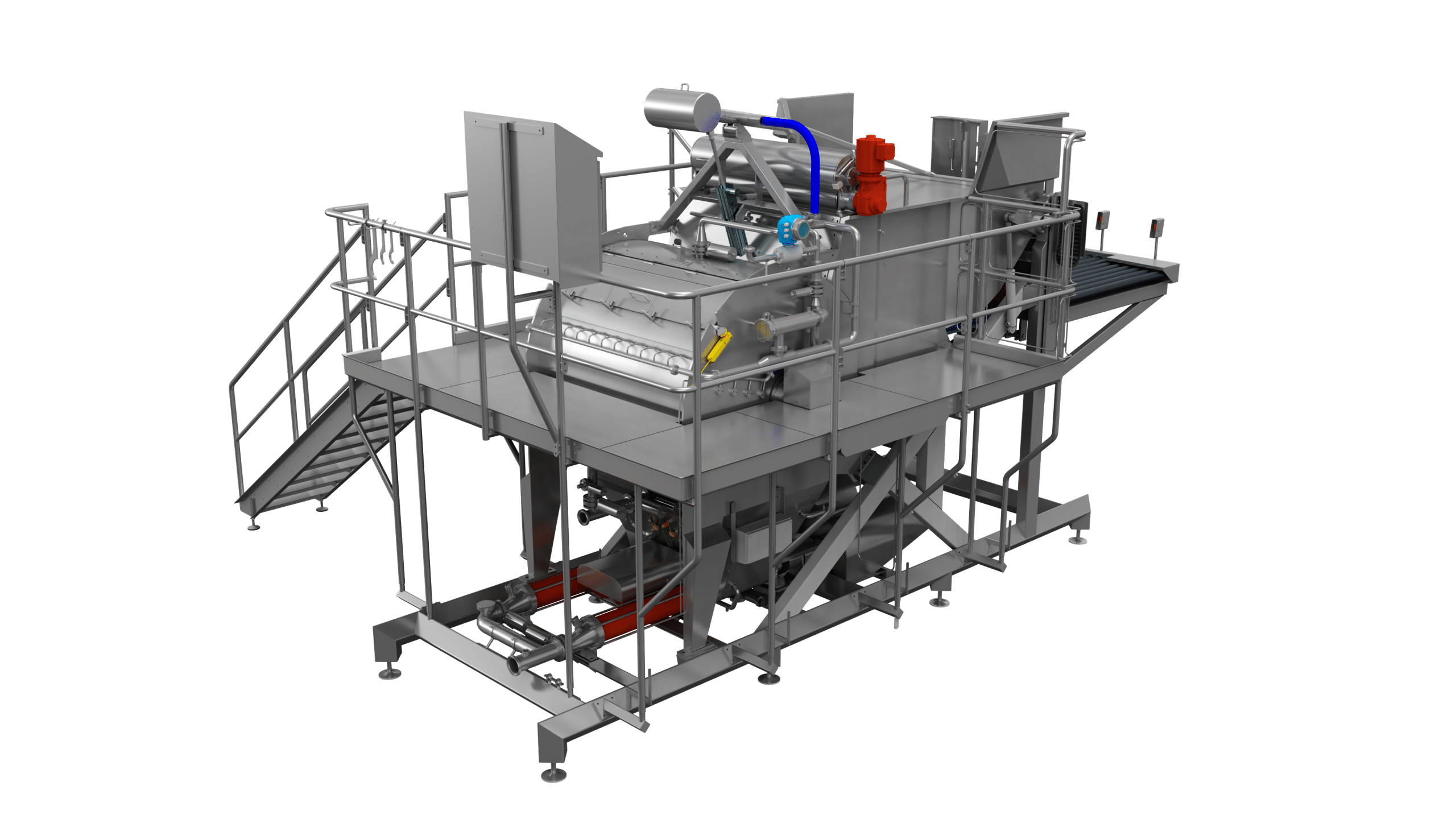

Depending on the infeed and your product, it can handle up to 40 drums per hour.

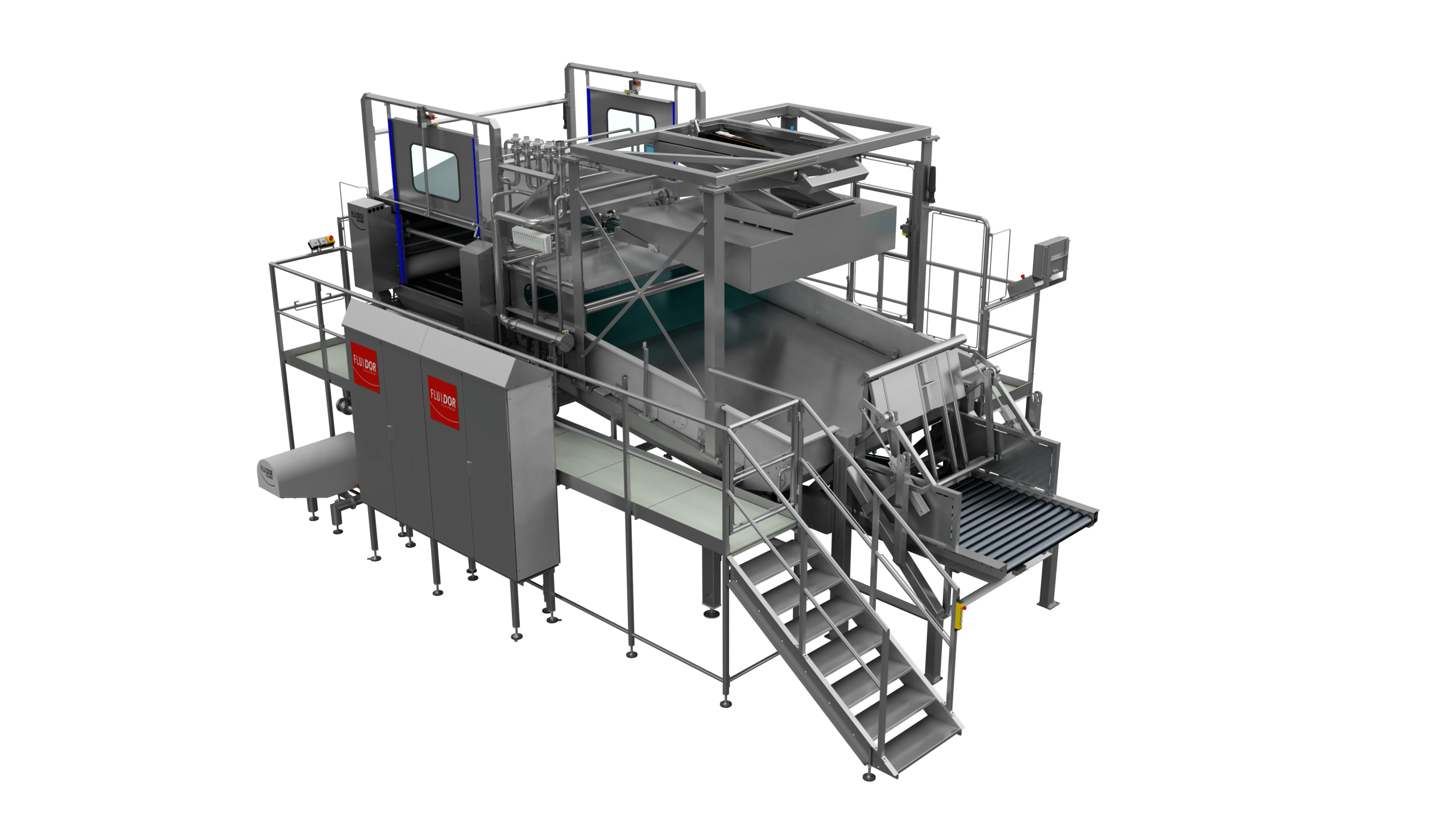

How the DAPS Paste works:

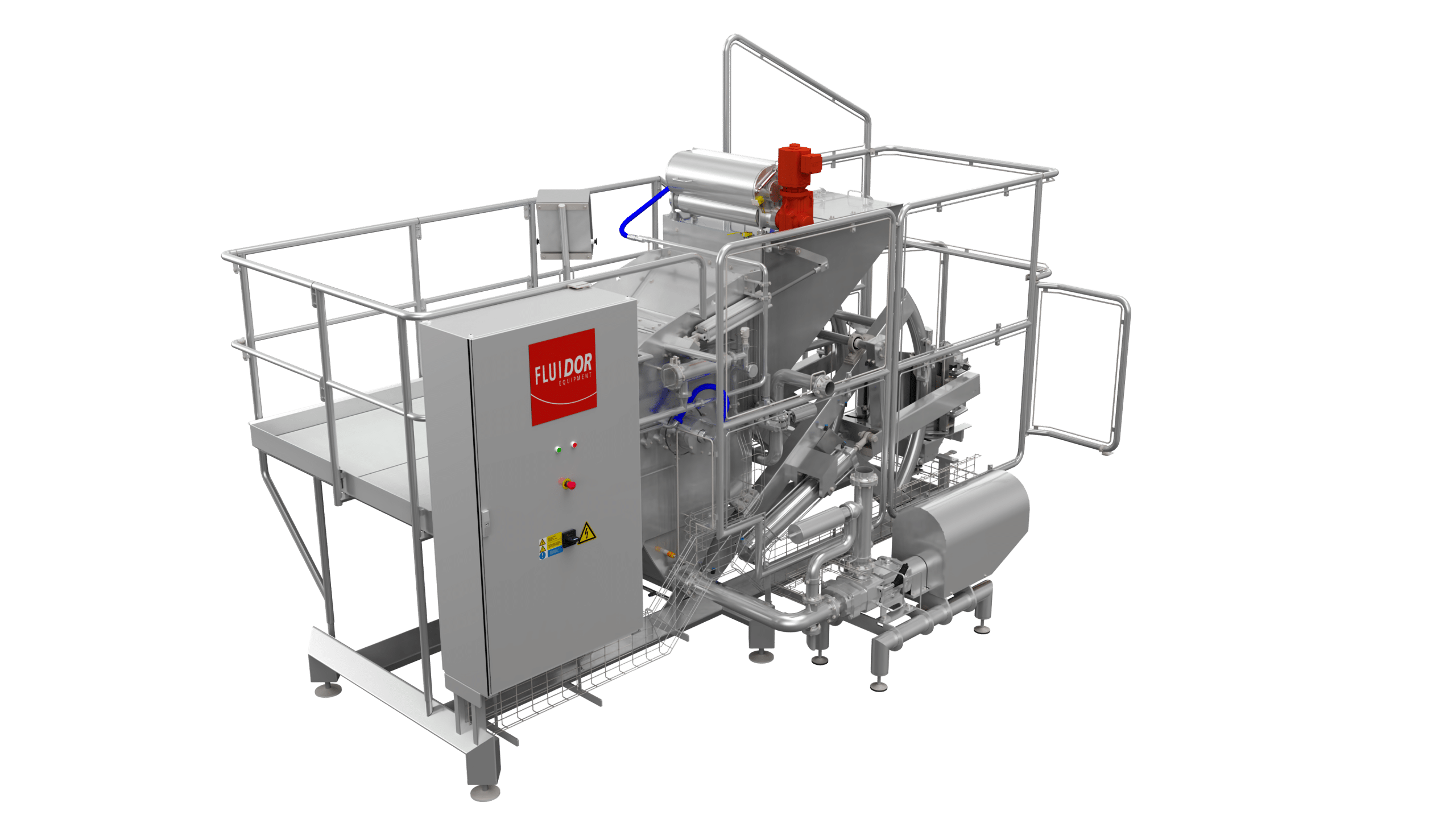

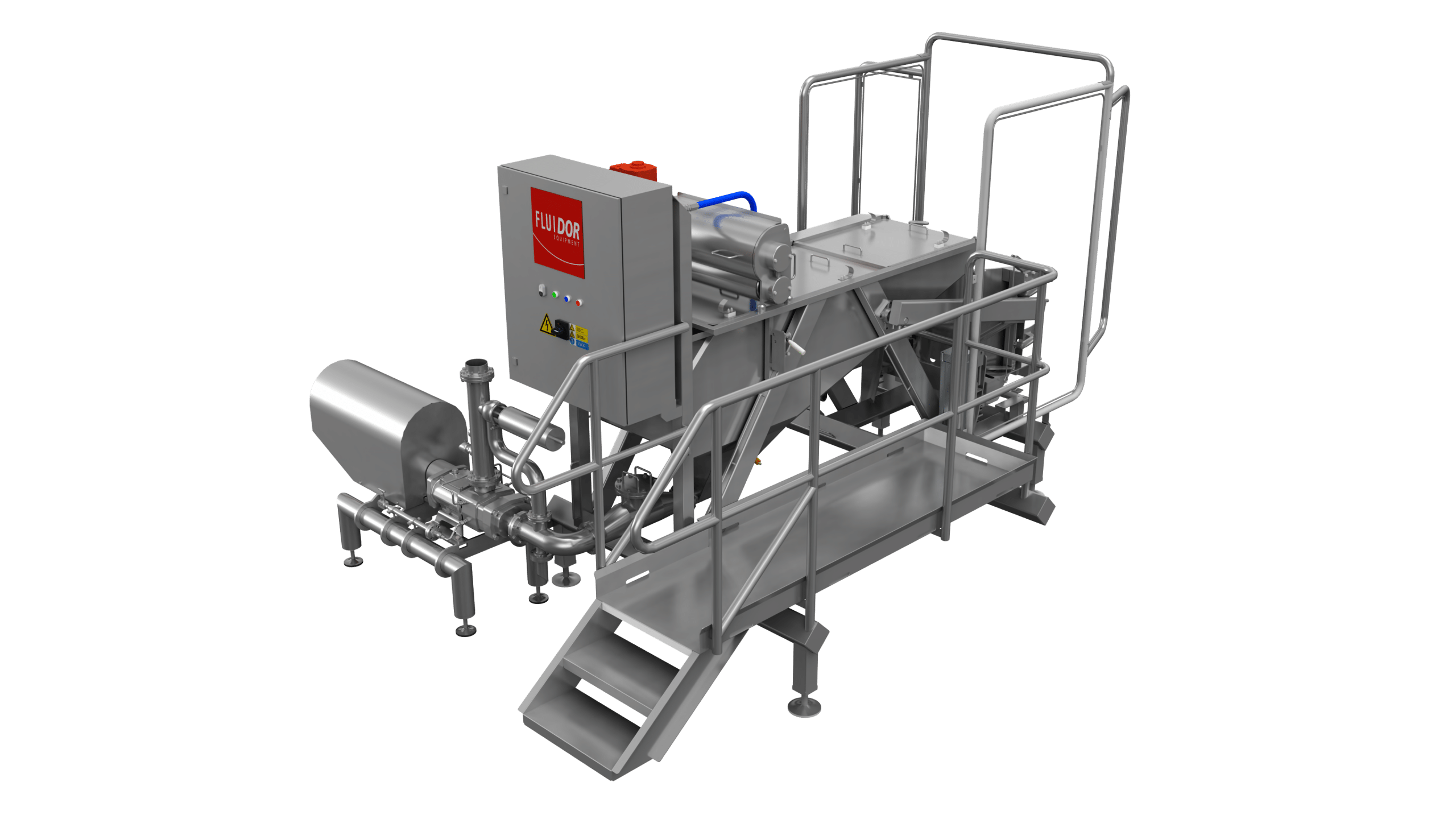

- After production, the CIP-covers with rotating nozzle can be placed for integration of the DAPS-Paste into your CIP process.

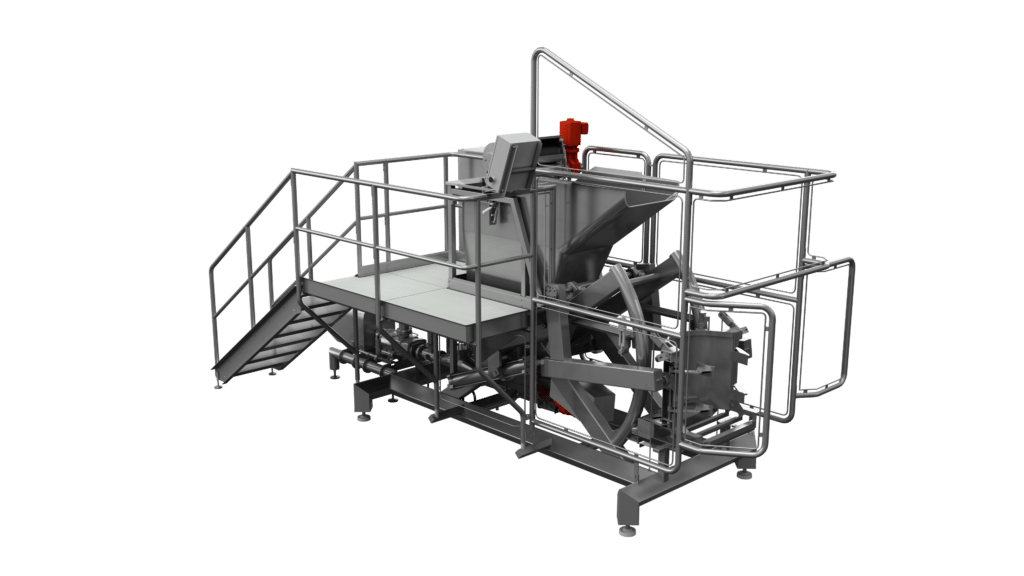

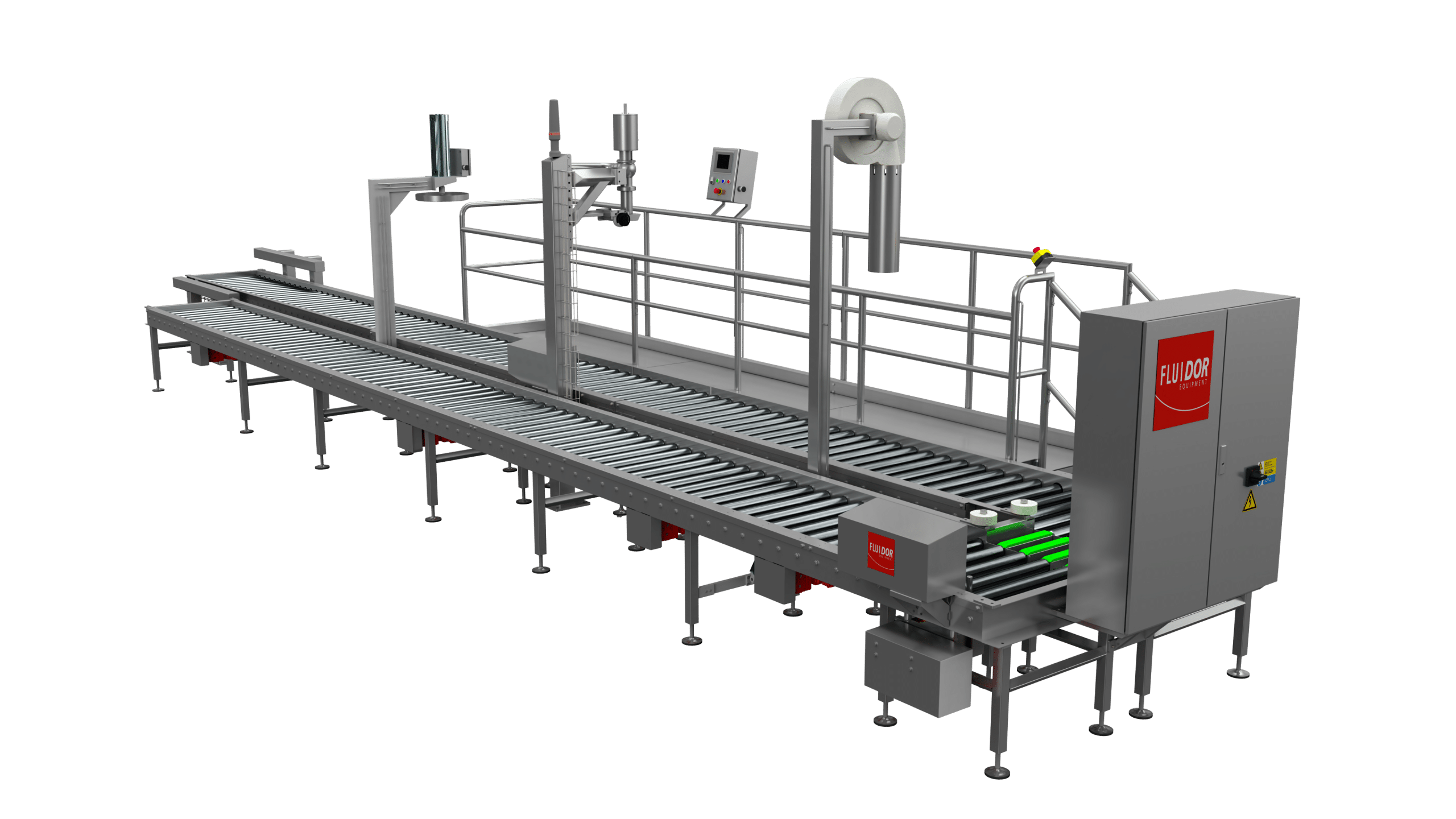

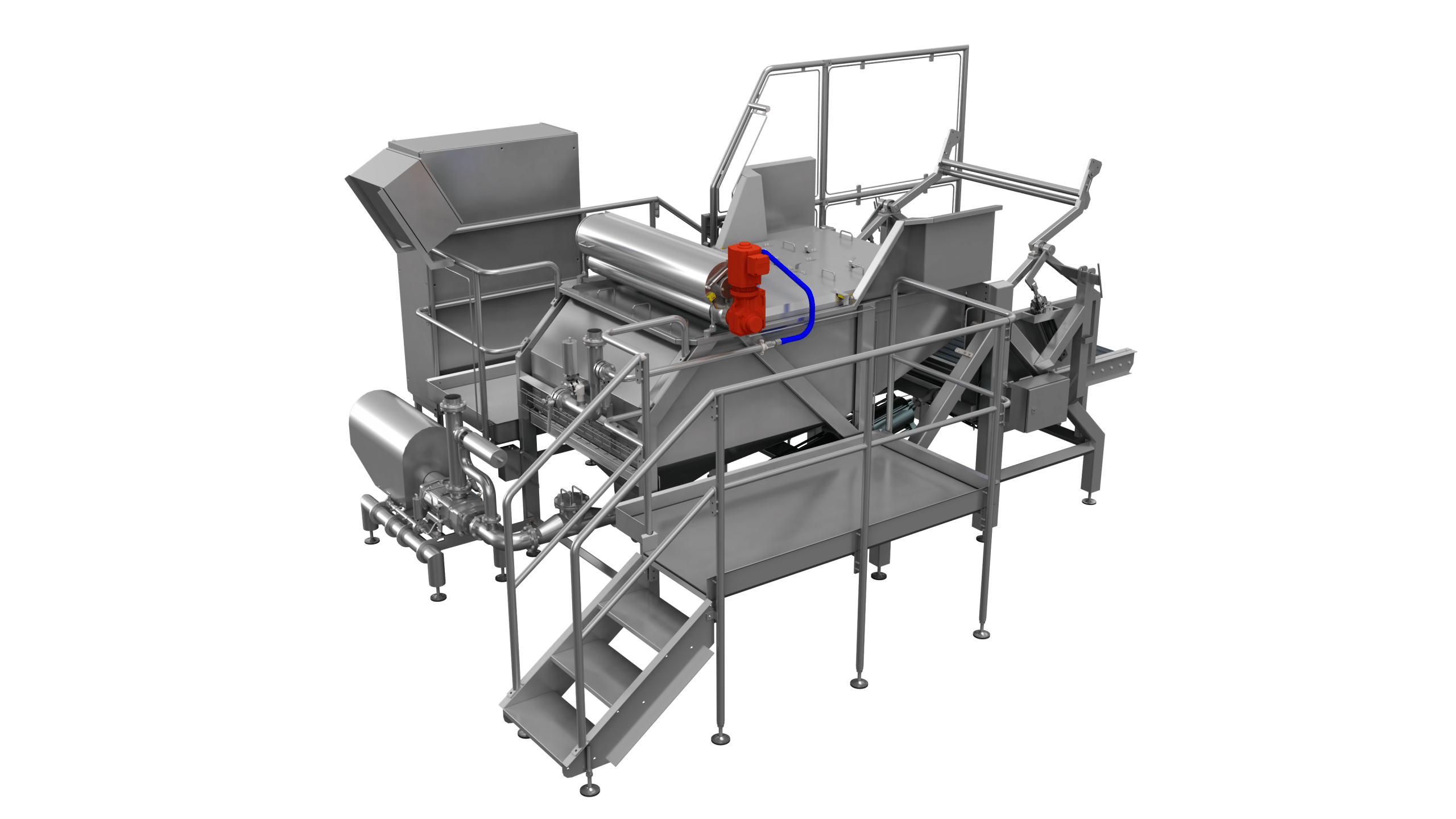

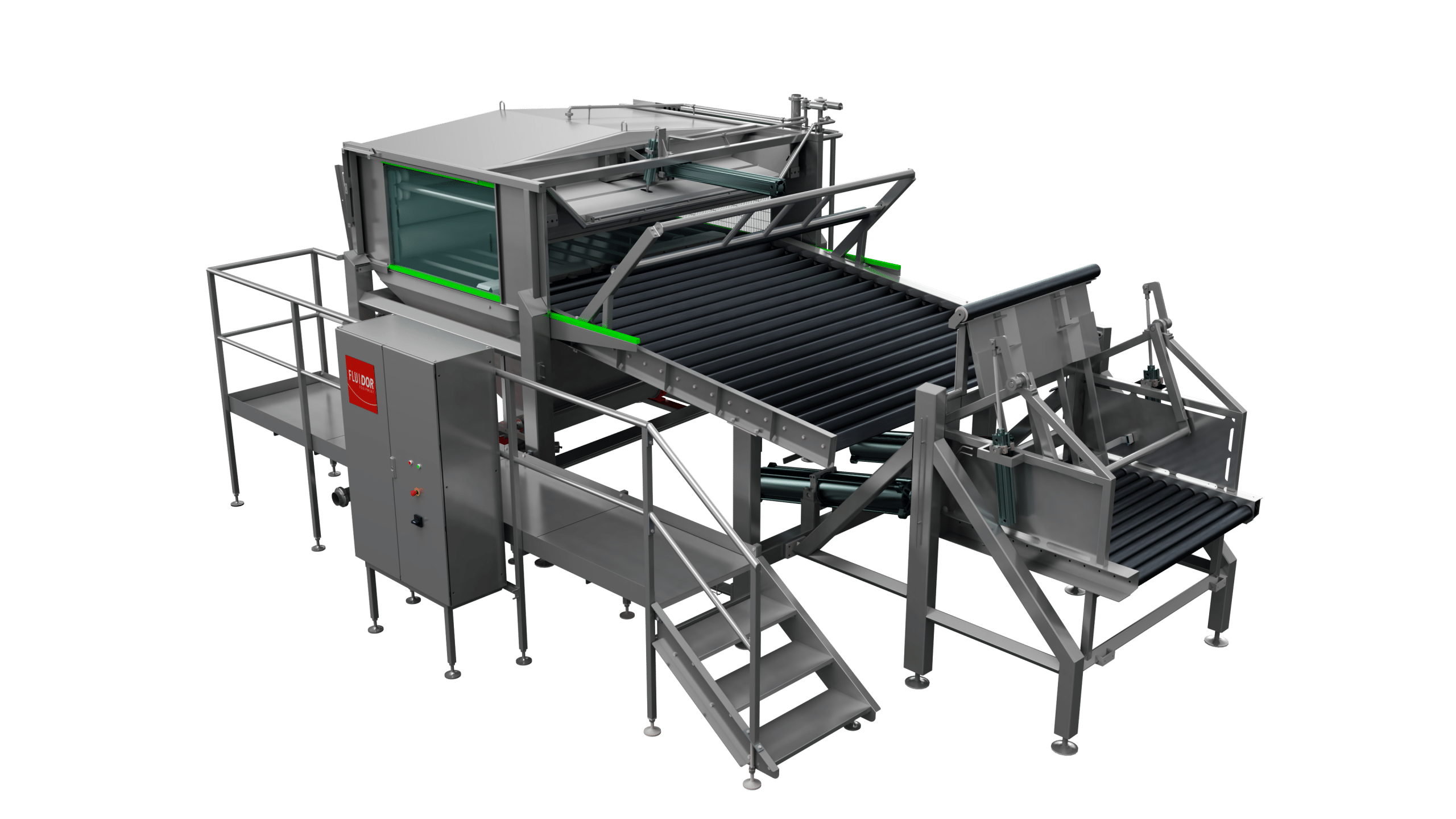

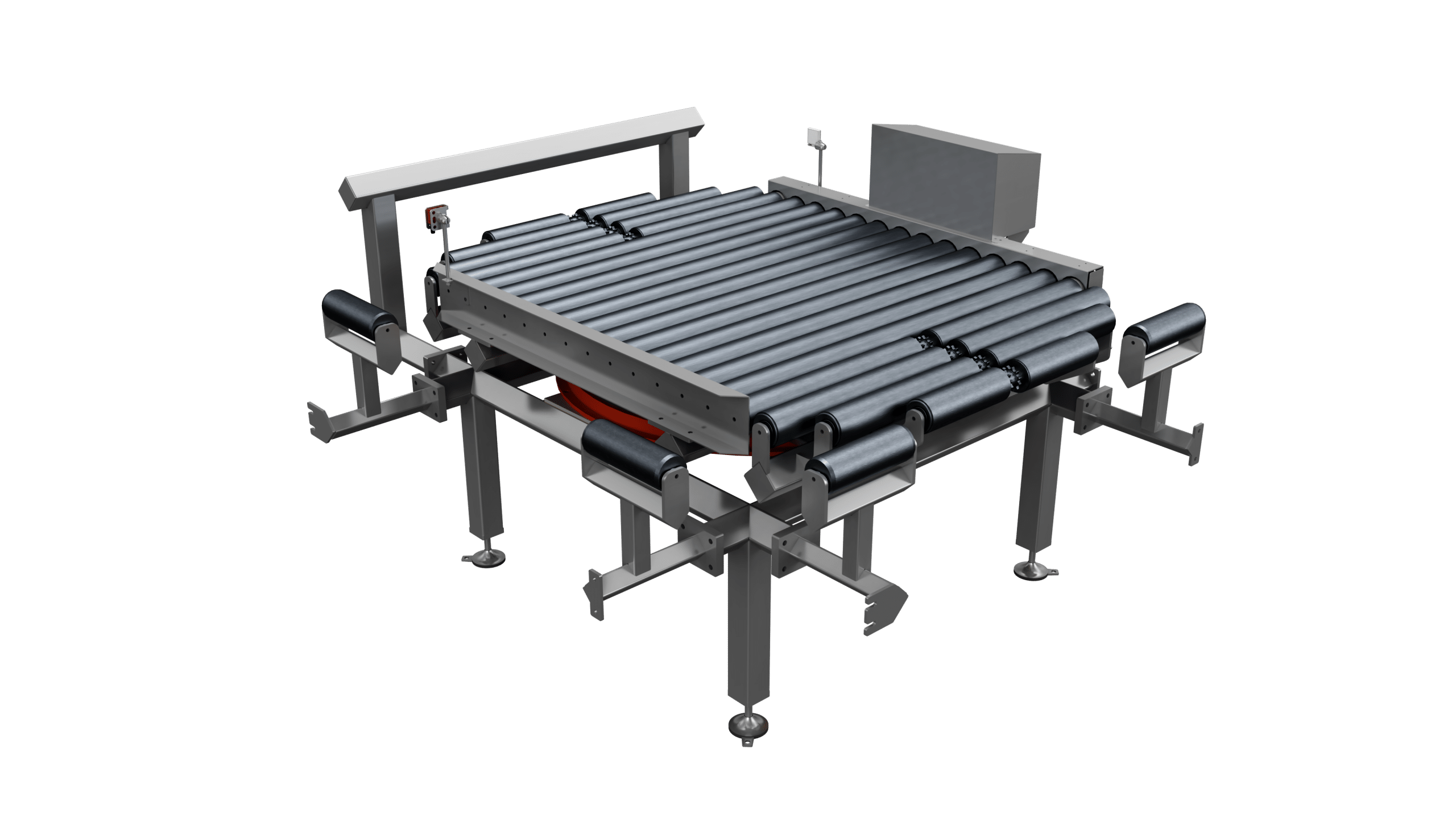

- Drums are placed on the roller conveyor section. At (optional) Drum Opening Station, the lid will be removed and liner(s) will be opened.

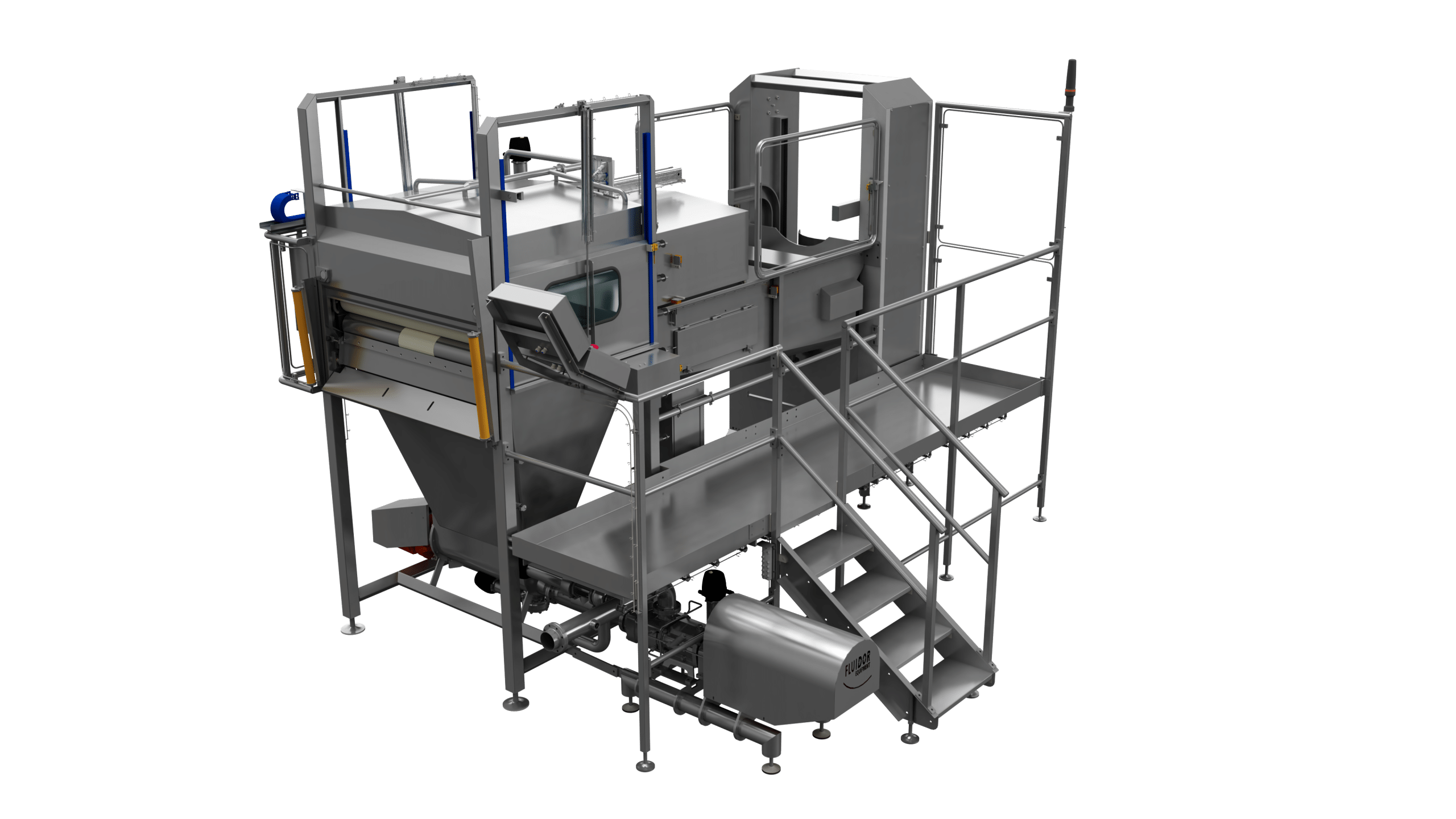

- The drum is lifted and tipped pneumatically. The bag slides into the collecting hopper and is stopped by a grid. The bag will empty itself partly.

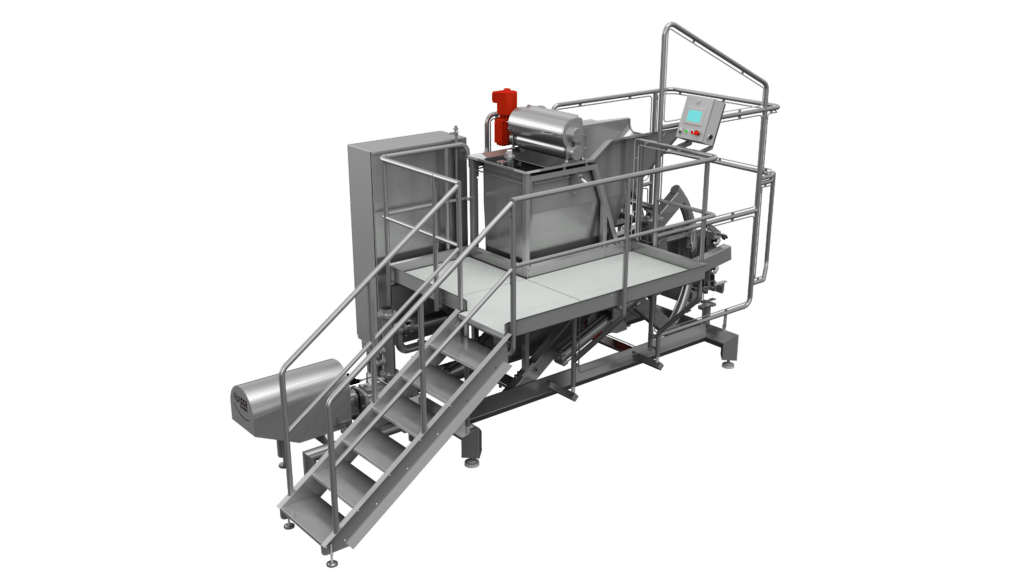

- The operator brings the bottom part of the bag into the squeezer and the remaining product is squeezed out.

- The product falls into the hopper and is discharged by a screw conveyor and twin screw pump.

The DAPS Paste efficiently empties drums without leaving significant residue. For maximum yield and less product loss, improving overall production efficiency.

The DAPS Paste reduces the likelihood of spills and splashes during dumping operations, for a safer working environment and minimal cleanup.

The DAPS Paste is compatible with various drum sizes and types, adaptable to different industrial settings for diverse production needs.